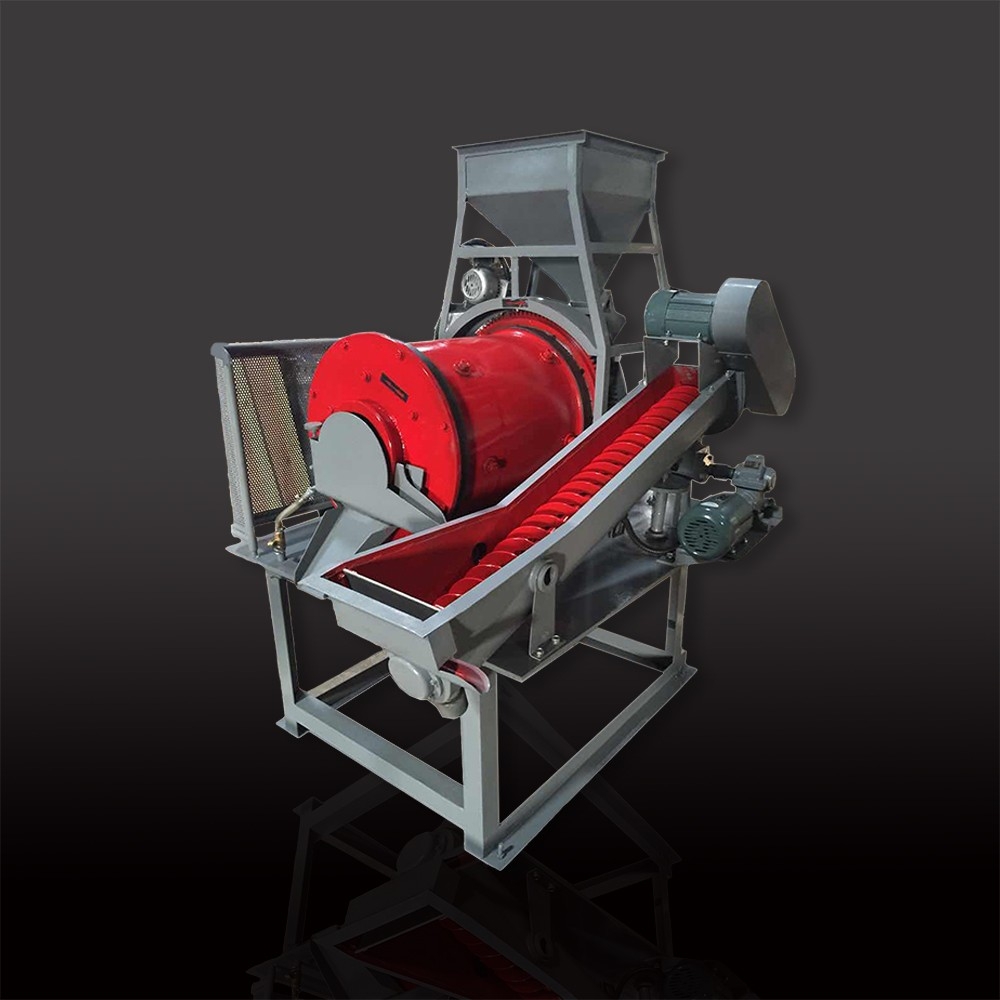

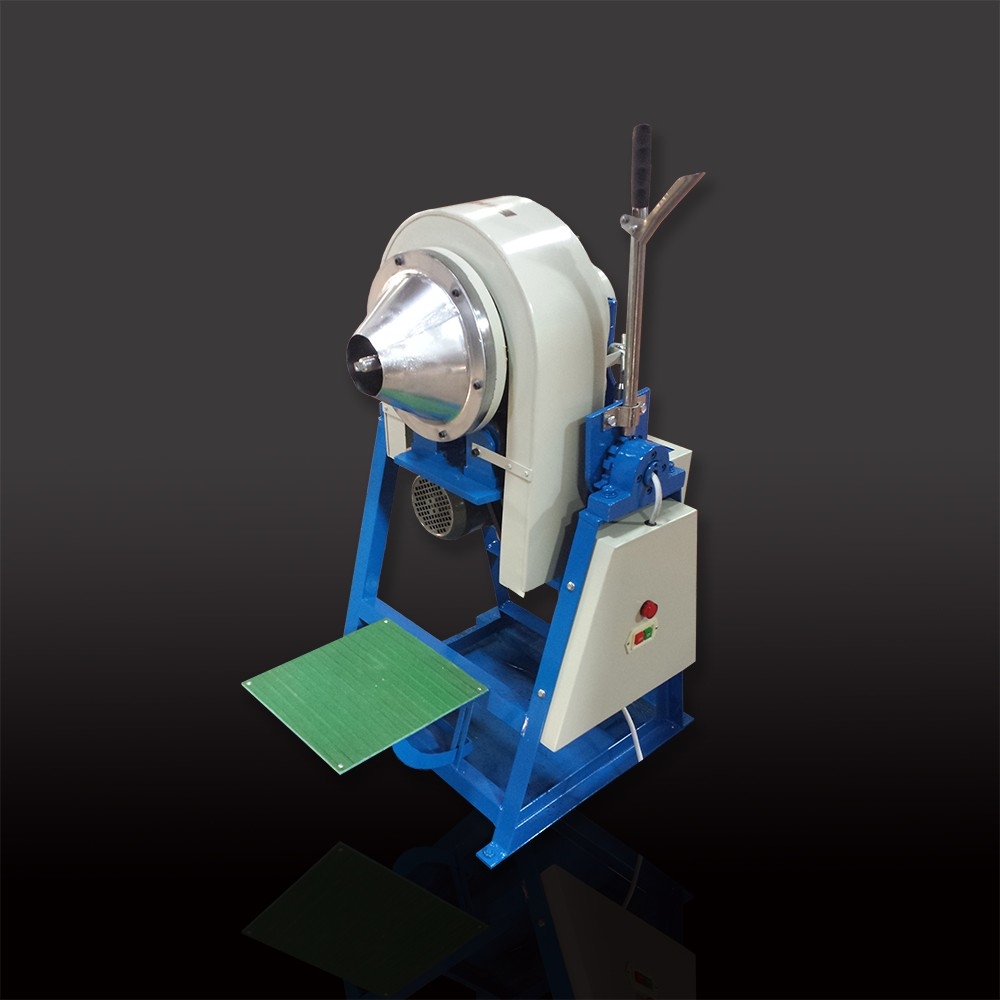

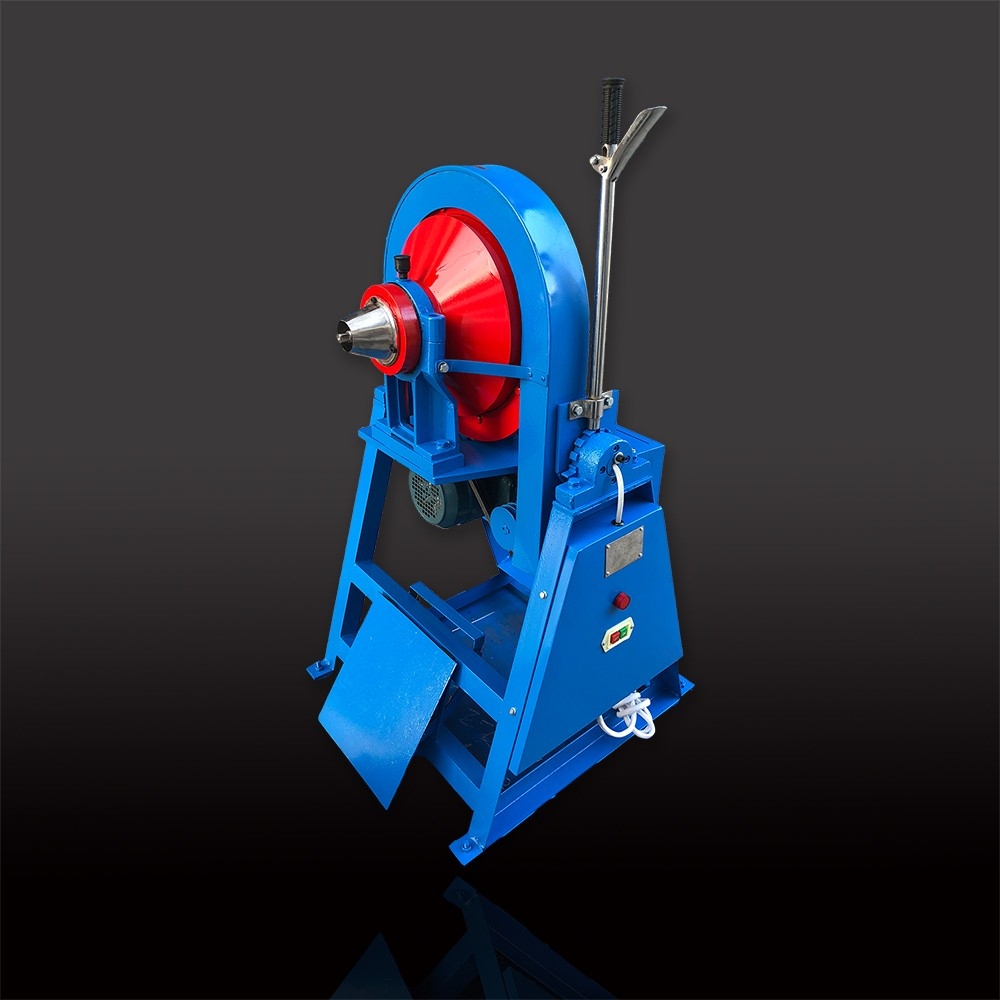

Continuous Rod Mill

GTEK Continuous Rod Mill/ Closed Circuit Rod Mill With Spiral Classifier is used in wet grinding circuit or determining grindability index of ore in mineral, chemical or industrial feasibility testing or pilot plant applications.

Description

GTEK Continuous Rod Mill/ Closed Circuit Rod Mill With Spiral Classifier is used in wet grinding circuit or determining grindability index of ore in mineral, chemical or industrial feasibility testing or pilot plant applications.

Φ420×600 Continuous Overflow Rod Mill is mainly consists of the feeding part, grinding part, discharging part, classification part and conveying part. Same as the Pilot Ball-Rod Mill.

Check the details in "working principle".

Working Principle

1.Feeding Part

Consist of vibrating feeder with feed bin and volute feeder.After opening the gate of feed bin, the material is fed to the volute feeder evenly and continuously, and is fed to the drum with water by volute feeder.The feed quantity is regulated by opening size of the gate and rotation speed of the drum.

The volute feeder of the feeding system is a spiral shape spoon, by which the feed ore and return sand can be lifted and fed to the inside of drum.The feed volute is connected to the feed end of the drum and is covered in the volute feeder housing.The volute feeder housing can be disassembled and is easy for cleaning and inspection.

2.Grinding Part

The grinding part is a Φ420×600 lined with 6 corrugated manganese steel liner, the drum is supported by two pairs of rollers by two rims welded outside the drum.There is gear ring close to the feed part, and the drum is driven to rotate by means of bridge drive gear engagement.

3.Discharging Part

The ground product is discharged overflow from the discharging end, and flow into the spiral separator automatically by means of the gradient of discharging chute. There is hose connector welded on the upper end of discharge chute, which is connected with the water supply pipe by rubber hose.The water supply pipe is coupled with stopcock so as to adjust the quantity of water.There is a shield plugged outside the chute to avoid splash of discharge ore slurry.

