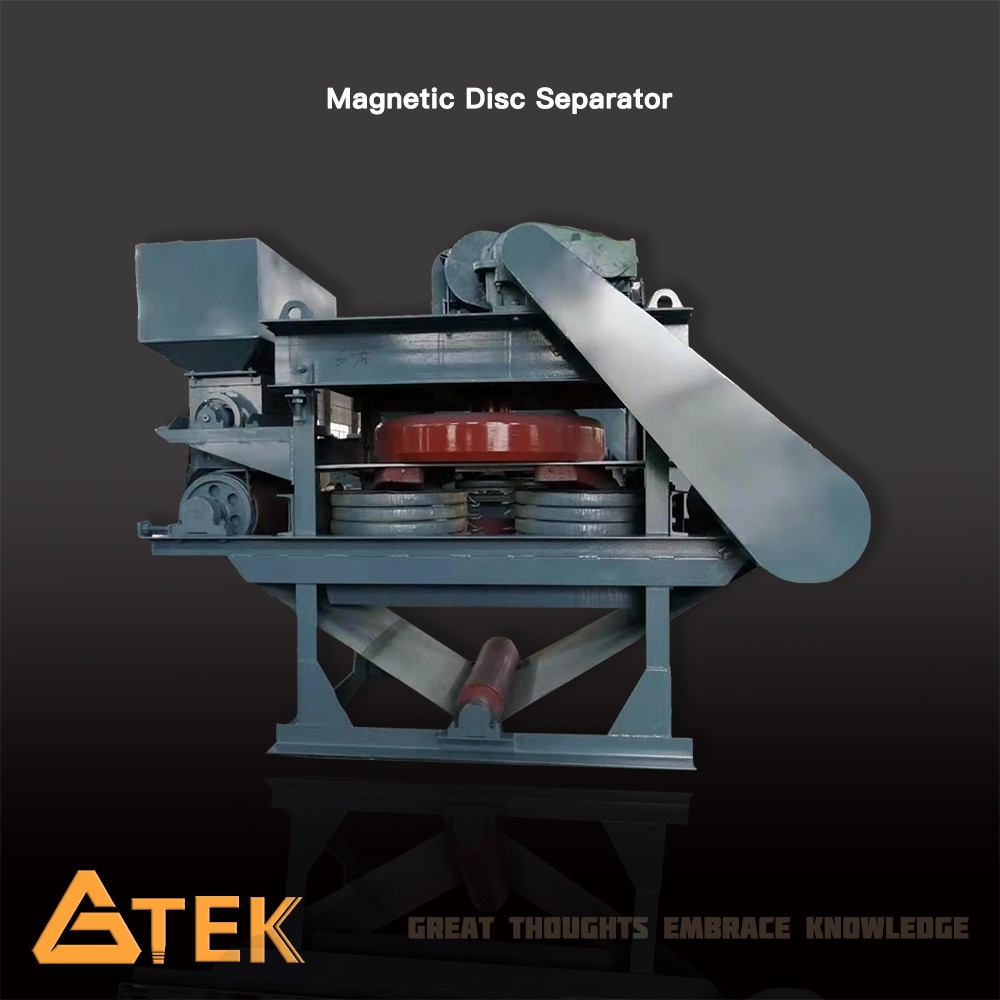

Magnetic Disc Separator

GTEK Magnetic Disc Separator is designed for continuous separation of materials that have varied magnetic susceptibilities.

