Peristaltic Hose Pump

GTEK RGB series hose pumps (aka peristaltic hose pumps) work by squeezing hoses with rollers or sliders. It is widely used in metallurgy, rare earth, desulfurization and environmental protection, water treatment, papermaking, paint, Titanium dioxide, compound fertilizer and other industries.

Description

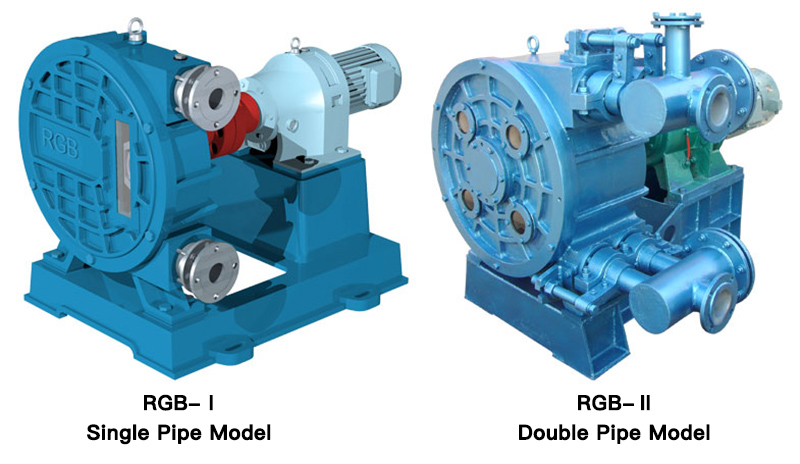

GTEK RGB series hose pumps (aka peristaltic hose pumps) work by squeezing hoses with rollers or sliders. The pump can run idling, self-priming, and handle high-viscosity, high-wear media. The pump body does not need to be sealed, there is no leakage, and it can output a fixed flow rate each time it rotates. It has the characteristics of low speed and no noise. It is widely used in metallurgy, rare earth, desulfurization and environmental protection, water treatment, papermaking, paint, Titanium dioxide, compound fertilizer and other industries. This series of pumps are available in single and double tube models.

Applications:

This pump is especially suitable for corrosive media with high solid content and high viscosity, and has excellent self-priming performance.

It is widely used in smelting (gold, silver, copper, lead, zinc, tin, nickel, cobalt, manganese), phosphorus compound fertilizer, titanium white, citric acid, rare earth, rare metals, inorganic salts, desulfurization and environmental protection, water treatment, papermaking, paint, etc industries. The specific applications are as follows:

A. Drilling mud and transportation of organic solvents and fuel oils such as crude oil and gasoline, kerosene in the petroleum industry;

B. Acid, alkali, salt and phosphoric acid slurry, titanium dioxide slurry and calcium citrate, etc. in chemical industry; crystal liquid, suspension, latex, resin, slime and various liquid materials;

