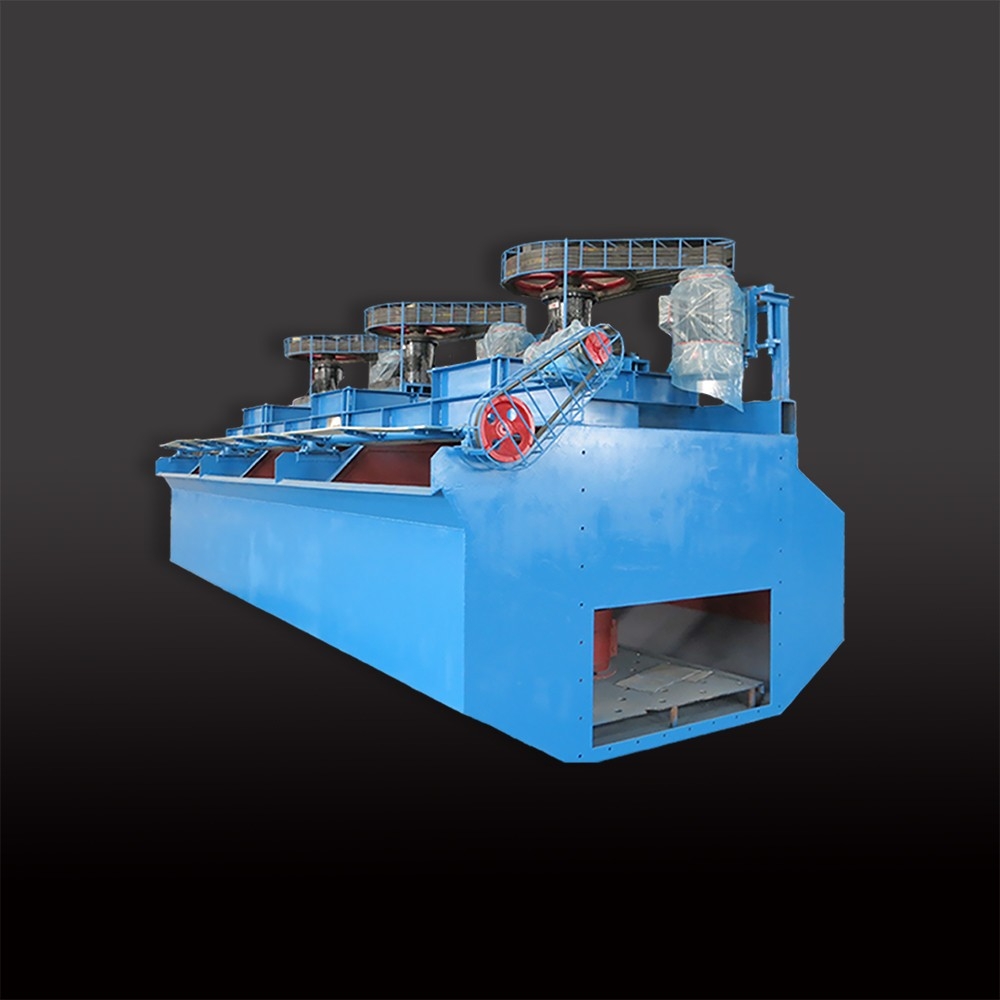

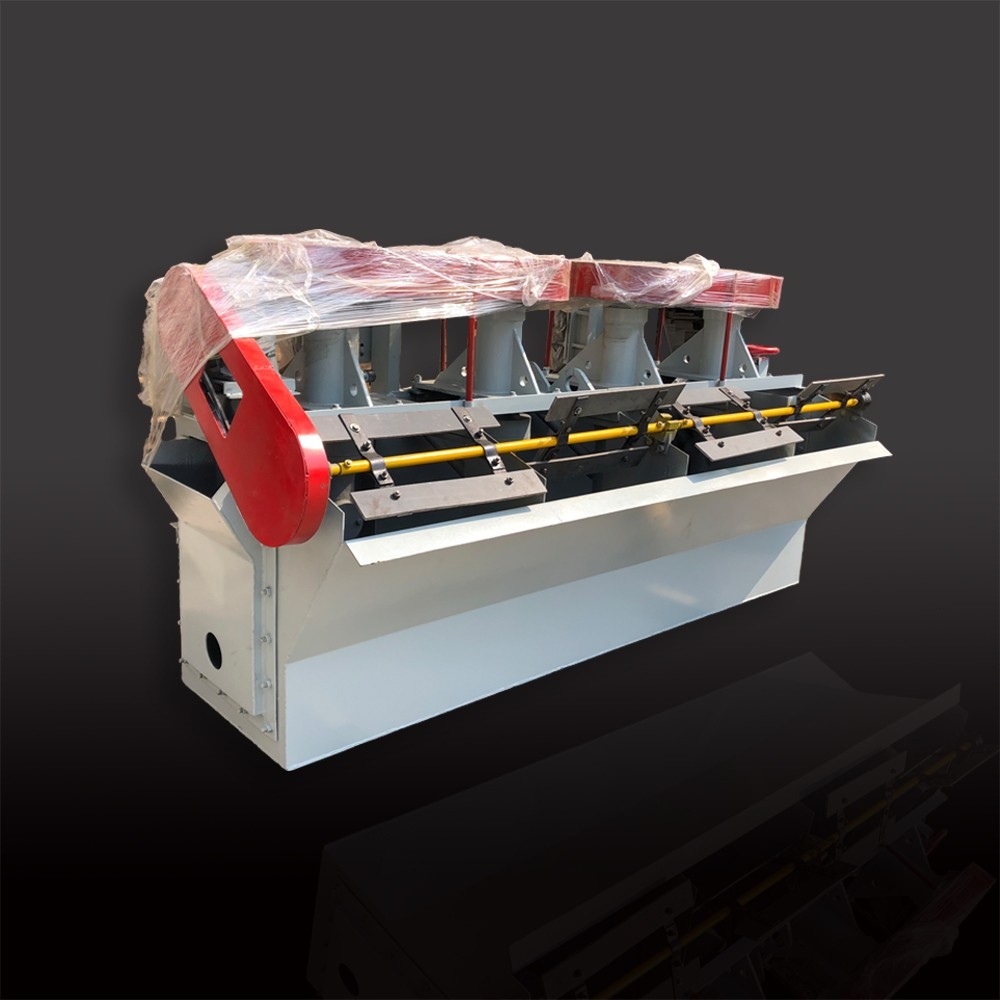

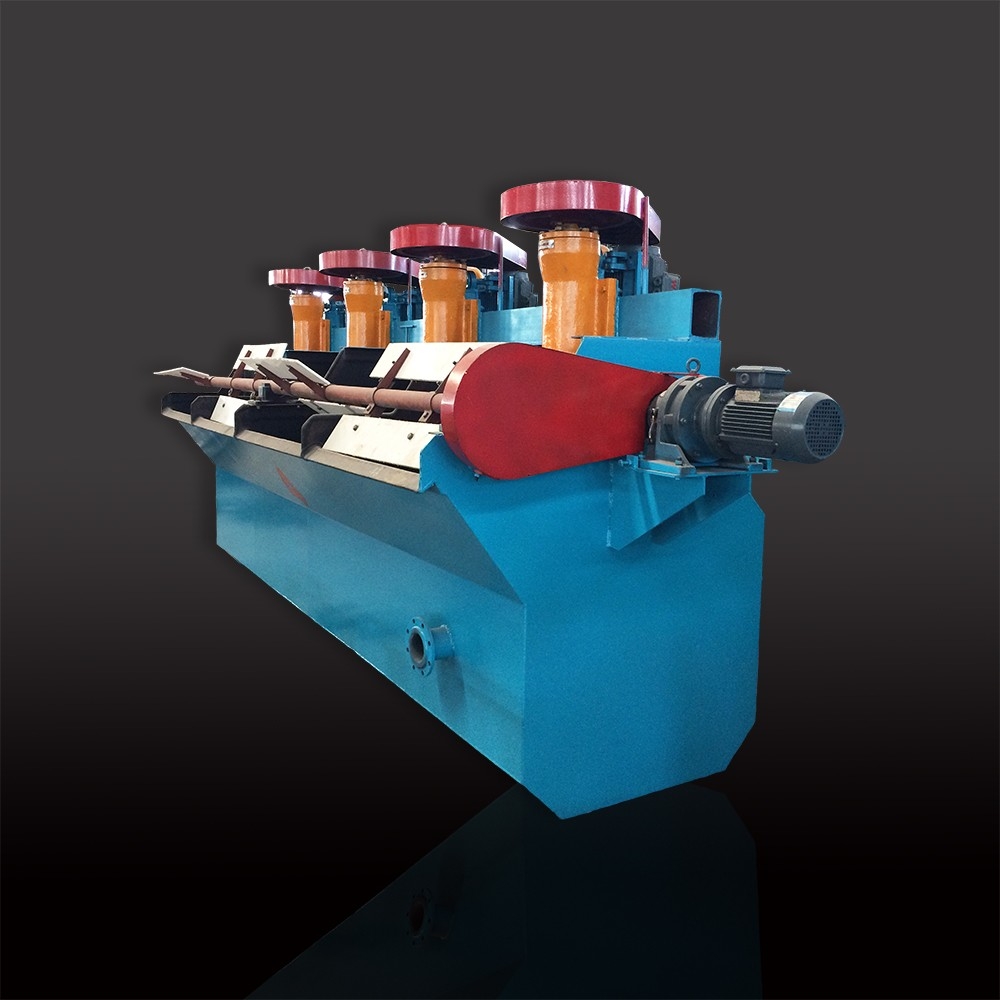

JJF Flotation Machine

