Spiral Classifier

Spiral Classifier is one of the beneficiation devices based on the differing of solid particles in specific gravities.

Description

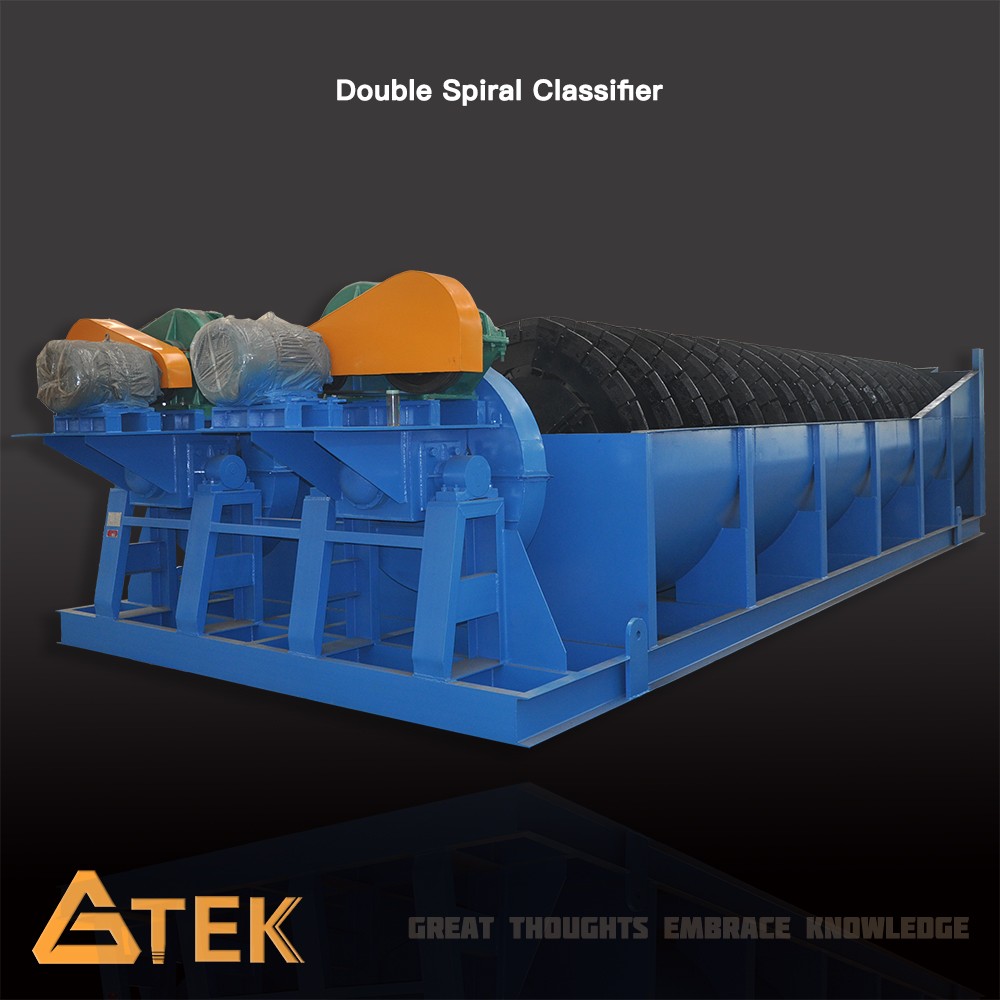

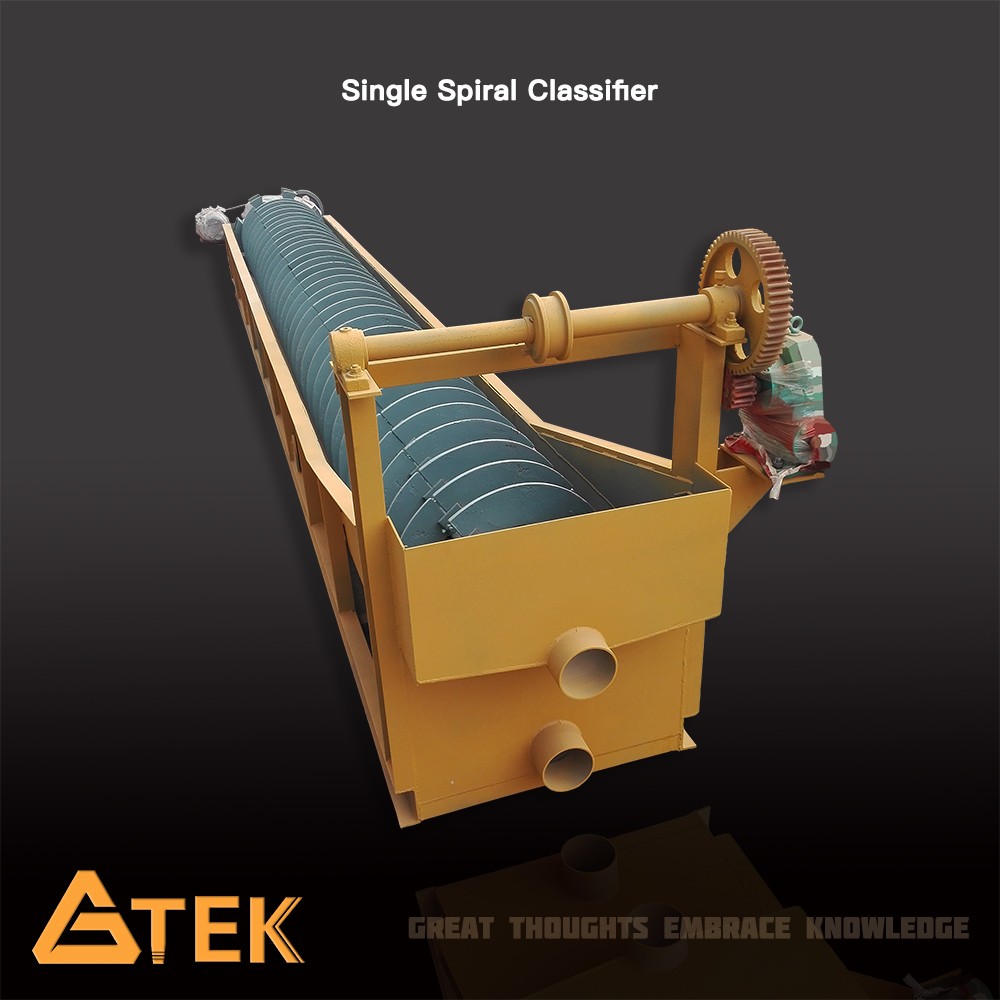

Spiral Classifier/ Screw Classifier is one of the beneficiation devices. Spiral Classifier achieves the purpose of classification based on the differing of solid particles in specific gravities. Spiral Classifiers mainly include four types. They are high weir type single spiral classifier, high weir type double spiral classifier, immersed type single spiral classifier and immersed type double spiral classifier. GTEK spiral classifier has the characteristic of simple structure, reliable working and easy operation.

Spiral Classifier has been widely use in closed-circuit grinding operations and it can also be used for the classification of ore sand and slime in gravity beneficiation plants, for the size grading of slurry in mineral processing plants and for desliming and dewatering in ore-washing plants.

Working Principle

The motion of the spiral creates pool hindered settling in the bottom pool area, and the agitation of water keeps the fines suspending in the liquid, while the coarser particles settle on the spiral and be transported to the discharge which located at the top of the classifier. Then gravity flow or pumps are used to move the coarse material to the next stage in the process, the finer particles overflow from the pool area. The pool area normally has an adjustable weir, which will determine the amount of time material is in the pool area, and subsequently the coarseness of the discharge from the pool area, with a shorter residence time the coarser the discharge, along with the fines.

Features

