Jar Mill

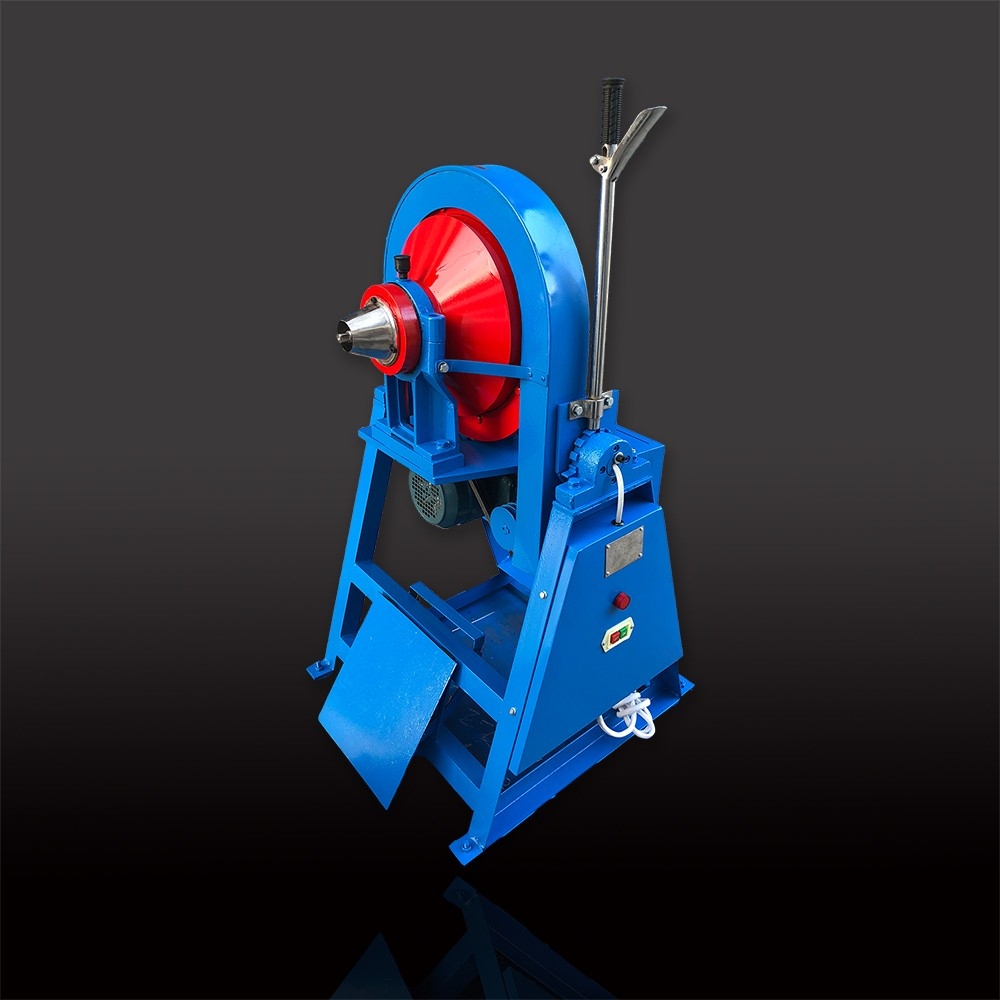

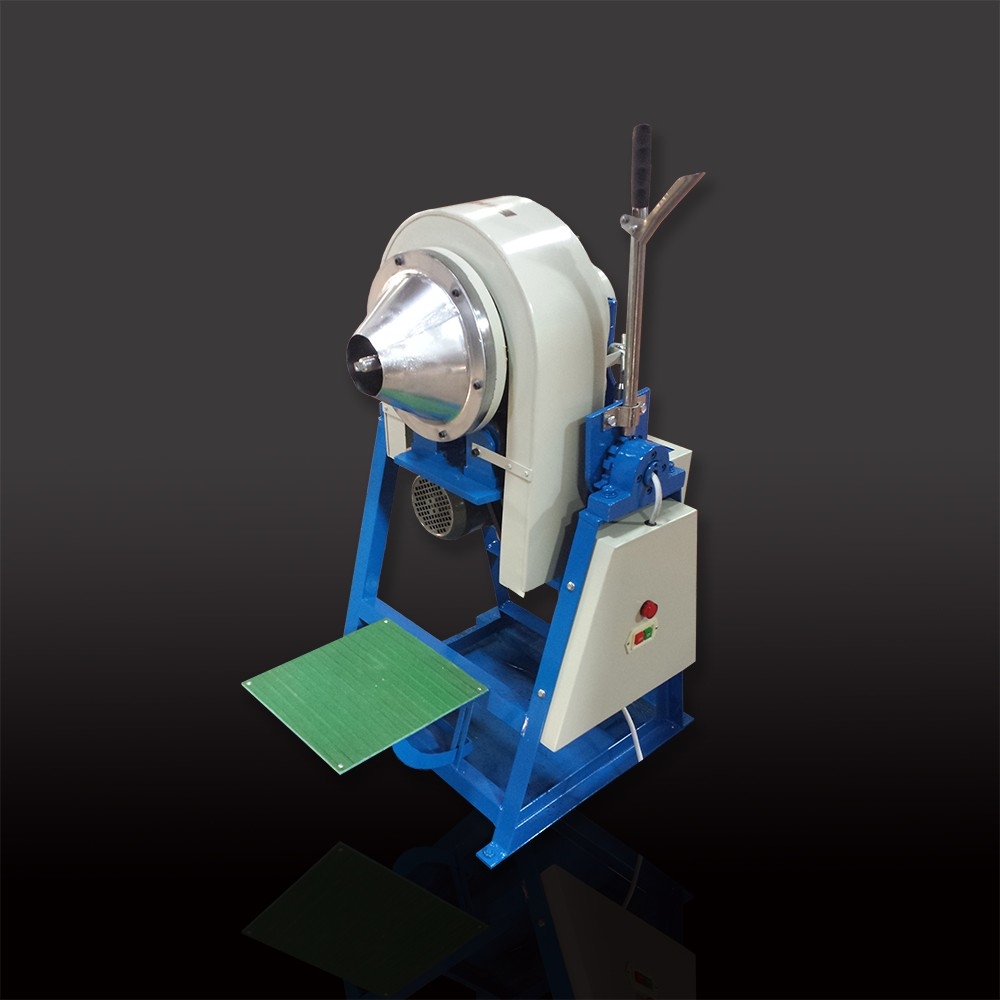

GTEK bench or floor type Jar Mills are ideal for wet or dry grinding, blending, dispersing and other conditioning in the laboratory.

Description

GTEK bench or floor type Jar Mills are ideal for wet or dry grinding, blending, dispersing, and other conditioning in the laboratory.

·Jar Mill, 1 Tier is a floor style Jar Mill that accommodates four jars. Maximum feed capacity is 30L.

·Jar Mill, 2 Tier floors type accommodates four jars each tier. Maximum feed capacity is 20L.

