Gravel Pumps

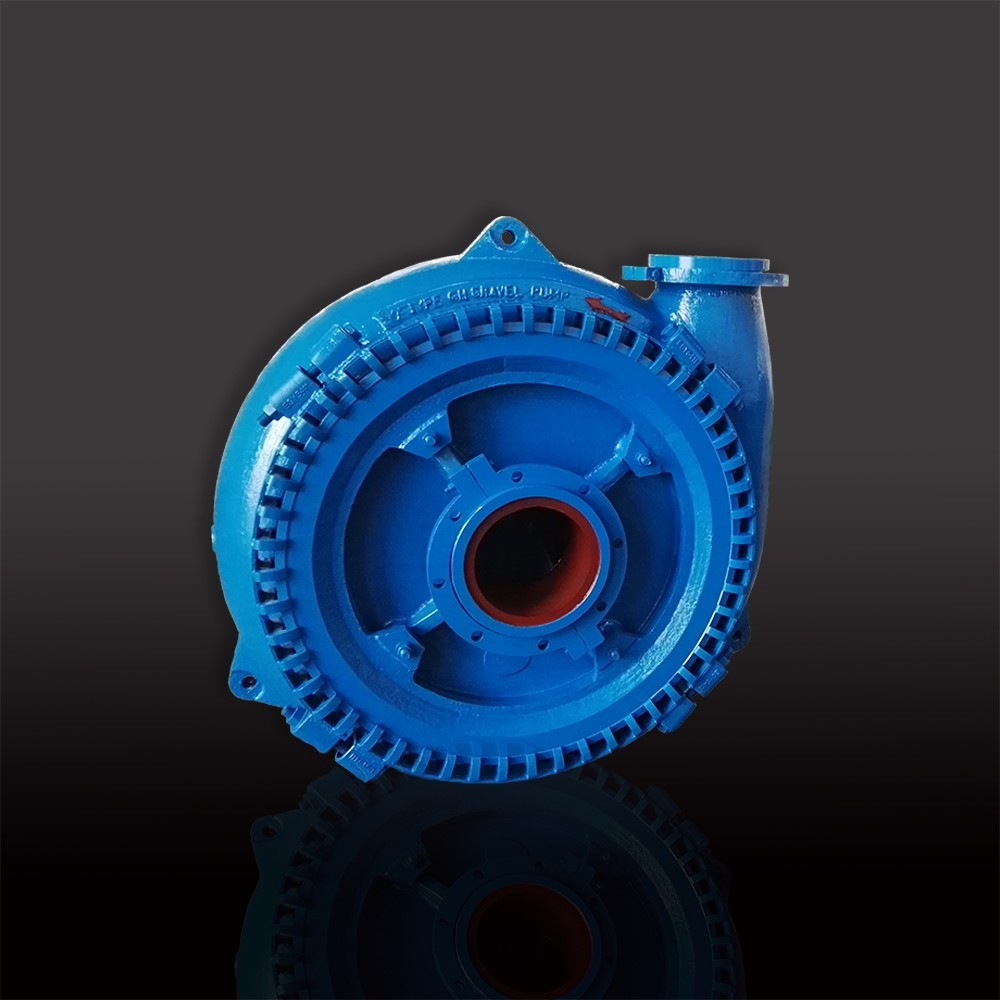

GTEK G series Gravel Pumps are designed to handle very large particles for gravel and dredge operations.

Description

GTEK G series Gravel Pumps are designed to handle very large particles for gravel and dredge operations. Capable of handling large particles at consistently high efficiencies result in low cost of ownership.The large volume internal profile of the casing reduces associated velocities further increasing component life. GTEK gravel and dredge pumps are designed to pump aggressive slurries with a wide distribution.

Applications:

Sand and Gravel

Hydraulic Mining

River Dredging

Cyclone Feed

Slag Granulation

Sugar Beet

Heavy Refuse Removal

Working Principle

Features

The unique segmented clamp ring allows casing rotation to any required angle, which removes the need for costly high wear bends.

IMPELLERS–Expulsion vanes cut down on gland pressure and reduces risk of high solid concentration in gland area.

CASING–Heavy duty casing has been designed to minimize internal velocities resulting in greater efficiency and prolonged wear life.

SEALS

EXPELLER (CENTRIFUGAL SEAL)–No gland water required

STUFFING BOX–flushed gland sealing with packing and lantern ring.

MECHANICAL SEALS

BEARING ASSEMBLY

–Grease lubricated cartridge bearing assembly,which is simple in structure,reliable in operation and easy to maintain.

–Large shaft diameters and reduced overhang in the wet end contribute to long life and reliability in the field.

- Safe and simple impeller adjustment to maintain top efficiency.

Model | Allowable Power (Kw) | Clean Water Performance | Impeller | ||||

Capacity Q(m3/h) | Head H(m) | Speed n(r/min) | Top Efficiencyη% | NPSH (m) | Impeller Diameter D (mm) | ||

6/4D-G | 60 | 36-250 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 |

8/6E-G | 120 | 126-576 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 |

10/8S-G | 560 | 216-936 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

10/8S-GH | 560 | 180-1440 | 24-80 | 500-950 | 72 | 2.5-5 | 711 |

12/10G-G | 600 | 360-1440 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

12/10G-GH | 600 | 288-2808 | 16-80 | 350-700 | 73 | 2-10 | 950 |

14/12G-G | 600 | 576-3024 | 8-70 | 300-700 | 68 | 2-8 | 864 |

16/14G-G | 600 | 720-3600 | 18-44 | 300-500 | 70 | 3-9 | 1016 |

16/14TU-GH | 1200 | 324-3600 | 26-70 | 300-500 | 72 | 3-6 | 1270 |

18/16TU-G | 1200 | 720-4320 | 12-48 | 250-500 | 72 | 3-6 | 1067 |