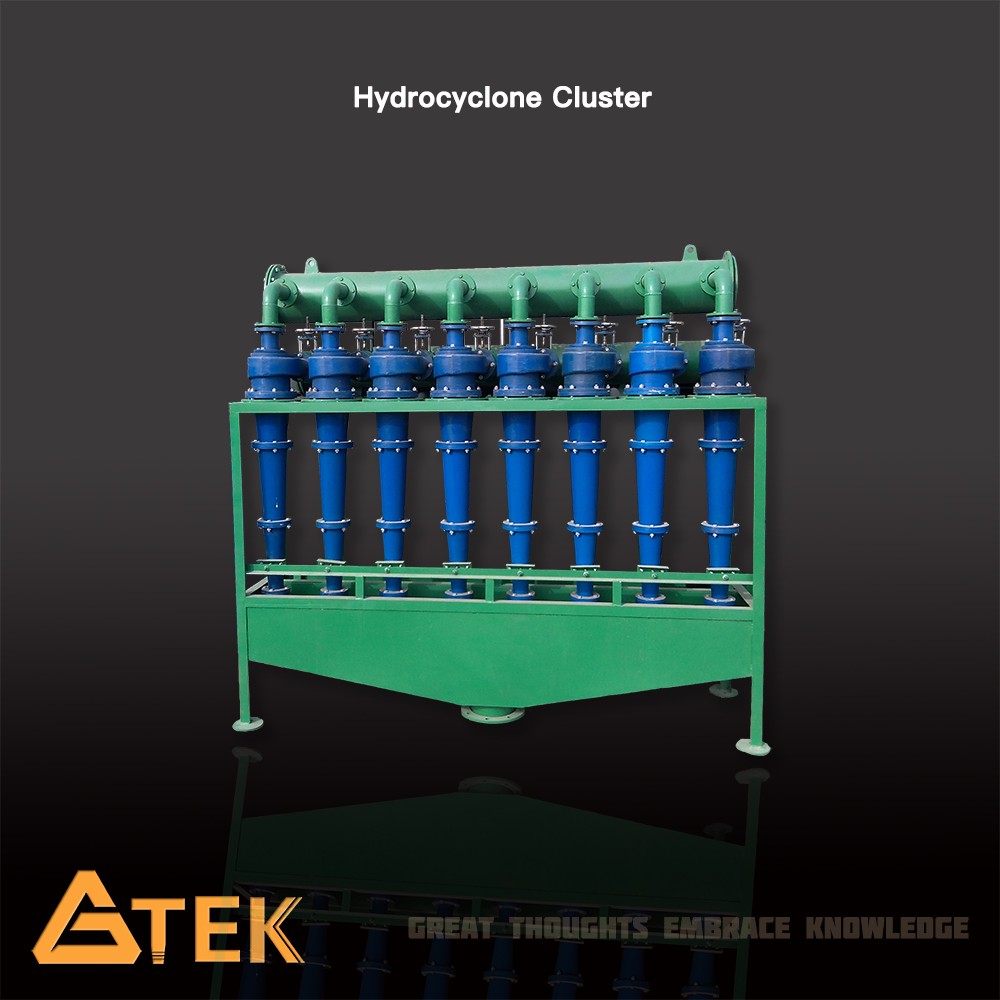

Polyurethane Hydrocyclone

Hydrocyclone is a continuously device that utilizes centrifugal force to accelerate the settling rate of particles.

Description

Hydrocyclone is a continuously device that utilizes centrifugal force to accelerate the settling rate of particles. GTEK manufactures polyurethane hydrocyclones which are designed for separating solids from liquids and has proved to be successful in a board range of mineral processing applications. All GTEK hydrocyclones have a range of interchangeable vortex finders and spigots in different sizes and materials, allowing for optimization of separation.

GTEK Polyurethane Hydrocyclone can be used in widely applications, such as: Sand and Slit Removal, Mineral Classification, Solids Concentration, Sludge Classification, Soil Washing and Separation, Dewatering, Desliming.