GTEK JJF flotation cell can be rougher and scavenging flotation application for nonferrous metal, ferrous metal and non-metallic minerals.

Description

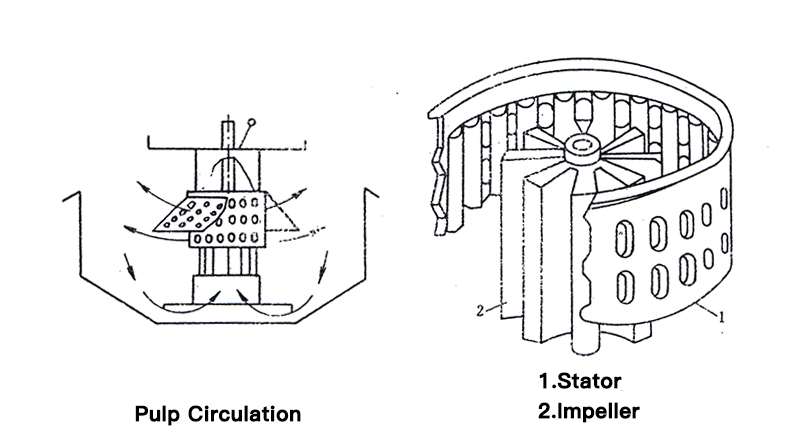

GTEK JJF flotation cell is an open-trough type, self-aerating mechanical flotation cell.