C. Slurry transportation and rare metal liquid transportation in the smelting industry;

D. Drug delivery in the pharmaceutical industry;

E. Transportation of mud, lime slurry, and impurities in the water treatment and desulfurization industries;

F. Transportation of cement mortar for the construction industry;

G. Material handling in the food industry;

H. Pulp and sulfur pulp transportation in the paper industry;

I. Conveying of ceramic glaze in the ceramic industry;

J. Conveyance of poorly flowing materials such as paints, coatings, latex in the paint industry;

K. Toothpaste, cream, shampoo, conditioner, cream, face oil, etc. in the cosmetics industry;

L. Yeast, diatomaceous earth, wine tank, syrup, ingredients, concentrated liquid, gas-liquid mixture in beer industry.

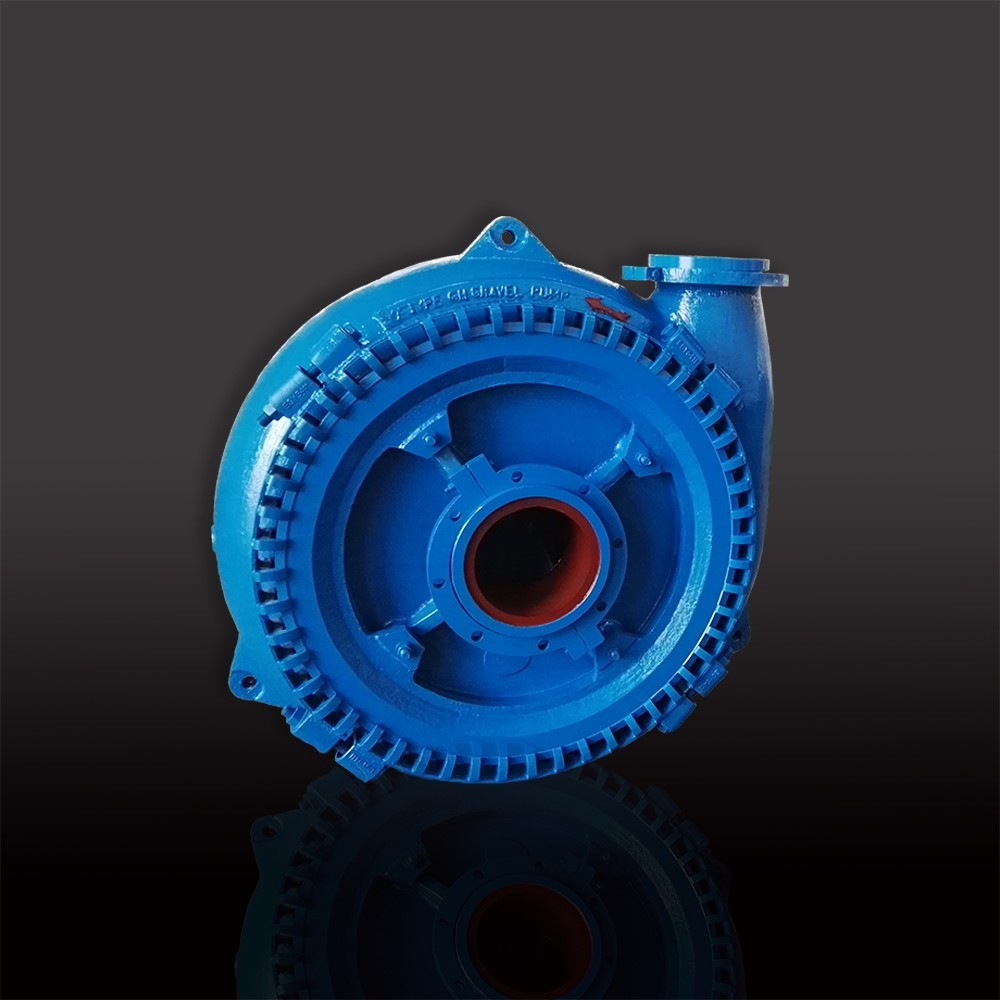

GTEK Corrosion-resistant Pump

GTEK Pumps has gone through more than 30 years of development since we began producing corrosion-resistant and wear-resistant pumps. At present, the scale of the company's corrosion-resistant and wear-resistant pump products has developed to have more than 20 series and more than 2,000 specifications, which are available for users with different operating conditions and different needs. Based on professional service, high-quality product quality, and the "multi-variety, large-volume" business strategy, GTEK Pumps has won the recognition of more than 12,000 users.

