Mineral Jig

Mineral jig is a type of mining equipment, also referred to as gravity concentrators or jig concentrator. Mineral jig concentrator can be used in operations to separate minerals with significant differences in specific gravity.

Description

Mineral jig is a type of mining equipment, also referred to as gravity concentrators or jig concentrator. Mineral jig concentrator can be used in operations to separate minerals with significant differences in specific gravity. GTEK design and manufacture high quality KXT mineral jig concentrator with the latest technology. Our KXT mineral jig has been widely used in recovering valuable heavy materials such as gold, platinum, tin, tungsten and lower density minerals, gemstones such as diamond and sapphire from alluvial or placer deposits. Our mineral jig has also been widely used in hard rock gold applications for recovering of coarse gold liberated in open or closed grinding circuits.

Proved by our end-user worldwide, the recovery rate of placer gold can be above 95%. When the jig is used in hard rock mining for recovery of gold coarser than 0.074mm, the recovery rate can reach up to 90% and ratio of enrichment can reach 30 to 300 times.

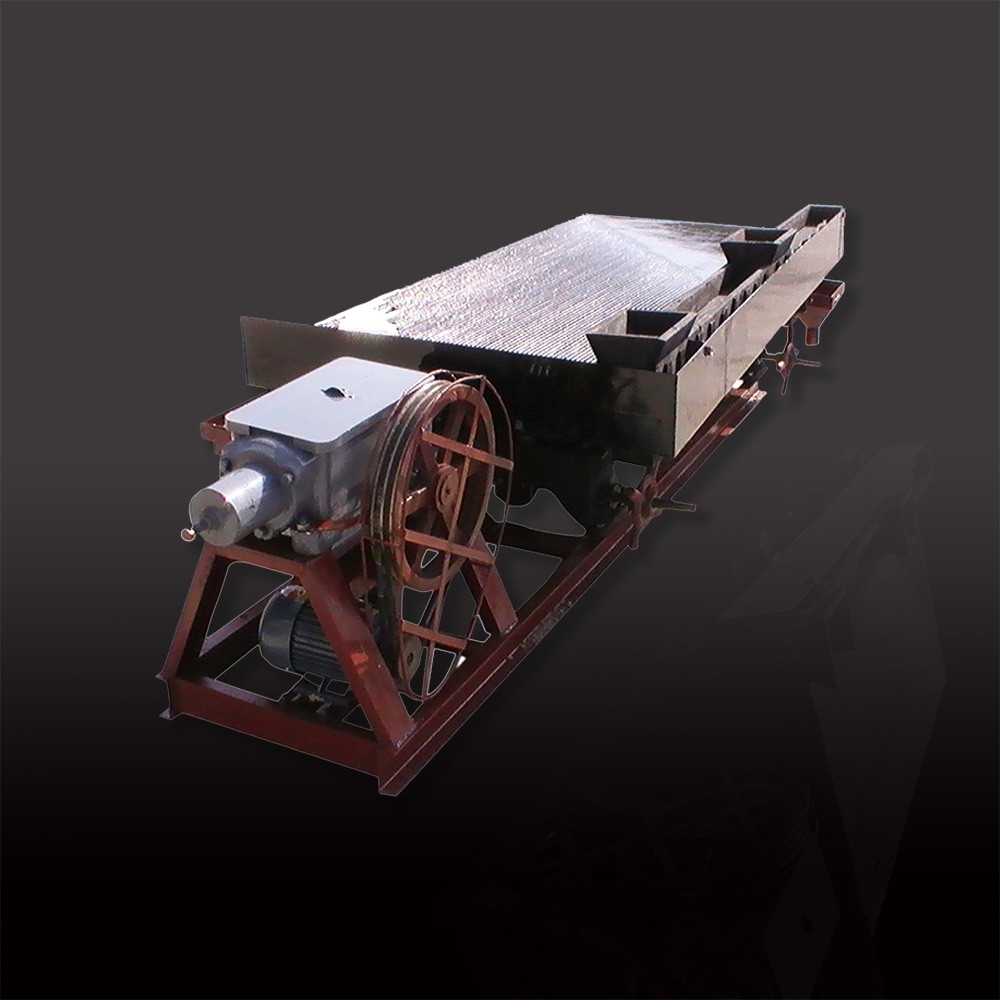

