Slurry Pumps

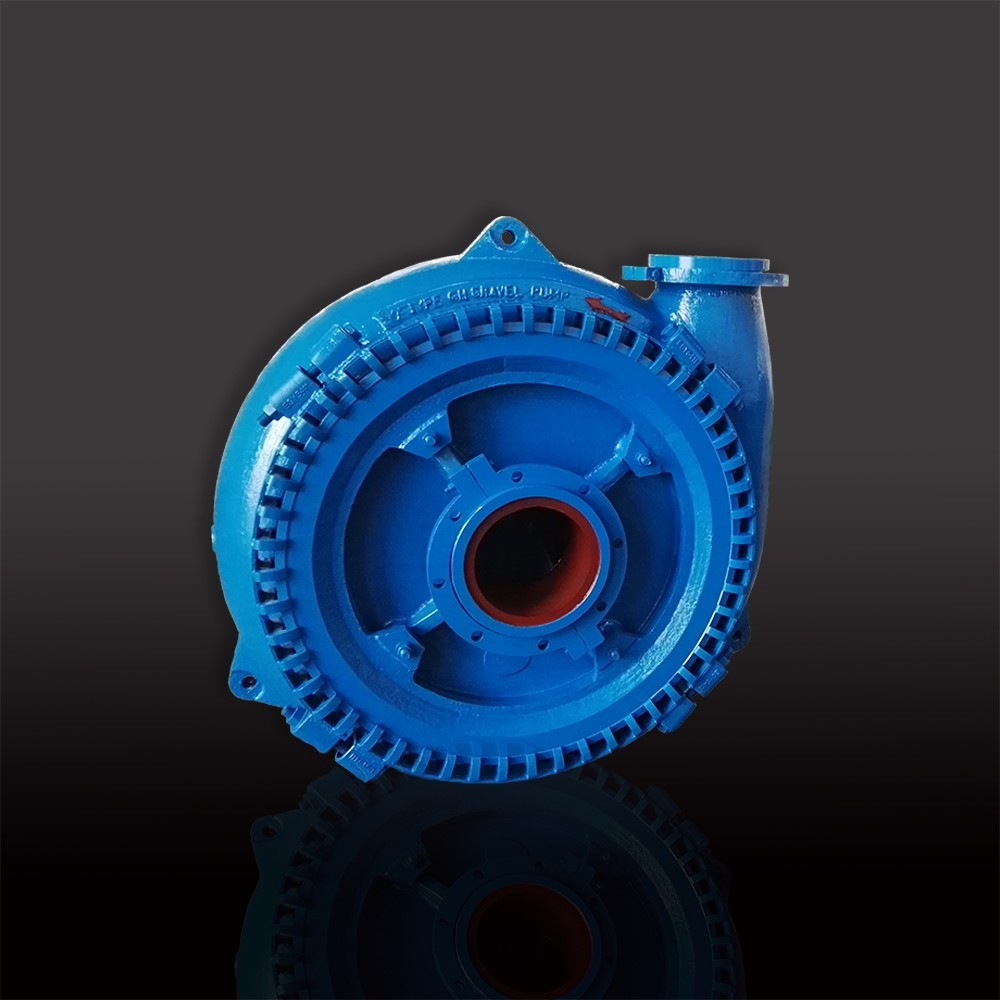

GTEK AH Heavy Duty Slurry Pumps are end suction, split-case, centrifugal pumps and are designed for heavy duty abrasive applications.

Description

GTEK AH Heavy Duty Slurry Pumps are end suction, split-case, centrifugal pumps and are designed for heavy duty abrasive applications, with large shaft diameter, heavy duty bearing assemblies and robust slurry pumping capacity. Our AH Series Slurry Pumps are available in a wide range of sizes and models, with a variety of metal and rubber parts options, an assortment of seal arrangements, and a standard impeller adjustment mechanism incorporated into every base or assembly.

AH Heavy Duty Slurry Pumps specialize in handling the toughest and most abrasive applications which include mining, mineral processing, power generation, aggregate processing, or any type of slurry pumping application.

Typical Applications:

•Mineral Processing

•Coal Preparation

•Cyclone Feeds

•Aggregate Processing

•Fine Primary Mill Grinding

•Process chemical

•Tailings

•Industrial Processing

•FGD

•Pulp and paper

•Food Processing

•Ash Handling

•Rod mill discharge

•SAG mill discharge

Working Principle

Features

WETTED PARTS

IMPELLERS–Interchangeable metal and rubber impellers available. Pump out vanes on rear and front reduce recirculation within pump, which prevents seal contamination.

LINERS–Interchangeable metal and rubber liners available Easily replaceable liners are attached to casing by threaded bolts rather than unreliable glue.

THROATBUSH –Interchangeable metal and rubber throat bush– adjustable via cotters to account for wear over time and increase efficiency.

SEALS–GTEK offers a wide variety of seal options to suit any process requirements

EXPELLER (CENTRIFUGAL SEAL)–available with low flow water flush or zero flow (grease lubricated) options to provide exceptional sealing where water introduction to the seal is intolerable or limited.

STUFFING BOX–gland sealing with packing and lantern ring.

MECHANICAL SEALS

BEARING ASSEMBLY–Large shaft diameters and reduced overhang in the wet end contribute to long life and reliability in the field.

CASING–Split-case design allows for ease of access and maintenance on wet end parts. Cast ductile iron with exterior ribbing provides increased pressure ratings and reliable service over time.

BASE–A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

Model | Allowable Max.PowerP(Kw) | Clear Water Performance | Impeller | |||||

Capacity Q | Head H(m) | Speed n(r/min) | Top Efficiencyη% |

NPSH(m) | Impeller Diameter D(mm) | |||

m3/h | I/s | |||||||

1.5/1B-AH | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

2/1.5B-AH | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

3/2C-AH | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

4/3C-AH | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

4/3D-AH | 60 | |||||||

6/4D-AH | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

6/4E-AH | 120 | |||||||

8/6E-AH | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

8/6R-AH | 300 | |||||||

10/8ST-AH | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 |

12/10ST-AH | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 |

14/12ST-AH | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 |

16/14TU-AH | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1065 |