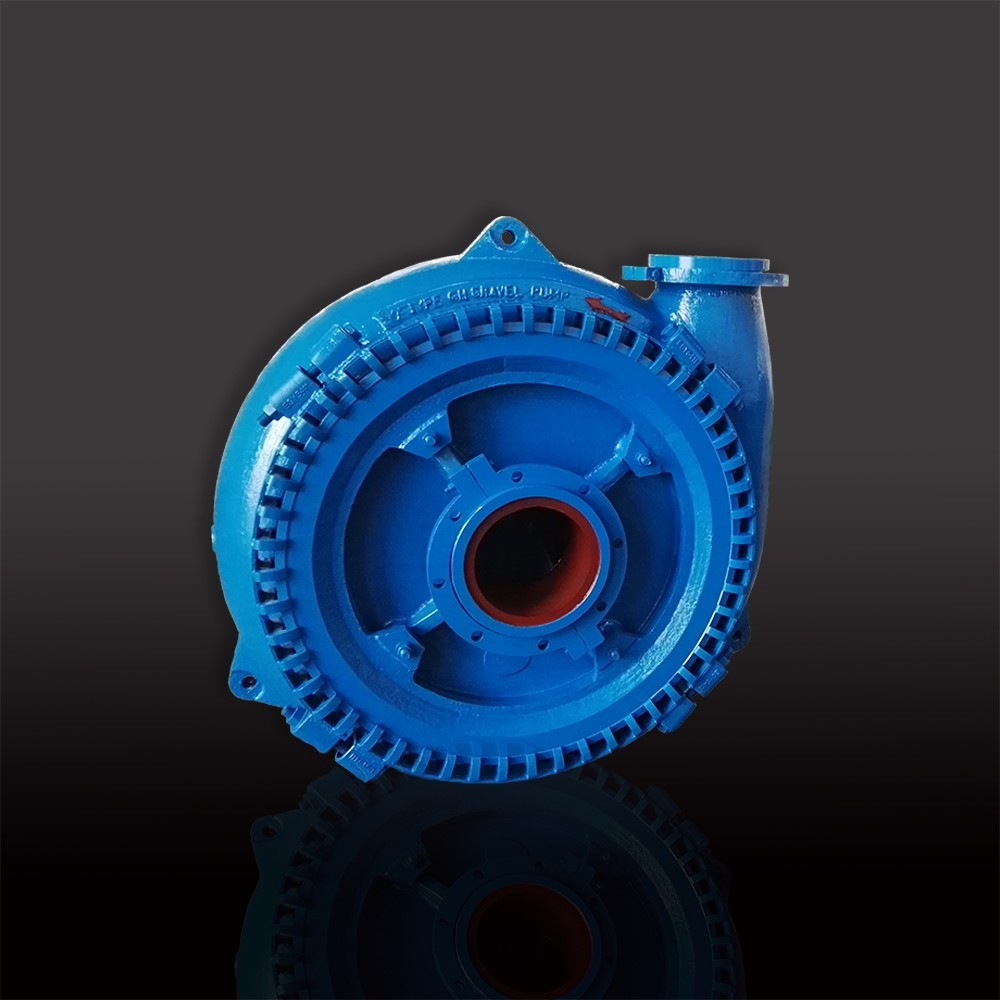

Corrosion Resistant Slurry Pump

GTEK UHB-ZK series corrosion-resistant and wear-resistant pumps can be used in transportation of various kinds of acid, alkali or other corrosive slurry and liquid. Its efficiency has been proven by our customers from all over the world.

Description

GTEK UHB-ZK series corrosion-resistant and wear-resistant pumps are single-stage single-suction cantilever centrifugal pumps, and the flow parts are steel-lined ultra-high molecular weight polyethylene (UHMWPE). This material is a new generation of anticorrosive and wear-resistant engineering plastic for pumps in the world. Its outstanding advantage is that it has excellent abrasion resistance and impact resistance (especially low temperature impact resistance) among all plastics. And it also features in creep resistance (resistance to environmental stress cracking) and good corrosion resistance.

The salient features of this pump are: multi-function, which means this model of pump can adapt to a variety of different working conditions, such as conveying acid, alkaline liquid or chemical slurry; various corrosive ore pulp in the smelting industry; various dilute acids in the sulfuric acid industry; Various types of sewage in the environmental protection industry. The UHB-ZK series pump is resistant to both corrosion and abrasion and has a wide range of uses.

Applications

1) Phosphate sulfate fertilizer industry: transportation of dilute acid, mother liquor, sewage, seawater, fluorosilicic acid containing silica gel, phosphoric acid slurry and other media.