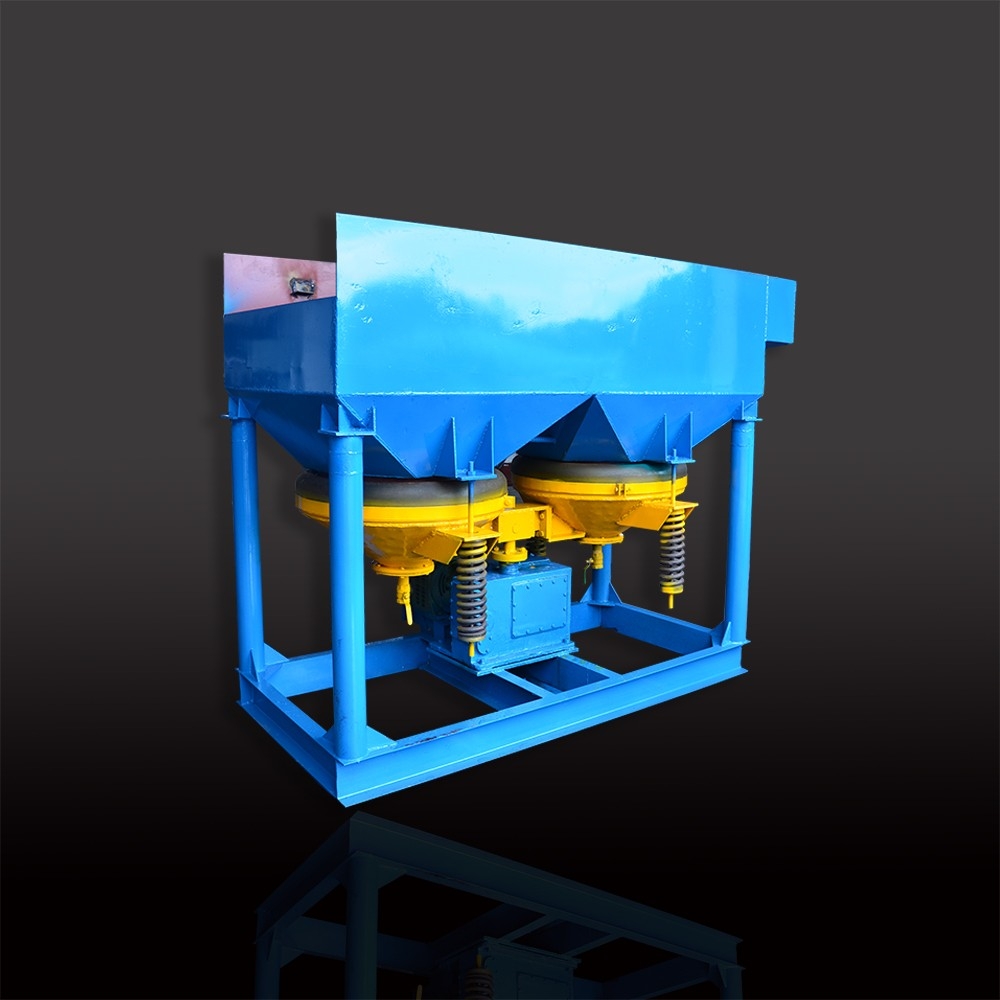

KXT Mineral Jigs

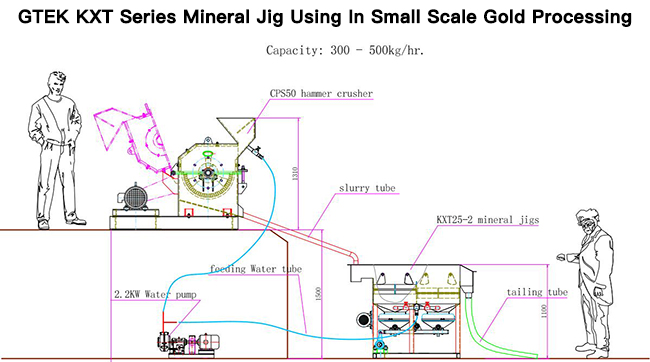

Small Scale Gold Processing

Working Principle

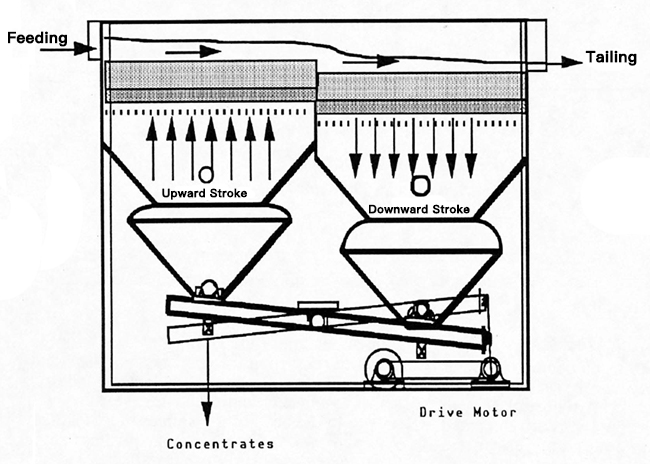

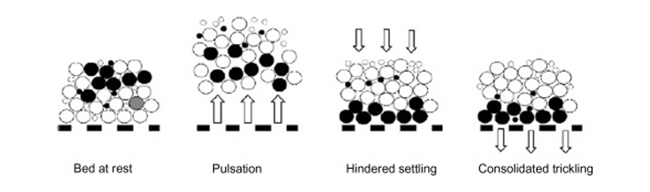

The KXT mineral jig consists of a cell containing water with a perforated horizontal screen on the top. Steel shot or stainless steel shot or a thick bed of coarse particles is placed on the screen. A rubber diaphragm located at the bottom of the cell is driven up and down by a walking beam and eccentric mechanism. Water is pulsated up and down by eccentric-driven diaphragm.

On the upward stroke of diaphragm mechanism, a pulsating current of water dilates the jig bed so that heavy particles move to the bottom and light particles to the top of the bed. On the downward stroke of diaphragm mechanism, heavier particles are pulled down through the bed and discharge through the hutch concentrate valve at the bottom. While the light particles are carried away by crossflow supplemented by a large amount of water continuously supplied to the concentrate hutch to enter the next jig cell or to be discharged as tailing.

Feed rate, depth of bed, pulsation frequency, stroke length, and make-up are main variables to adjust the jig for optimum recovery.

