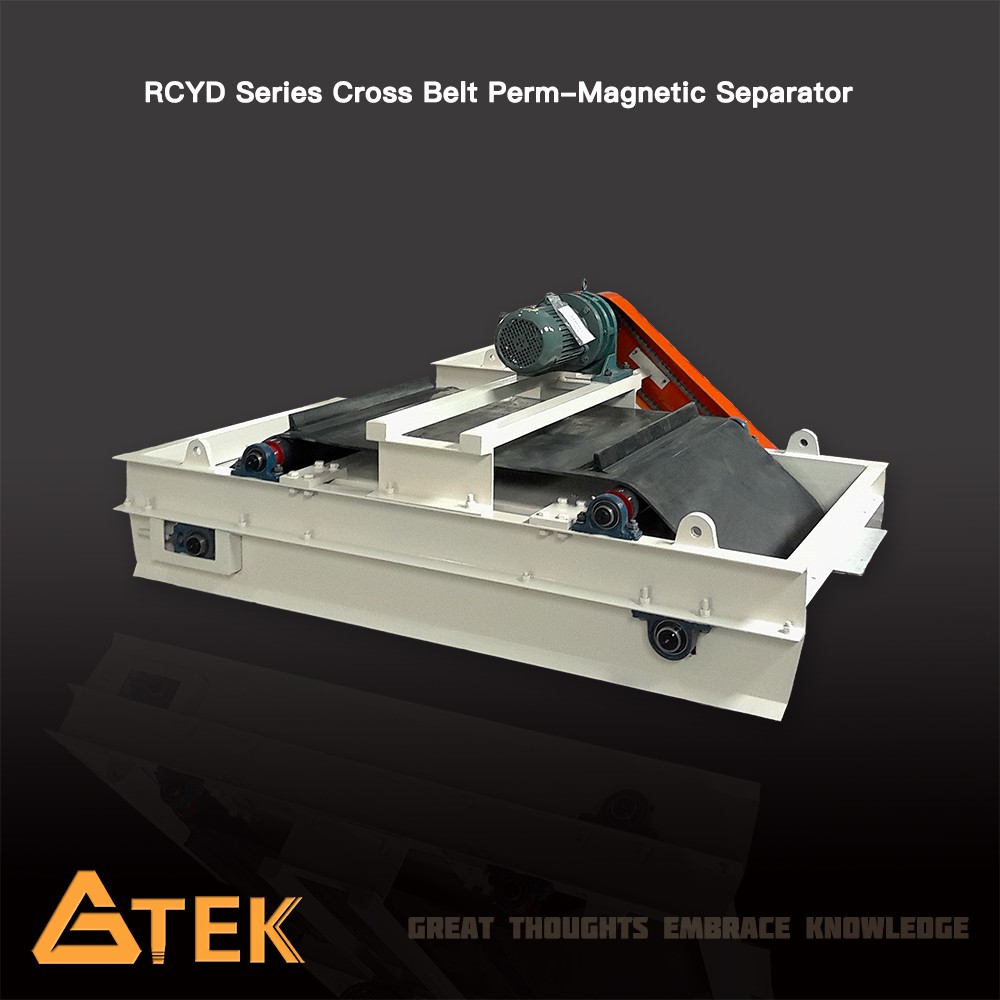

RCYD Cross Belt Magnetic Separator

GTEK RCYD self-unloading cross belt magnetic separator is a suspended permanent magnet with a continuously running belt and is designed for separation of ferrous metal on a variety of over-the-belt conveyor applications.

Description

GTEK RCYD self-unloading cross belt magnetic separator is a suspended permanent magnet with a continuously running belt and is designed for separation of ferrous metal on a variety of over-the-belt conveyor applications. GTEK designed and manufactured cross belt separators to provide industry with a reliable and extremely effective means of metal extraction.The cross belt magnet is manufactured with a powerful plate magnet, heavy duty steel frame, vulcanized rubber cleated belt, a motor and reducer. The magnet may be suspended either cross belt (perpendicular to the product flow) or inline (parallel above the product flow).

Depending on the different application environment. We also provide other options as below:

RCYK Armour Cross Belt Perm-Magnetic Separator

Application: Specially used in Iron Separation of metallurgical slag, prevent belt damage to sharp magnetic debris.