2) Non-ferrous metal smelting industry: especially suitable for transportation of various acid solutions, corrosive pulp and slurry electrolytes for wet smelting of lead, zinc, gold, silver, copper, manganese, cobalt, and rare earth , Sewage and other media.

3) Chemical industry and other enterprises: transportation of various kinds of sulphuric acid, hydrochloric acid, alkaline, oil liquid or slurry. Is also suitable for production of titanium dioxide, iron red powder, various dyes and pigments, non-metallic mineral processing and other industries.

4) Chlor-alkali industry: hydrochloric acid, liquid alkali, electrolyte, etc.

5) Water treatment industry: pure water, high purity water, sewage (leather wastewater, electroplating wastewater, electronic wastewater, papermaking wastewater, textile wastewater, food industry wastewater, domestic wastewater, pharmaceutical wastewater, etc.).

6) Iron and steel enterprises: sulfuric acid and hydrochloric acid in pickling systems, and sewage with impurities.

7) Wet desulfurization circulating pump: It can be used for alkaline, acidic and corrosive material transportation at the same time.

8) Transportation of corrosive liquids and coal slurry in coal industry, coal chemical industry; Can be used as pumps for washing coal.

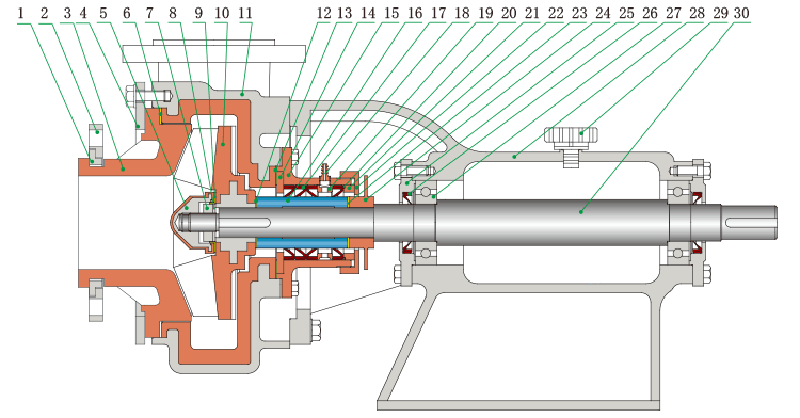

UHB-ZK series Corrosion-resistent Chemical Slurry Pump Structure

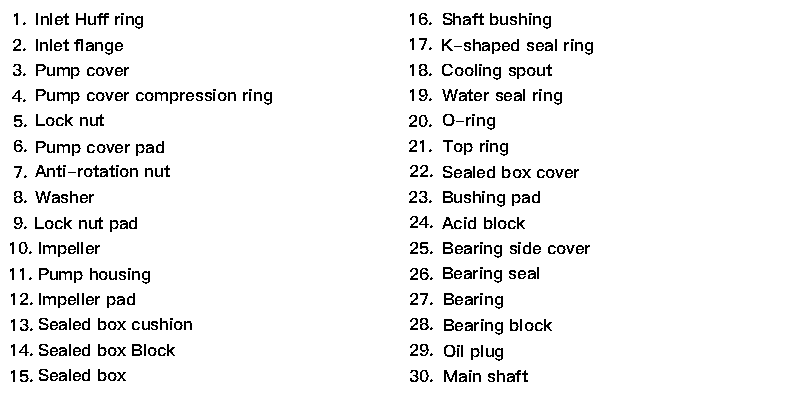

Performance Curves

We also provide different options of corrosion-resistant slurry pumps as below:

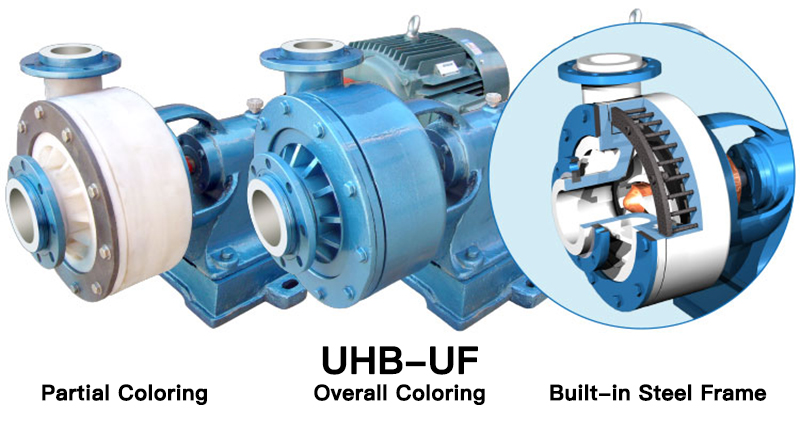

UHB-UF series full-plastic corrosion-resistant slurry pump

UF series' flow parts are made of modified ultra-high molecular weight polyethylene, and their use characteristics are corrosion resistance and wear resistance. Therefore, it is suitable for transporting corrosive and non-corrosive slurries or liquids within 90 ° C. Mainly suitable for conveying acid-base media, not suitable for conveying strong oxidizing acid and solvent media.