Features

1. High recovery rate of gold. The jig can improve recovery rate of gold from 5% to 40%. It also can recovery the gold as fine as 270 meshes;

2. Improve production efficiency.The jig can continuously discharge the concentrate when operating and there is no need to stop the machine for collection of concentrate;

3. Strong adaptability: The jig is not only used for placer and rock gold mines, but it can also be used for recovery of heavy minerals such as iron, tin and tungsten ore;

4. Simple operation and easy maintenance. As the machine has few moving parts,it is very reliable in operation.

Model | Quantity Of Cells | Capacity (Dry Ore) (t/hr) | Hutch Water (m³/hr) | Feed Density (%) | Feed Size (mm) | Motor Power (kW) | Dimension | Weight (Kg) |

L*W*H (mm) | ||||||||

KXT-25 | 1 | 1.5~3 | 0.7~1.5 | 0~40 | <6 | 0.55 | 1100*600*1200 | 190 |

KXT-50 | 1 | 5~10 | 2~6 | 0~40 | <8 | 1.1 | 1500*800*1450 | 370 |

KXT-100 | 1 | 10~20 | 4~8 | 0~40 | <20 | 2.2 | 2000*1100*1620 | 920 |

KXT2-25 | 2 | 2~4 | 2~4 | 0~40 | <8 | 0.75 | 1510*590*1100 | 326 |

KXT2-50 | 2 | 5~10 | 6~12 | 0~40 | <10 | 1.5 | 2100*760*1565 | 750 |

KXT2-100 | 2 | 15~30 | 10~25 | 0~40 | <20 | 2.2 | 3150*1300*1770 | 1250 |