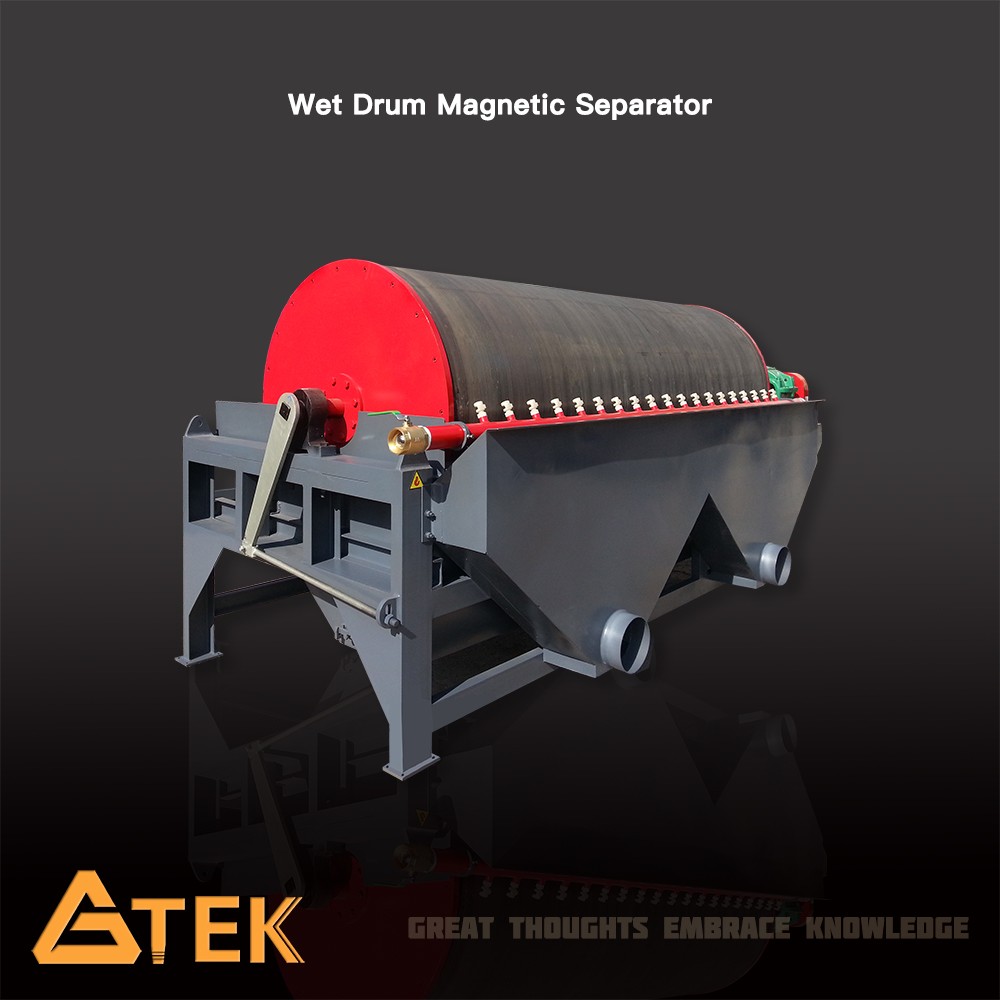

Wet Drum Magnetic Separator

Wet Drum Magnetic Separator can be used for recovery of fine and strong magnetic minerals or removal of small amounts of ferromagnetic materials from non-magnetic minerals.

Description

Wet Drum Magnetic Separator can be used for recovery of fine and strong magnetic minerals or removal of small amounts of ferromagnetic materials from non-magnetic minerals. Wet Drum Magnetic Separator is suitable for beneficiation of magnetite, pyrrhotite, hematite, limonite, siderite, etc. Different tank styles are available to meet varying requirements of customers.

