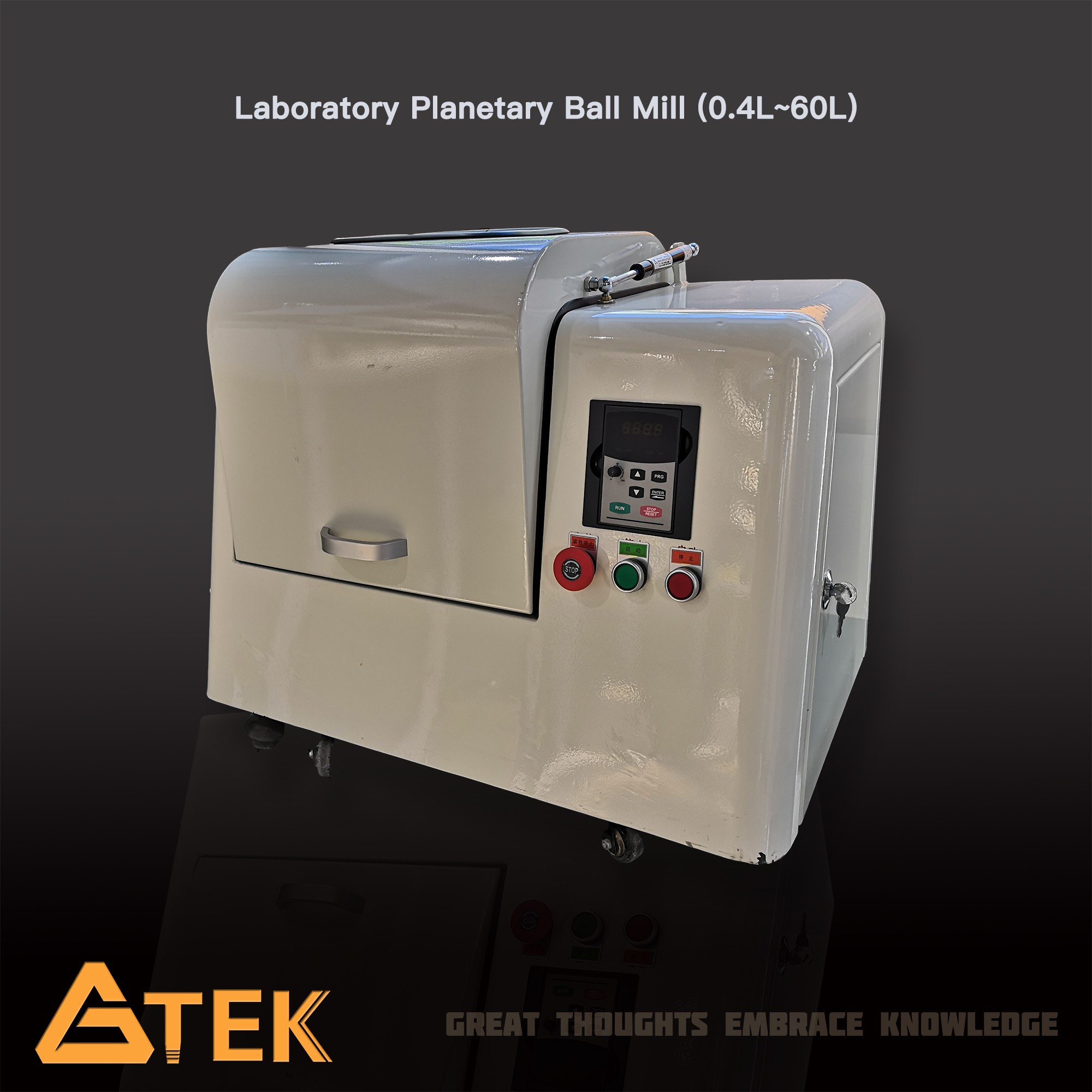

Planetary Ball Mill

GTEK Planetary Ball Mill is designed for mixing, fine grinding, and preparing small volume high-tech material production. And we also provide various planetary ball for special demands, such like: Full-Directional Planetary Ball Mill, Liquid Nitrogen Cooling Planetary Ball Mill, Air-Conditioning Cooling Planetary Ball Mill.