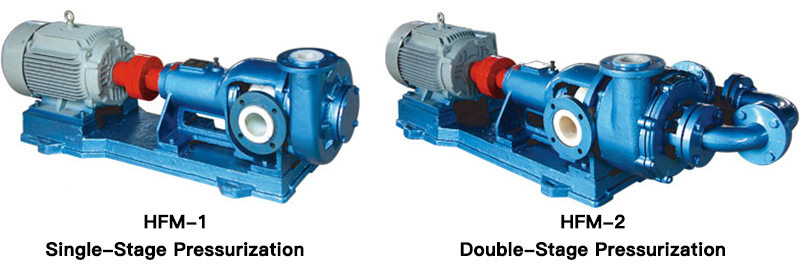

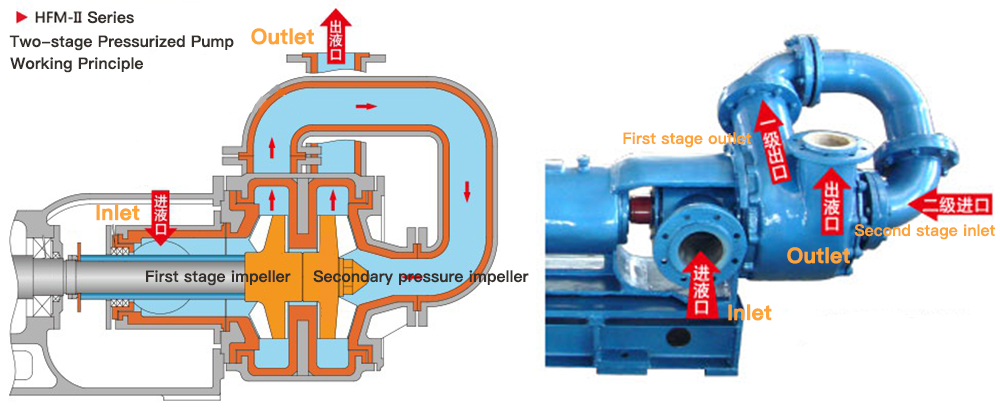

HFM Series Side-Suction Corrosion-Resistant Filter Press Pump

HFM Series are usually work with filter press or work in high pressure conditions. Due to the high pressure, HFM-II dual-stage corrosion-resistant and wear-resistant pump has good filtering effect when used with high-pressure filter press (low water content in the filter cake). It overcomes the shortcomings of insufficient pressure when using a common pump with a filter press.

GTEK Corrosion-resistant Pump

GTEK Pumps has gone through more than 30 years of development since we began producing corrosion-resistant and wear-resistant pumps. At present, the scale of the company's corrosion-resistant and wear-resistant pump products has developed to have more than 20 series and more than 2,000 specifications, which are available for users with different operating conditions and different needs. Based on professional service, high-quality product quality, and the "multi-variety, large-volume" business strategy, GTEK Pumps has won the recognition of more than 12,000 users.

Working Principle

The flow parts of UHB-ZK series pumps are steel-lined ultra-high molecular weight polyethylene (UHMWPE). This material is a new generation of anticorrosive and wear-resistant engineering plastic for pumps in the world. Its outstanding advantage is that it has excellent abrasion resistance and impact resistance (especially low temperature impact resistance) among all plastics.

Installation Diagram (when the liquid level is above the pump inlet)