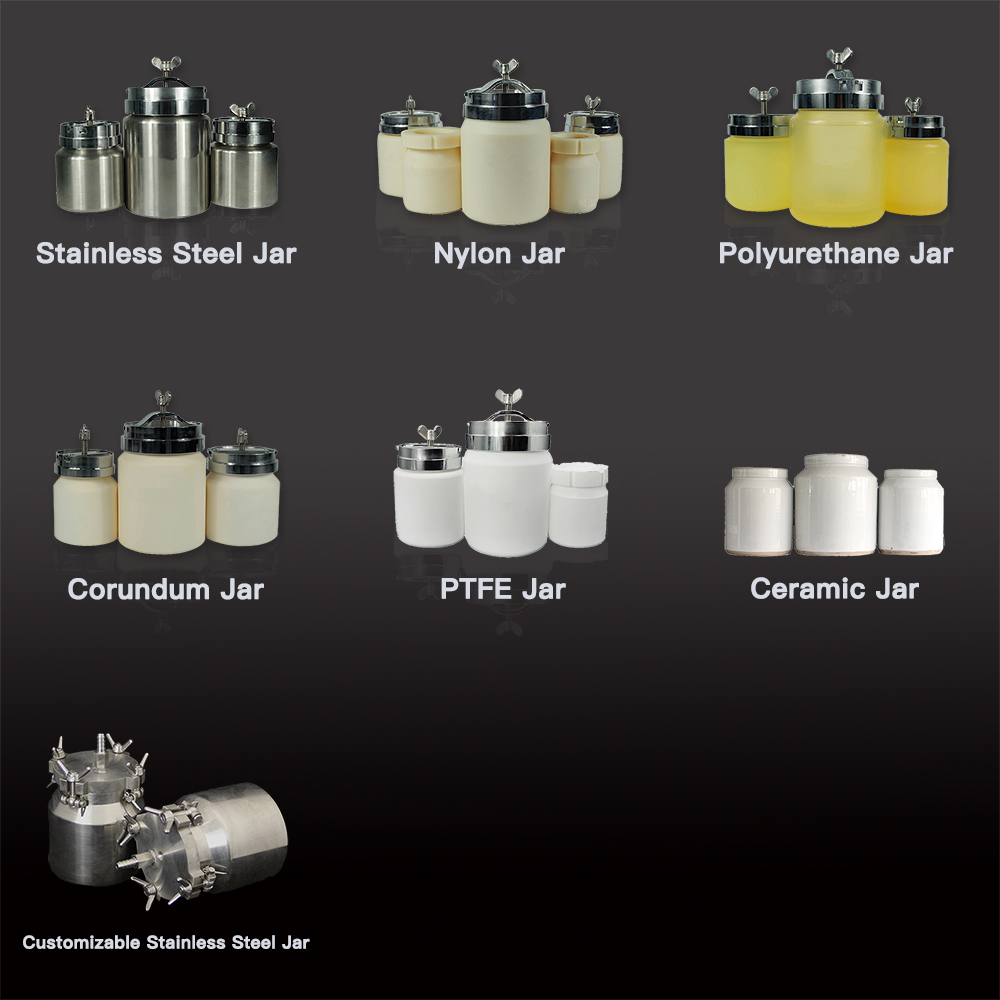

Grinding Jars are available in six types of materials as below

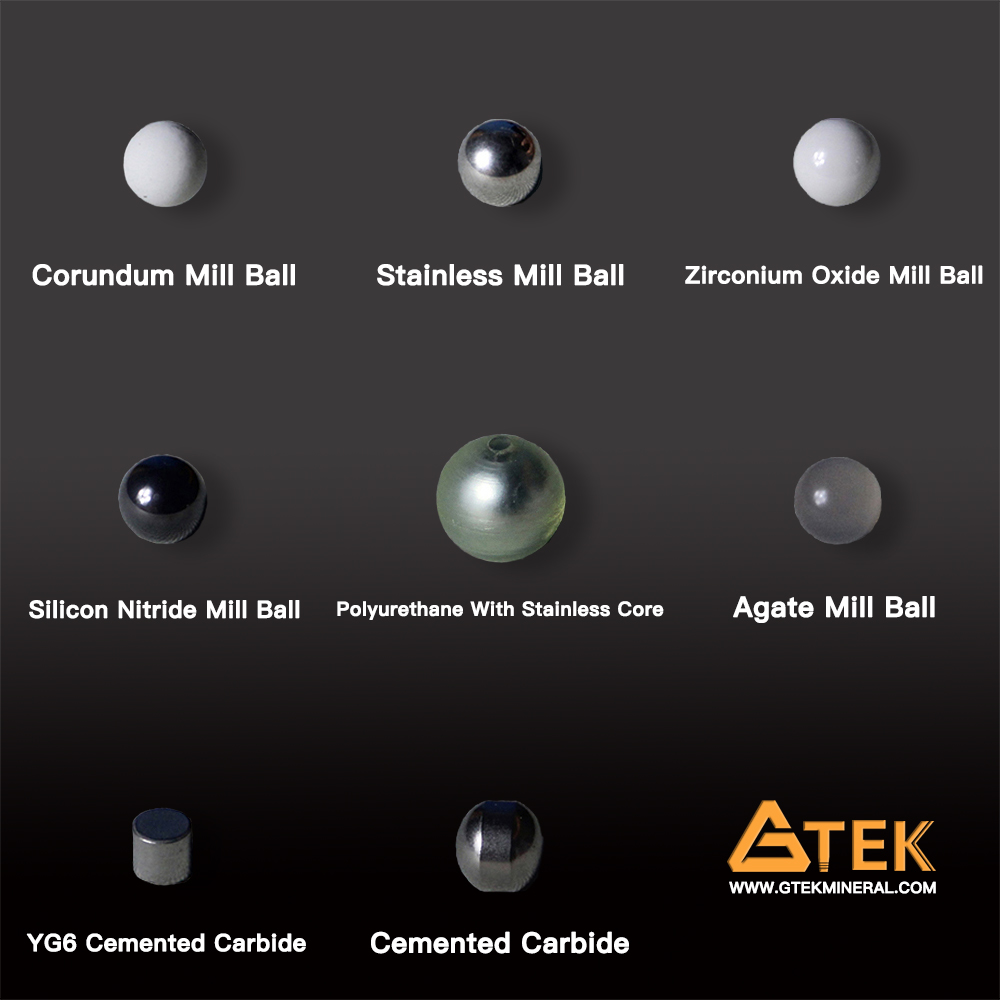

Grinding Media is available in your selection of either stainless steel, corundum, high alumina, polyurethane with steel core, agate.