1. simple structure;

2. reliable working;

3. easy operation.

Model | Spiral Diameter

| Length of pool | Rotation Speed (r/min) | Motor Power(kw) | Dimensions(mm) | Weight (t) | |||

Drive | Lift | L | W | H | |||||

FG-3 | 300 | 3000 | 12-30 | 1.1 | -- | 3850 | 490 | 1140 | 0.7 |

FG-5 | 500 | 4500 | 8-12.5 | 1.1 | -- | 5430 | 680 | 1480 | 1.6 |

FG-7 | 750 | 5500 | 6-10 | 3 | -- | 6270 | 980 | 1820 | 2.7 |

FG-10 | 1000 | 6500 | 5-8 | 5.5 | -- | 7590 | 1240 | 2380 | 4 |

FC-10 | 8400 | 7.5 | 9600 | 1240 | 2680 | 6 | |||

FG-12 | 1200 | 6500 | 4-6 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

FC-12 | 8400 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11 | ||

2FG-12 | 6500 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

2FC-12 | 8400 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

FG-15 | 1500 | 8300 | 4-6 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

FC-15 | 10500 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

2FG-15 | 8300 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

2FC-15 | 10500 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

FG-20 | 2000 | 8400 | 3.6-5.5 | 11-15 | 3 | 10790 | 2530 | 4490 | 20.5 |

FC-20 | 12900 | 11-15 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

2FG-20 | 8400 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

2FC-20 | 12900 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

FG-24 | 2400 | 9130 | 3.67 | 15 | 3 | 11650 | 2910 | 4970 | 25.7 |

FC-24 | 14130 | 18.5 | 4 | 16580 | 2930 | 7190 | 41 | ||

2FG-24 | 9130 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

2FC-24 | 14130 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

2FG-30 | 3000 | 12500 | 3.2 | 40 | 8 | 16020 | 6640 | 6350 | 73 |

2FC-30 | 14300 | 17091 | 8680 | 84.8 | |||||