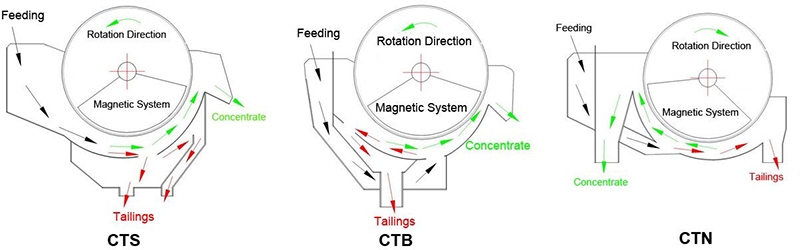

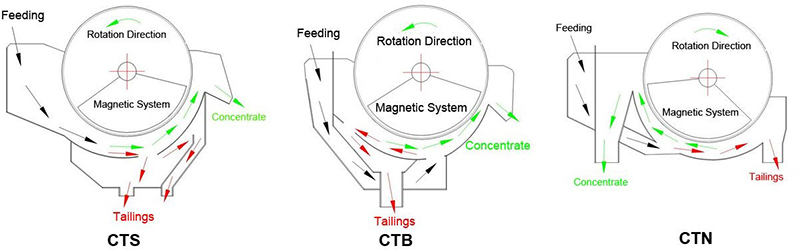

Three different style available with Concurrent tank/ Countercurrent tank/ Counter-rotation tank