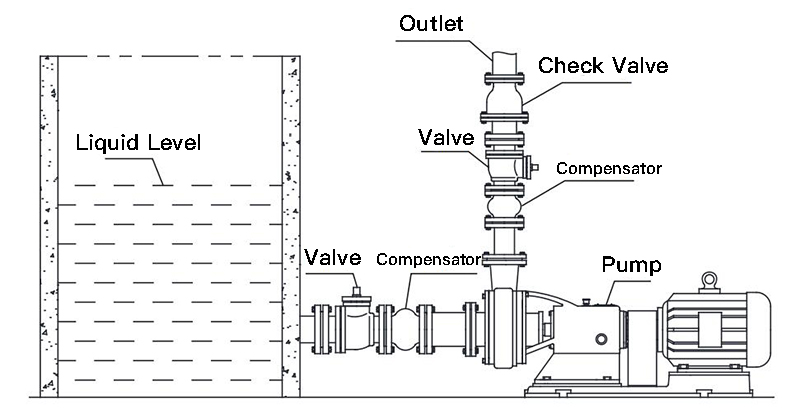

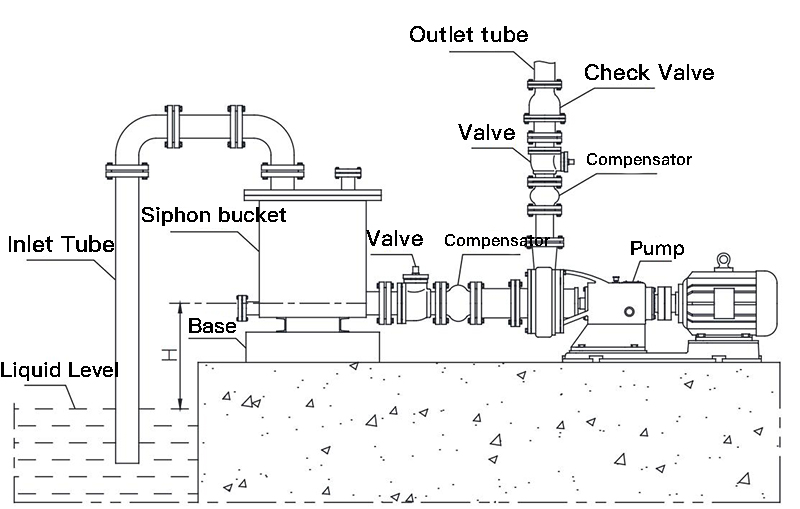

Installation Diagram (when the liquid level is below the pump inlet)

Features

Corrosion Resistent, can be used in various kinds of liquid, slurry of acid, alkali or other material.

Reliable Sealing Performance

Long Service Life

Extremely wide range of application

Below are specifications of some common UHB-ZK models, we can also provide various speical types for your requirements, such like: high head types, slow rotating speed types, etc. Please contact us for getting the most suitable type.

Model | Capacity (m³/hr) | Head (m) | Motor Power (kW) | Rotation Speed (r/min) | Inlet*Outlet Diameter (mm) | Dimension (mm) | ||

L6 | C | H1+H2 | ||||||

32UHB-ZK | 3~15 | 5~25 | 0.75~2.2 | 1450/2900 | 32*25 | 780/825 | 315 | 310/315 |

40UHB-ZK | 10~18 | 15~30 | 2.2~3 | 2900 | 40*32 | 845/900 | 315 | 330/335 |

50UHB-ZK | 10~30 | 7.5~43 | 1.1~7.5 | 1450/2900 | 50*40 | 960/1020/1060 | 380 | 390 |

65UHB-ZK | 15~40 | 8~32 | 1.5~7.5 | 1450/2900 | 65*50 | 1000/1060/1220 | 380/435 | 400/415 |

80UHB-ZK | 17.5~60 | 11~60 | 2.2~22 | 1450/2900 | 80*65 | 1010/1110/1200/1280/1320 | 380/435/555 | 430/445/505 |

100UHB-ZK | 50~120 | 11~58 | 5.5~37 | 1450/2900 | 100*80 | 1300/1400/1420/1440/1520 | 530/555 | 510/535 |

125UHB-ZK | 100~160 | 20~50 | 18.5~37 | 2900 | 125*100 | 1445/1485/1500/1560 | 530/555 | 490/515 |

150UHB-ZK | 80~300 | 8~40 | 11~45 | 980/1450 | 150*125 | 1800/1860/1900/1950/2000 | 580/700 | 840 |

200UHB-ZK | 168~500 | 10~45 | 18.5~75 | 980/1450 | 200*150 | 1915/2000/2075/2140 | 580/700/745 | 850/870 |

250UHB-ZK | 400~800 | 25~45 | 90~160 | 1450 | 250*200 | 2450/2480/2550/2580/2715/2850 | 850 | 1165 |

300UHB-ZK | 900~1400 | 20~30 | 110~185 | 980 | 300*250 | 2710/2730/2775/2825/3015 | 960 | 1325 |

350UHB-ZK | 1500~2000 | 20~35 | 185~280 | 980 | 350*300 | 3390/3620/3690 | 1080 | 1550 |

400UHB-ZK | 2000~2500 | 20~30 | 250~355 | 980 | 400*350 | 3920/4380 | 1070 | 1335/1435 |

500UHB-ZK | 2500~3000 | 20~35 | 280~450 | 980 | 500*450 | 5655 | 1380 | 1745 |

600UHB-ZK | 4000~5800 | 20~30 | 560~710 | 740 | 600*500 | 5700/6000 | 1480 | 2010 |