Working Principle

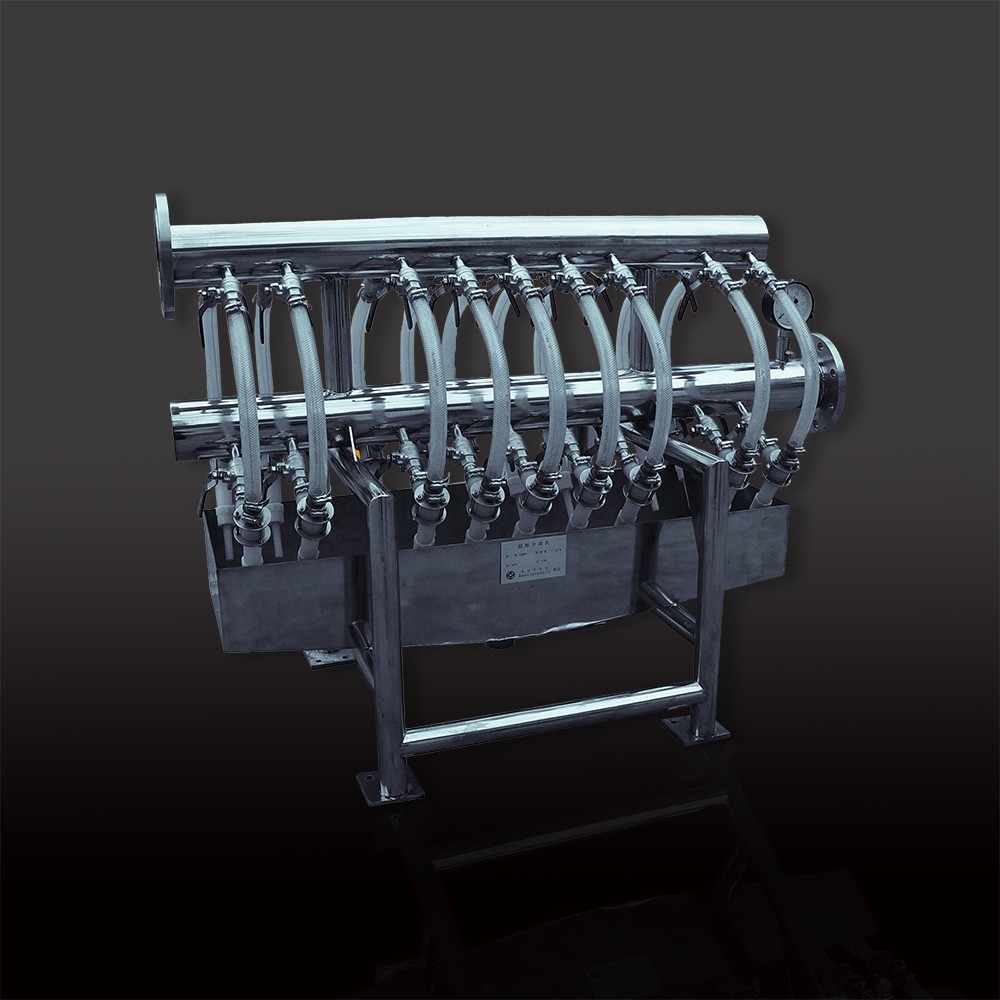

A hydrocyclone is a device designed for material separation and concentration, which could be soild, liquid or gas of different density, by means of centrifugal forces. Production-Type Hydrocyclone are usually made of polyurethane or steel with ceramic or rubber lined. There are two discharge exits on the axis, one on the bottom which is called underflow or the spigot, and the other one at the top which is called overflow or the vortex finder. Internally, the larger or denser particles are transported to the wall for eventual exit at the underflow side, while the finer or less dense particles, remain in the liquid and exit at the overflow side through a tube at the center of the cyclone.

Features

1. Abrasive resistance urethane;

2. Fine Micron separation;

3. No moving parts

4. Small space requirements;

5. Easy to install and simple to operate;

6. Low maintenance;

7. Easy to service with tie bolts & Clamp design

Model | Interior Diameter (mm) | Cone Angle | Overflow Diameter (mm) | Feed Size (mm) | Feed Pressure (Mpa) | Process Capacity (m3/h) | Range (um) | Dimensions (L*W*H)(mm) | ||

HC300-GJ | 300 | 20 | 80-120 | 6 | 0.04-0.3 | 60-100 | 50-150 | 775 | 605 | 1765 |

15 | 50-120 | 775 | 605 | 2115 | ||||||

HC250-PU | 250 | 20 | 65-115 | 5 | 0.04-0.3 | 45-85 | 50-150 | 665 | 585 | 1310 |

15 | 40-100 | 665 | 585 | 1505 | ||||||

HC200-PU | 200 | 20 | 60-100 | 3 | 0.06-0.35 | 40-60 | 40-100 | 540 | 480 | 1180 |

15 | 40-100 | 540 | 480 | 1220 | ||||||

10 | 30-100 | 540 | 480 | 1380 | ||||||

HC150-PU | 150 | 20 |

40-65 | 2 | 0.06-0.35 | 25-40 | 40-100 | 435 | 360 | 1050 |

15 | 30-100 | 435 | 360 | 1115 | ||||||

10 | 30-100 | 435 | 360 | 1205 | ||||||

HC125-PU | 125 | 20 | 30-45 | 1.5 | 0.06-0.35 | 11-20 | 30-74 | 280 | 295 | 690 |

15 | 30-74 | 280 | 295 | 900 | ||||||

8 | 30-74 | 280 | 295 | 1270 | ||||||

HC100-PU | 100 | 17 | 25-40 | 1 | 0.06-0.35 | 8-15 | 20-100 | 210 | 185 | 620 |

8 | 20-74 | 250 | 240 | 985 | ||||||

HC75-PU | 75 | 20 | 20-40 | 1 | 0.06-0.35 | 5-12 | 20-100 | 260 | 210 | 525 |

15 | 20-100 | 268 | 215 | 720 | ||||||

8 | 20-100 | 268 | 215 | 1000 | ||||||

HC50-PU | 50 | 15 | 15-22 | 0.6 | 0.1-0.4 | 2-5 | 20-74 | 240 | 230 | 465 |

6 | 5-40 | 240 | 230 | 800 | ||||||

HC25-PU | 25 | 15 | 11-16 | 0.3 | 0.1-0.4 | 1-2 | 10-74 | 160 | 155 | 350 |

6 | 5-30 | 160 | 155 | 590 | ||||||

HC10-PU | 10 | 6 | 3-4 | 0.2 | 0.1-0.4 | 0.1-0.2 | 2-10 | 30 | 30 | 195 |