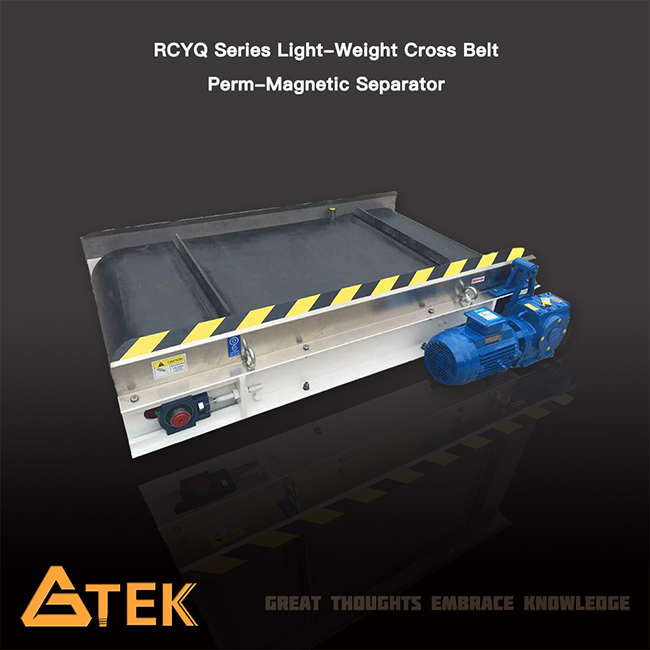

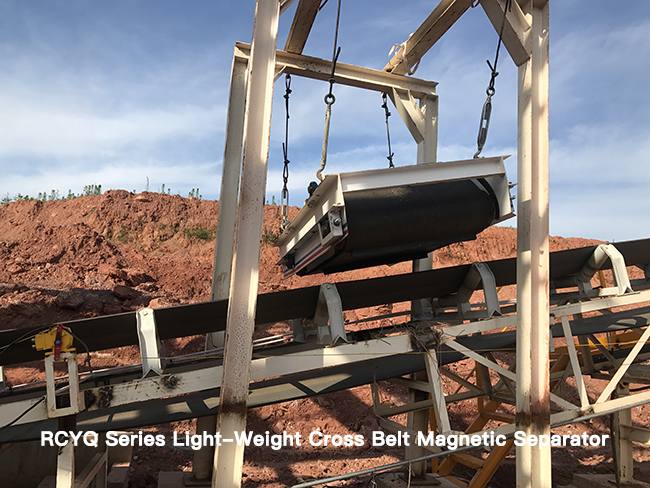

RCYQ Light-Weight Cross Belt Perm-Magnetic Separator

Advantages: Less cubage and wealth,a good helper for iron removal in environmental protection, wood industry, grain, casting, chemical industry, building materials, mining, light industry and other industries.

Working Principle

The major components of RCYD Series Cross Belt Magnetic Separator are a Permanent magnet with a continuously running belt. When the ferrous matels pass through the high intensity magnetic area, they will be absorbed to the running belt by magnetic force and be transported to non-magnetic area where they fall off. So that the RCYD Series Cross Belt Magnetic Separator can separate ferrous matels from others constantly.

Features

1. Rare Earth magnetic material used, creating a permanent magnet with maximum field depth for the size and application required;

2. No power needed to run the magnetic field;

3. Belt options available (armoured for sharp contamination);

4. Good for heavy contaminated products;

5. Different magnetic strengths for difference suspension heights to fit your applications;

6. Sizes to fit for any belt width;

7. Special requirements can be custom built.

Model | Adaptive belt width(mm) | Suspension height (mm) | Material thickness (≤mm) | Magnetic field intensity (≥mT) | Driving Power (≤kw) | Adaptive belt speed (m/s) | Weight(kg) | Dimension(mm) L W H | ||

RCYD-5 | 500 | 150 | 80 | 60 | 1.5 | ≤2.5 | 750 | 1600 | 820 | 850 |

RCYD-6 | 600 | 175 | 125 | 60 | 1.5 | 920 | 1700 | 920 | 850 | |

RCYD-6.5 | 650 | 200 | 150 | 70 | 1.5 | 1200 | 1750 | 970 | 850 | |

RCYD-8 | 800 | 250 | 200 | 70 | 2.2 | 1400 | 1900 | 1150 | 900 | |

RCYD-10 | 1000 | 300 | 250 | 70 | 3.0 | 2120 | 2140 | 1350 | 950 | |

RCYD-12 | 1200 | 350 | 300 | 70 | 4.0 | 3350 | 2340 | 1550 | 950 | |

RCYD-14 | 1400 | 400 | 350 | 70 | 4.0 | 4450 | 2600 | 1750 | 950 | |

RCYD-16 | 1600 | 450 | 400 | 70 | 5.5 | 6200 | 3420 | 1180 | 2210 | |

RCYD-18 | 1800 | 500 | 450 | 72 | 5.5 | 8100 | 3580 | 1210 | 2450 | |

RCYD-20 | 2000 | 550 | 500 | 72 | 7.5 | 9700 | 3800 | 1300 | 2700 | |