Mills operate on 115V, 50/60Hz or 230V/50Hz electrical supply. Grinding Jars and Grinding Media are required for using with this equipment and are ordered separately.

We can also customize a laboratory jar mill based on special customer requirements.

Working Principle

The motor drive special polyurethane-covered rollers at speeds from 0 to 300rpm. Roller spacing adjusts easily to accommodate jars of different size and are configured to keep jars centered during operation. The roller speed is regulated from 0 to 300rpm by VFD.

Features

1. Control speed 0-300rpm regulated by VFD;

2. Quiet and smooth operation with lower power consumption;

3. Roller spacing adjusts easily to accommodate jars of different size

4. Stainless roller lined with polyurethane to improve frictional coefficient to prevent jars from over running the roll.

Model | Adaptive Jar | Tiers | Roller shafts | Available jar diameter(mm) | RPM | Voltage (V) | Working power (KW) | Dimensions | Transmission mode | ||||

Volume | Quantity | Quantity (per tier) | Diameter | Length | Adjustable spacing | (L*W*H/ mm) | |||||||

GMS1-2 | 0.5-1L | 2 | 1 | 2 | φ40 | 180 | 52~160 | φ50-φ160 | 0~300 | 220V | 0.75 | 580*420*410 | Belt |

GMS3-2 | 0.5-3L | 2 | 1 | 2 | φ50 | 220 | 52~210 | φ50-φ200 | 0~300 | 220V | 0.75 | 660*440*410 | Belt |

GMS5-1 | 0.5-5L | 1 | 1 | 2 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 0.75 | 500*350*320 | Belt |

GMS5-2 | 0.5-5L | 2 | 1 | 2 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 0.75 | 760*610*530 | Belt |

GMS10-2 | 0.5-10L | 2 | 1 | 2 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 220V | 1.5 | 790*630*530 | Synchronous belt |

GMS20-2 | 0.5-20L | 2 | 1 | 2 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 2.2 | 827*952*724 | Synchronous belt |

GMS30-2 | 1-30L | 2 | 1 | 2 | φ80 | 425 | 35~290 | φ60-φ360 | 0~200 | 380V | 2.2 | 1328*658*720 | Synchronous belt |

GMS1-4 | 0.5-1L | 4 | 1 | 3 | φ40 | 180 | 62~160 | φ50-φ160 | 0~300 | 220V | 0.75 | 580*520*410 | Belt |

GMS3-4 | 0.5-3L | 4 | 1 | 3 | φ50 | 230 | 76~230 | φ70-φ180 | 0~270 | 220V | 0.75 | 780*648*530 | Belt |

GMS5-4 | 0.5-5L | 4 | 1 | 3 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 1.5 | 850*748*530 | Belt |

GMS10-4 | 0.5-10L | 4 | 1 | 3 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 380V | 2.2 | 1189*890*680 | Synchronous belt |

GMS10-4B | 0.5-10L | 4 | 2 | 2 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 380V | 2.2 | 742*890*1111 | Synchronous belt |

GMS20-4 | 0.5-20L | 4 | 2 | 3 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 2.2 | 1309*1128*724 | Chain wheel |

GMS30-4 | 1-30L | 4 | 1 | 3 | φ80 | 425 | 35~290 | φ60-φ360 | 0~200 | 380V | 4 | 1328*1048*680 | Synchronous belt |

GMS3-8 | 0.5-3L | 8 | 2 | 3 | φ50 | 230 | 76~230 | φ70-φ200 | 0-280 | 380V | 1.1 | 780*717*965 | Belt |

GMS5-8 | 0.5-5L | 8 | 2 | 3 | φ60 | 310 | 67~280 | φ70-φ260 | 0-270 | 380V | 2.2 | 1020*868*950 | Chain wheel |

GMS10-8 | 0.5-10L | 8 | 2 | 4 | φ70 | 410 | 67~302 | φ60-φ280 | 0~220 | 380V | 3 | 1210*890*1050 | Chain wheel |

GMS20-8 | 0.5-20L | 8 | 2 | 4 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 3 | 1390*1128*1100 | Chain wheel |