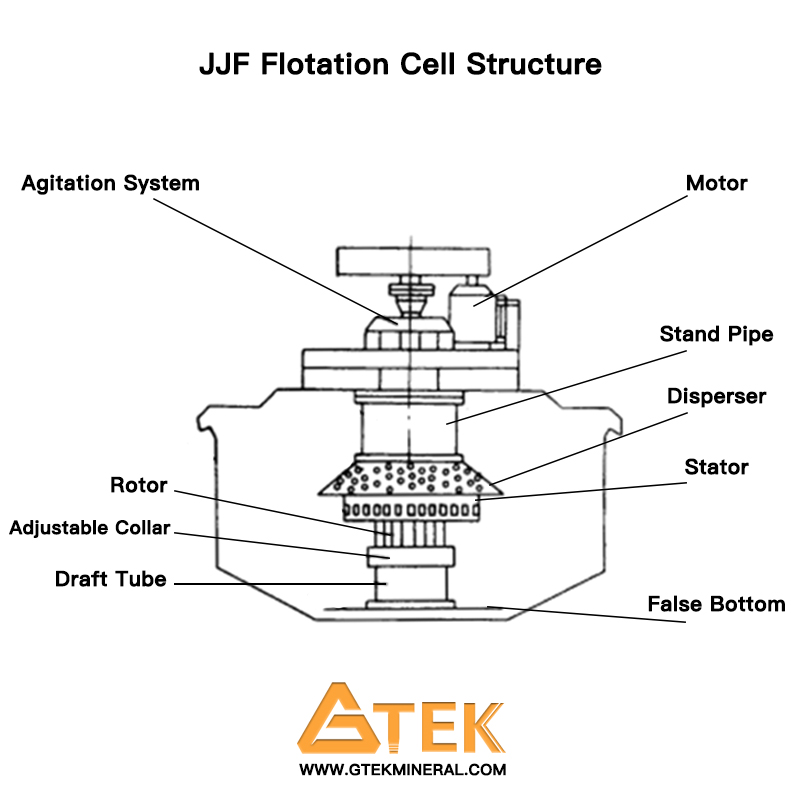

The large capacity JJF flotation cells have a false-bottom with draft tube system which enhances the circulation of the pulp.It permits a low rotor submergence, even for the large capacity cells.

GTEK JJF flotation cell can be rougher and scavenging flotation application for nonferrous metal, ferrous metal and non-metallic minerals.

JJF Flotation Machine is usually used combined with the SF Series Flotation Machine to compose a Flotation Group as a Primary Separation device.

Working Principle

When operating, the rotor creates a fluid vortex inside the stand pipe and the draft tube, and cause a sufficient vacuum area to induce air into the stand pipe through the air inlet duct. The induced air is mixed with pulp between the impeller and stator. The mixture of air and pulp will have a tangential movement as a result of the impeller. But when the Mineralized Bubbles pass through the pores on the stator, they change to a radial motion until they bump into the Disperser and be separated evenly. When the Mineralized Bubbles rise up to the froth zone, the scraper revolve to discharge the products.

Features

1.Low power consumption due to small diameter and low speed of rotor;

2.Large design clearance between the rotor and disperser resulting minimal wear;

3.Good circulating of pulp and mixing of pulp with air;

4.The conical stator hood is to quieten the cell surface and to keep any turbulence created by the rotor away from the froth layer;

5.A false bottom and draft tube channel slurry flow,ensuring high re-circulation and eliminating sanding;

6.self-aerating flotation cell,no blower and associated air piping is required;

7.The rotor is well above the tank bottom,eliminating contact with abrasive,oversized tramp material;

8.Shorter froth travel distance for improved coarse particle recovery;

9.A beveled tank bottom for coarse particle suspension.

Model | Impeller Diameter (mm) | Capacity (m3/min) | Impeller Speed (m/s) | Motor Power(KW) | Dimensions (L*W*H) (mm) |

JJF-20 | 700 | 5-20 | 6.6 | 37 | 2850*3800*2000 |

JJF-10 | 540 | 4-12 | 6.6 | 22 | 2200*2900*1700 |

JJF-5 | 410 | 2-6 | 5.55 | 13 | 1600*2150*1550 |

JJF-16 | 700 | 5-6 | 6.6 | 37 | 2850*3800*1700 |

JJF-8 | 540 | 4-10 | 6.6 | 22 | 2200*2900*1400 |

JJF-4 | 410 | 2-5 | 6.6 | 11 | 1600*2150*1250 |

JJF-3 | 350 | 1-3 | 6.6 | 11 | 1500*1850*1200 |

JJF-2 | 280 | 0.5-2 | 6.5 | 7.5 | 1400*1400*1150 |

JJF-1 | 280 | 0.3-1 | 6.5 | 5.5 | 1100*1100*1000 |