Description

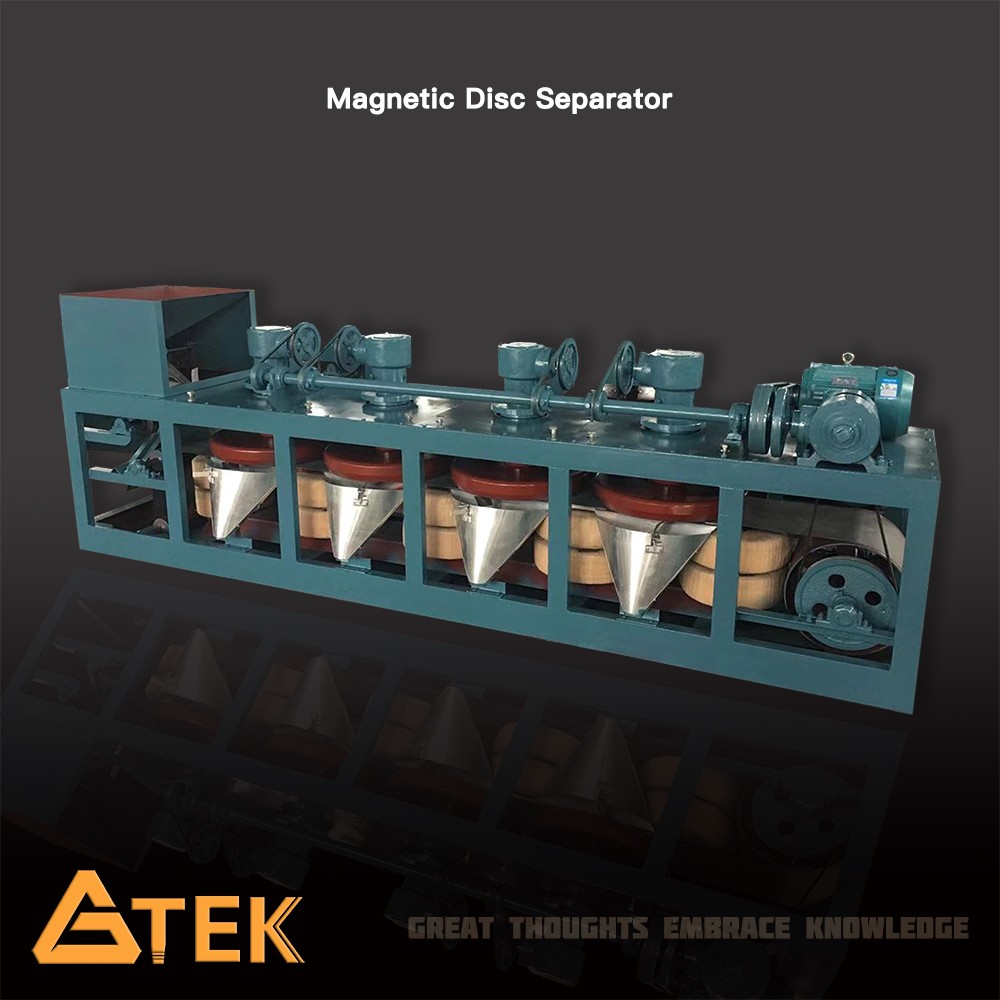

GTEK Magnetic Disc Separator or High Intensity Electromagnetic Disc Separator is designed for continuous separation of materials that have varied magnetic susceptibilities. GTEK can offer magnetic disc separator of Single Disc to Four Disc models in order to suit different applications. Each disc is designed to offer varied range of intensity. This facilitates separartion of minerals of different susceptibilities in a single operation. Magnetic intensity is variable from 0 to 20,000 gauss and can be adjusted by varying the current of each coil to suit each client's specific mineral separation requirements. Each electromagnetic disc can be set at a different height from the conveyor belt to get different magnetic force. Optimum selectivity can be accurately achieved by combining disc height adjustment with variation of coil curreny from the control panel.

Our Magnetic Disc Separatior can be used in the following application:

Concentration of dry, granular minerals such as ilmenite, gamet, monazite, wolframite, and columbite-tantalite (Coltan);

Removal of minerals of low magnetic susceptibility from cassiterite, zircon, scheelite and rutile;

Purification of quartz for the glassmaking industry;

Purification of abrasives;

Extraction of iron oxides from chenmical and food products;

Separation of different types of swarf.

Working Principle

Feed material is discharged from a hopper with magnetic drum onto the conveyor belt. A thin layer of material is continuously transported beneath the rotaing discs where magnetic particles are attracted to the high gradient magnetic zones on the discs. These captured particles are the carried by the rotating discs to the discharge chutes where they are released. Scrapers that are mounted on each of the chutes to ensure the total discharge of the extracted magnetic particles. Concentrated fractions of minerals are collected and then further processed. Any feed material that is non-magnetic will pass under each of the three or four discs and discharge at the end of the conveyor as a clean non-magnetic product.

A Magnetic Disc Separator will feature up to three high intensity electromagnetic discs, each set at a different height from a feed conveyor. The first disc will be set the furthest from the feed material, in order to extract only the most magnetically susceptible particles. The second and third discs are set at lower gaps, increasing the magnetic force at each disc and therefore separating different grades of magnetic material. Magnetic Disc Separator with four electromagnetic discs are also avaliable for higher capacity and improved effciency.

Features

1. Separation of different minerals with varying levels of magnetic susceptibility;

2. Single Disc to 4 Disc models available to cater for different applications and capacities;

3. Magnetic intensity is variable from 0 to 20,000 gauss and can be adjusted by varying the current of each coil;

4. Height adjustable revolving discs;

5. Robust support framework.

Model | CP-855 | CP3-500 | CP3-500 (rare-earth separation) | CP3-600 |

Magnetic Intensity | 1500mT at 2mm height | 1700mT at 2mm height | 2000mT at 2mm height | 1800mT at 2mm height |

Disc Quantity | 1 | 3 | 3 | 3 |

Disc Rotation Speed | 28-30r/min | 25-40r/min | 22-38r/min | 22-38r/min |

Disc Diameter | 885mm | 500mm | 500mm | 500mm |

Power | 380V 3P | 380V 3P | 380V 3P | 380V 3P |

Excitation Coil | 2 | 4 | 4 | 4 |

Excitation Power | 1.5kW | 1.5kW | 1.5kW | 1.5kW |

Max. Coil Temperature | 65℃ | 65℃ | 65℃ | 65℃ |

Rated Current of Coil | 3.5A | 1.2-1.9A | 1.2-1.9A | 1.2-1.9A |

Max. Feeding Size | 4mm | 2mm | 2mm | 2mm |

Dimension | 2500*1030*1600mm | 2800*800*1220mm | 3150*900*1250mm | 3150*900*1250mm |

Capacity | 300-1600kg/hr | 100-500kg/hr | 80-800kg/hr | 120-800kg/hr |

Weight | 3200kg | 1900kg | 2300kg | 2200kg |