Eddy Current Separator

The Eddy Current Separator is an advanced metal sorting unit that is capable of separating non-ferrous metals such as aluminum and copper from dry recyclables.

Description

The Eddy Current Separator is an advanced metal sorting unit that is capable of separating non-ferrous metals such as aluminum and copper from dry recyclables.

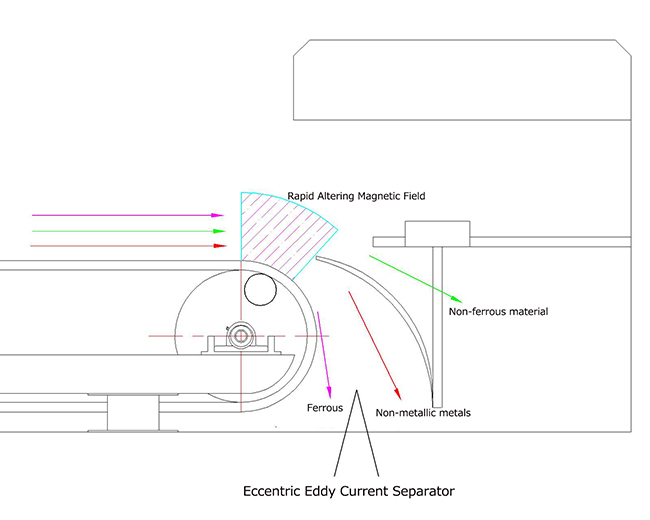

Eddy current separation is based on the use of a magnetic rotor with alternating polarity, spinning rapidly inside a non-metallic drum driving by a conveyor belt. Material is fed on to the conveyor belt of the eddy current separator, which moves it across the magnetic rotor where separation occurs. As nonferrous metals pass over the drum, the alternating magnetic field creates eddy current in the non-ferrous metal particles repelling the material away form the the conveyor. While other materials drop off at the end of conveyor, the non-ferrous metals are propelled forward over a splitter for separation.

Applications

Eddy current separation equipment can be used to remove non-ferrous metals from municipal solid waste, auto shredding residue operations, glass cullet, electric scrap, UBC reclamation, etc.

Separation of non-ferrous metals in auto shredder residue;

Separation of non-ferrous metals from solid waste incinerator ash;

Sorting of aluminum beverage cans from on-magnetic recyclables;

Removal of non-ferrous contamination from crushed glass cullet;

Separation of non-ferrous dross from foundry sand;

Non-ferrous metal removal in WEEE recycling plants;

Removal of aluminum components in UPVC window recycling;

Separation of non-ferrous metals form plastics;

Separation of non-ferrous metals form electronic scrap;

Separation of non-ferrous metals from car recycling applications.

Working Principle

An Eddy Current Separator consists of an outer drum, an internal magnetic rotor, a drive and belt conveyor.The magnetic rotor, which is positioned inside the non-conductive outer drum, revolves at around 3000 revolutions per minute during operation whilst the outer drum rotates at belt speed.

The rotation speed of magnets generates an induction field, creating a rapid changing magnetic field. The separation is based on the principle that every electrically conductive particle located in an altering magnetic field is temporarily magnetized. The polarity of that magnetic field is the same as the rotating magnet, causing the conductive particle to be repelled from magnet, this enable us to separate huge number of nonferrous material from non-metallic material.

In most applications, GTEK Eddy Current Separators are set up with other separation equipments to ensure a clean, high quality recycled product.

The machine can be controlled and adjusted via touch panel.

Features

1.Excellent recovery of heavy non ferrous metals;

2.Designed with top grade rare-earth magnetic material;

3.Adopt Intelligent touching control,VFD technology;

4.Use high quality components to ensure reliable in long-term operating;

5.Designed for minimal and easy maintenance;

6.Special magnets system protection mechanism preventing dropping off of magnets;

7.Designed for lower noise and minimal vibration

Type | Belt | Power | Weight | Size | |||||

Feeding width (mm) | Feeding length (mm) | Feeding | Capacity (m3/h) | Power (kw) | Weight (kg) | Length (mm) | Width (mm) | Height (mm) | |

GTFX-4 | 400 | 1500 | ≥1 mm2 | 4 | 7 | 600 | 4600 | 1660 | 1700 |

GTFX-5 | 500 | 6 | 730 | 1760 | |||||

GTFX-6 | 600 | 10 | 895 | 1860 | |||||

GTFX-6.5 | 650 | 15 | 950 | 1910 | |||||

GTFX-8 | 810 | 20 | 1225 | 2060 | |||||

GTFX-10 | 1015 | 25 | 1555 | 2260 | |||||

GTFX-12 | 1215 | 30 | 1875 | 2460 | |||||

GTFX-14 | 1420 | 1800 | 35 | 2275 | 4900 | 2660 | |||

GTFX-16 | 1600 | 2000 | 40 | 2850 | 5100 | 2860 | |||