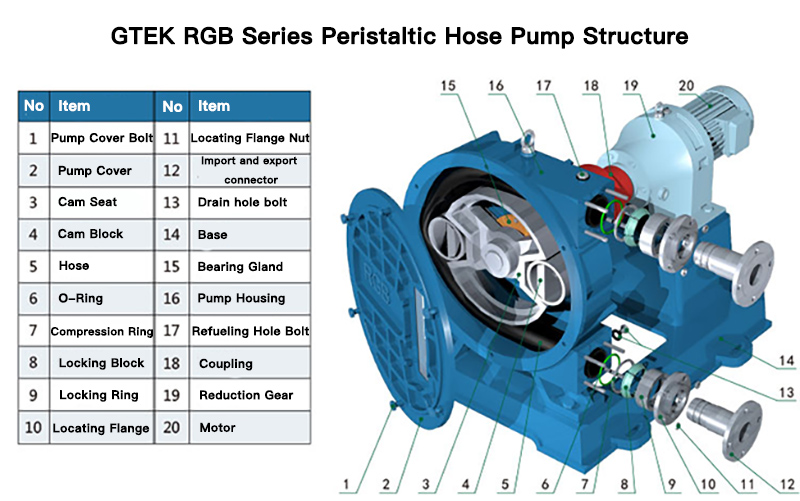

Working Principle

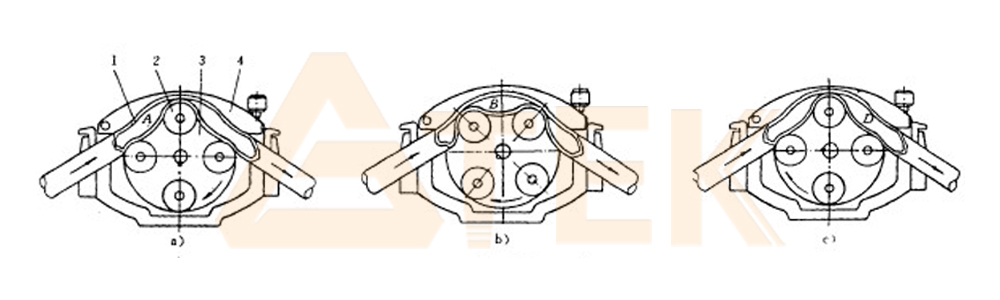

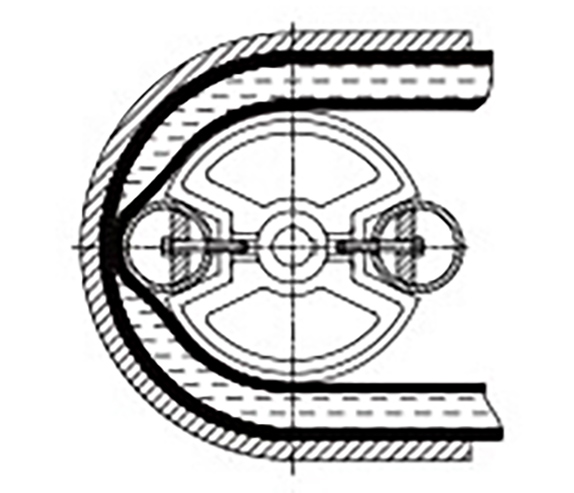

Peristaltic Hose Pump consists of a hose (1), a roller (2) mounted on a rotor (3), and the pump housing (4). When the rotor is rotated, the inner cavity A of the hose formed by the pinch between the roller and the pump housing gradually increases from the generation, and this cavity is in a state of liquid absorption. When the rotor is turned to the position in Figure b, the liquid that has entered the A cavity is squeezed by the roller to the closed cavity B. At the position in Figure c, this part of the liquid is squeezed out to the D cavity that connect to the pump outlet pipe, and then is discharged from the pump outer. The continuous rotation of the rotor forms a continuous "creeping" of the hose, which continuously transports liquid from the low-pressure inlet of the pump to the high-pressure outlet.

The number of rollers for peristaltic hose pump can also be two, three or more. On some pumps, the rollers are replaced by low-friction extrusion elements with special leading and trailing edge shapes. The below figure is a simplified diagram of a peristaltic pump with two pulleys instead of rollers.

Features

1. Strong self-priming ability, the suction distance of fresh water can reach 8m;

2. The structure is unique, and no seal is used, so no leakage will occur;

3. Able to transport corrosive slurry, sludge, etc. containing a large amount of particles, fibers or other impurities;

4. The medium has low flow velocity and no shear force, which is especially suitable for conveying materials sensitive to shear force;

5. Can transport high-viscosity media, and can also transport gas, liquid, solid mixed media;

6. By adjusting the speed of the pump, the flow can be adjusted, while the outlet pressure of the pump is basically unchanged;

7. When the speed is constant, adjusting the outlet valve can change the outlet pressure of the pump while the flow rate is basically unchanged. Therefore, the pump has a certain metering function and can be used as a metering pump;

8. Optional hose materials, suitable for different media. (Please ask us for the corrosion parameter table of the hose material)

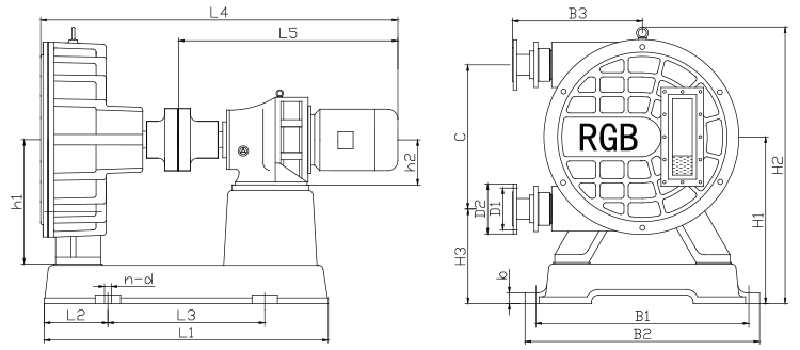

Model | Max. Capacity (m³/h) | Rated Discharge Pressure (kg/cm²) | Rated Rotation Speed (r/min) | Hose Internal Diameter (mm) | Clear Water Suction (m) | Motor Power (kW) | Max. Solid Diameter (mm) | Dimension (mm) | |||

L4 | B2 | H2 | |||||||||

50RGB | -3.5-6 | 3.5 | 6 | 35 | 51 | 8 | 3 | 10 | 1368 | 410 | 835 |

-6-6 | 6 | 63 | |||||||||

65RGB | -8.5-6 | 8.5 | 35 | 64 | 8 | 7.5 | 12 | 1280 | 410 | 935 | |

-13-6 | 13 | 63 | |||||||||

65RGB-Ⅱ | -17-6 | 17 | 35 | 64 | 8 | 11 | 12 | 1576 | 630 | 955 | |

-25-6 | 25 | 63 | 15 | ||||||||

80RGB | -13-6 | 13 | 35 | 76 | 8 | 11 | 15 | 1595 | 540 | 1100 | |

-24-6 | 24 | 63 | |||||||||

80RGB-Ⅱ | -27-6 | 27 | 35 | 76 | 8 | 15 | 15 | 1755 | 730 | 1090 | |

-48-6 | 48 | 63 | 18.5 | ||||||||

100RGB | -25-6 | 25 | 35 | 102 | 8 | 15 | 15 | 1898 | 1140 | 1485 | |

-45-6 | 45 | 63 | 18.5 | ||||||||

100RGB-Ⅱ | -50-6 | 50 | 35 | 102 | 8 | 18.5 | 15 | 2007 | 1100 | 1458 | |

-90-6 | 90 | 63 | 22 | ||||||||