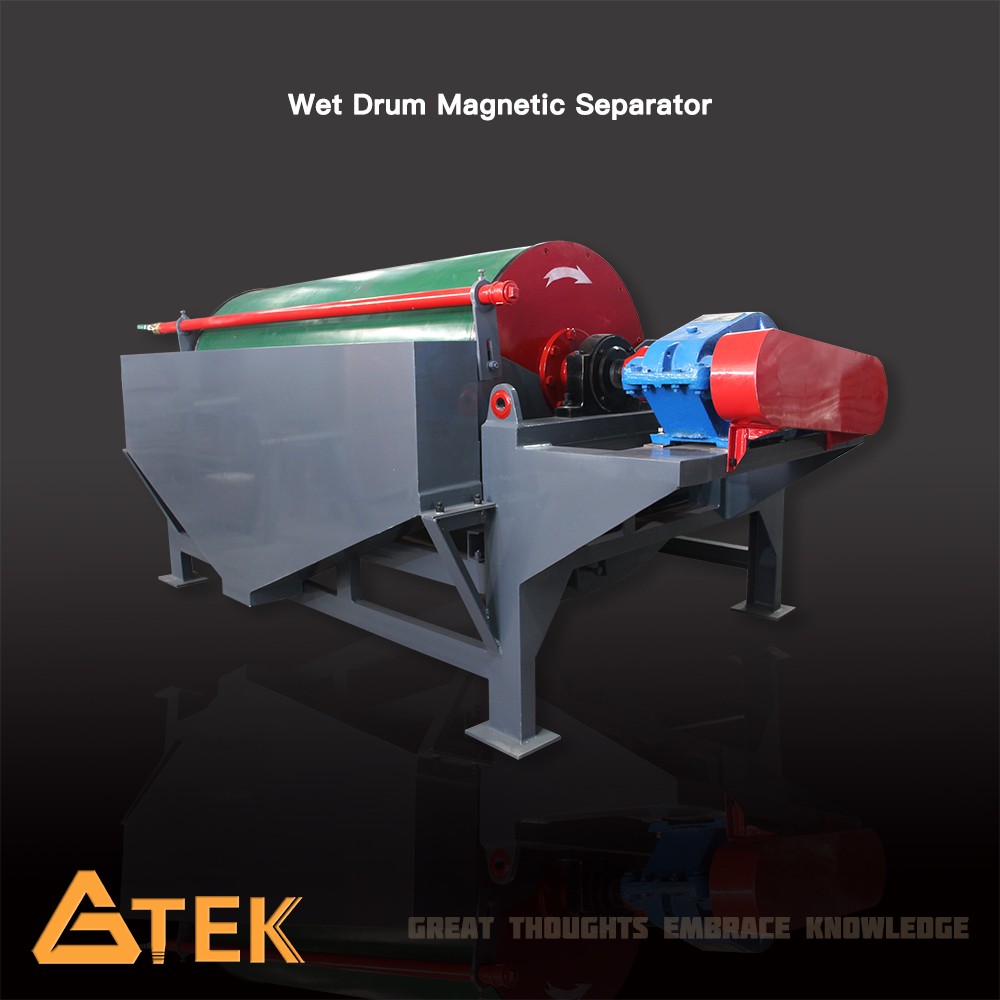

1. The CTS seires is concurrent tank style, it is designed for handling minerals with particle sizes from 0-6mm;

2. The CTN series is countercurrent tank style, it is designed for handling mineralss with particle sizes from 0.6-6mm;

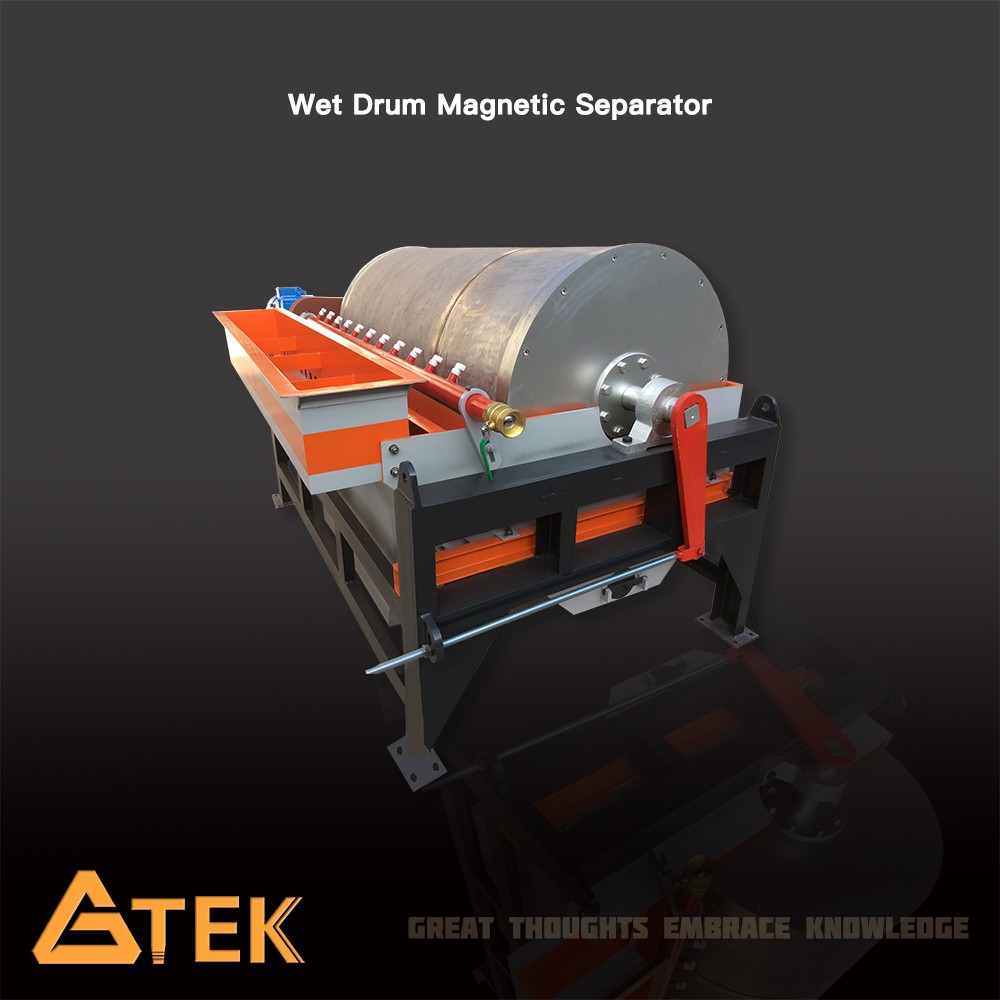

3. The CTB series is counter-rotation tank style, it is designed for handling minerals with particle sizes from 0-0.5mm,especially for mineral with particle size from 0-0.15mm.

Concentrate Discharging Port

Slurry Feeding Port

Working Principle

Magnetic separation is used to separate minerals based on their magnetic properties. When wet drum magnetic separaotor is working, slurry is fed to the tank and subsequently flows through the magnetic field generated by the drum. The ferromagnetic minerals are attracted to the drum surface by the magnetic circuit and are rotated out of the slurry stream. The ferromagnetic discharge from the drum surface when rotated out of the magnetic field.

Features

1. Using Permanent Magnets;

2. Magnetic Intensity: 0.2T as per your requirement Position of magnetic yoke adjustable;

3. Drum Rotation speed adjustable;

4.Three different style available Concurrent tank/ Countercurrent tank / Counter-rotation tank.

Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Rotation Speed (r/min) | Feeding Size (mm) | Processing Capacity (t/h) | Power (KW) |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |