Three Product Dense Medium Cyclone

GTEK dense medium cyclone is widely used in the coal, iron ore and diamond industries for dense medium separation.

Description

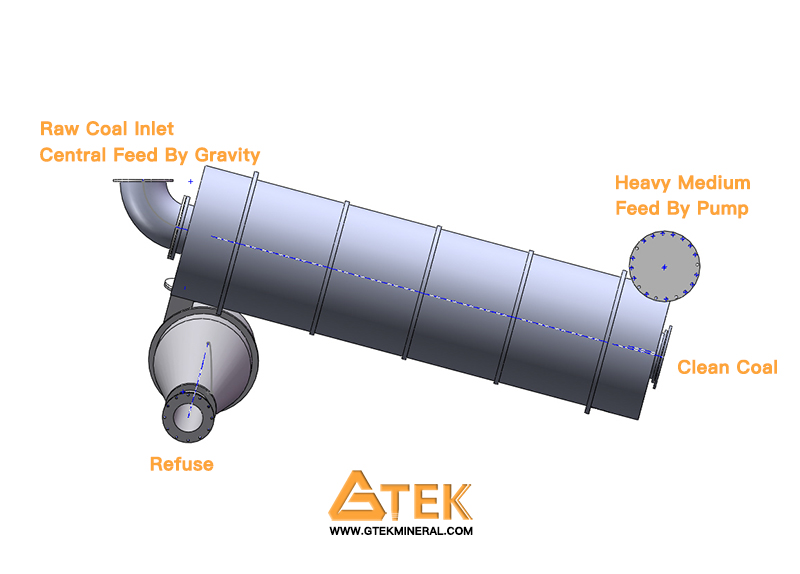

Dense medium cyclone is a kind of device which utilize centrifugal force to separate materials according to specific gravity in the medium. The raw material to be treated is suspended in a very fine medium. The pulp is fed to three product dense medium cyclone through the inlet to short cylindrical section by the force of gravity. Separation is made in the cone-shaped part of the cyclone. Gtek gravity feed three product dense medium cyclones are capable of not only separating coal particles but also concentrating and the heavy media at the same time, which makes it possible to use single low density heavy medium, instead of using both low and high densities, to produce three qualified clean, middling, and reject products at one time. The first stage cyclone is in cylinder shape which makes density field uniform and materials separated accurately based on the given heavy medium density. The second stage cyclone with conventional (cylinder + con) shape is designed to enlarge separation density difference between the two stages in order to achieve high separation density in the second cyclone.

GTEK dense medium cyclone is widely used in the coal, iron ore and diamond industries for dense medium separation.

Three Product Dense Medium Cyclone using in Coal Upgradation

Working Principle

The first stage cyclone is in cylinder shape which makes density field uniform and materials separated accurately based on the given heavy medium density. The second stage cyclone with conventional (cylinder + con) shape is designed to enlarge separation density difference between the two stages in order to achieve high separation density in the second cyclone.

Features

1. There is no requirement for desliming and sizing of raw coal fed to dense medium cyclone circuit

2. Raw coal is fed to the center of cyclone under the force of gravity, and medium is admitted tangentially by pumps.

3. Using single low density heavy medium suspension to accurately separate the run-of-mine coal into qualified clean coal, middling, and refuse products.

4. High precision and maximum efficiency of separation, suitable for preparation of difficult to clean coals

5. Little breakage impact raw coal feed, which reduces slime produced during the preparation

6. Manufactured from mild steel and lined with wear resistant alumina tiles, compact structure, easy operation and with little possibility of blockage.

7. Lower capital investment and reduced operating cost.

Model | Cylinder dia. of the first sector(mm) | Cylinder dia. of the second sector (mm) | Feeding Size(mm) | Working pressure (Mpa) | Processing Capacity (t/h) |

1400/1050 | 1400 | 1050 | ≤100 | 0.17~0.33 | 350~500 |

1300/920 | 1300 | 920 | ≤90 | 0.15~0.28 | 300~450 |

1200/850 | 1200 | 850 | ≤85 | 0.13~0.25 | 280~400 |

1100/780 | 1100 | 780 | ≤75 | 0.12~0.22 | 230~350 |

1000/700 | 1000 | 700 | ≤70 | 0.11~0.19 | 180~300 |

900/650 | 900 | 650 | ≤65 | 0.10~0.17 | 130~240 |

850/600 | 850 | 600 | ≤60 | 0.09~0.15 | 100~180 |

700/500 | 700 | 500 | ≤50 | 0.08~0.13 | 70~120 |

600/400 | 600 | 400 | ≤40 | 0.07~0.11 | 50~70 |

500/350 | 500 | 350 | ≤35 | 0.06~0.10 | 25~50 |