4.Classification Part

The classification part is a φ150×1400mm spiral classifier. Make use of the inlet hole of discharging chute as one of the support point of one end,the whole spiral classifier can be turned to a certain degree of angle to achieve different inclination requirements.The other end is supported by screw rod, turn the hand wheel with sleeve nut to adjust the degree of slope,so as to control quantity of return sand and overflow fineness.

5.Conveying Part

The conveying part is a φ90×600mm spiral conveyor which connect to the spiral classifier and volute feeder housing, the sand from spiral classifier is evenly and continuously fed to the volute feeder housing.The classifier sand and raw ore are fed to the drum of rod mill by volute feeder. So the spiral classifier and rod mill constitute a closed grinding system, and continuous grinding is realized.The whole component is simple in structure, reasonable in sealing, reliable in driving and easy in installation and maintenance.

Water Supply and Electricity System

1.Water Supply System

There is a inlet water nozzle, after the water is supplied through this inlet water nozzle,the inlet water is divided into two parts, supplying water for both feeding part and discharging part, so as to satisfy the water requirements for working of the two parts.

During operation, on one hand, pay attention to check the water, check the sealing conditions of water pipe joints; on the other hand, due to the vertical structure of the two water inlet, so violet impact should be avoided which will result in damage to the pipelines. To ensure the effect of grinding and classification, constant pressure water tank can be used for water source.

2.Electricity System

The different parts of the mill are driven by independent motors and can be individually controlled.

Features

Easy operation, installation and maintenance;

Closed circuit system enhance the grinding effection apparently;

Four motors drive independently and can be individually controlled;

Quality assurance, long service life.

1.Rod Mill

Item | Unit | Specification | ||

Mill Shell Size | mm | Φ420×600 | ||

Mill Speed | RPM | 57 | ||

Mill Volume | L | 80 | ||

Rod Charge | Φ35-Φ40 | kg | 45 | |

Φ30 | kg | 60 | ||

Φ25 | kg | 50 | ||

Feed Size | mm | ≤6 | ||

Discharge Size | mm | ≤0.074 | ||

Feed Volume | cm³ | 700 | ||

Capacity | Kg/h | 150 | ||

Motor

| Model |

| 100L-6 | |

Power | kw | 2.2 | ||

Speed | RPM | 920 | ||

Dimensions | mm |

| ||

Weight | kg | 800 | ||

2.Sprial Classifier

Item | Unit | Specification | ||

Spiral Diameter | mm | Φ150 | ||

Spiral Length | mm | 1400 | ||

Overflow end width | mm | 240 | ||

Tilt adjustment range | ° | 15°30’,22° | ||

Maximum Return Sand Ratio | % | 300 | ||

Spiral Speed |

| 18,23,30 | ||

Motor | Model |

| YS7124-4 | |

Power | kw | 0.55 | ||

Speed | RPM | 1400 | ||

Feed Size | mm | ≤6 | ||

Discharge Size | mm | ≤0.074 | ||

Feed Volume | cm³ | 700 | ||

Capacity | Kg/h | 150 | ||

Motor

| Model |

| 100L-6 | |

Power | kw | 1.5 | ||

Speed | RPM | 920 | ||

Dimensions | mm |

| ||

Weight | kg | 800 | ||

3.Ore Bin Vibratory Feeder

Item | Unit | Specification |

Bin volume | L | 35 |

Vibratory Frequency | RPM | 19 |

Feed Capacity | Kg/h | 6-200 |

Motor |

| Share with spiral conveyor |

4.Spiral Conveyor

Item | Unit | Specification | |

Spiral Size | mm | Φ90×600 | |

Spiral Speed | RPM | 38 | |

Motor | Model |

| AO2-6314 |

Power | kw | 0.12 | |

Speed | RPM | 1400 | |