Description

GTEK Planetary Ball Mill is designed for mixing, fine grinding, and preparing small volume high-tech material production. The product features with small volume, high efficiency and low noise. If mated with vacuum ball milling jars, it can grind samples in vacuum or inert gas. The product is extensively used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry, Medicine and Environmental Protection etc..

How to chose the material of jars?

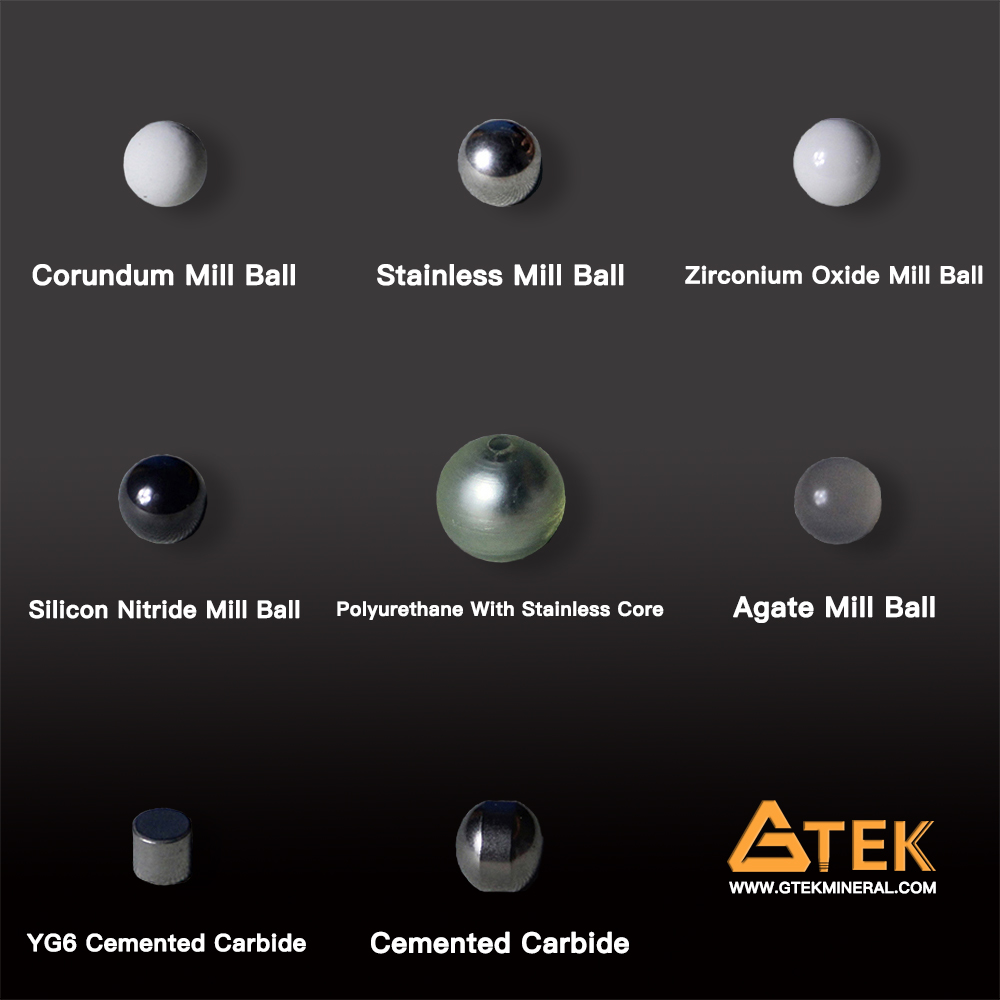

Material of grinding jars | Advantages | Fields of application |

Hardened,stainless steel | Most widely used/ Acid and alkali resistance | Common metal and non-metal materials |

Zirconium oxide | Super-high wear resistance/ High strength/ No impurities/ High corrosion resistance/ Good temperature resistance | Grinding measurement of rare-earth material, Precious metals, Electronic materials, Pigment and coating material, Magnetic material, etc... |

Agate | High purity and pollution-free/Less heat production | Food industry, Biology, Medical, Heavy metal detection, Dyestuff development,etc... |

Corundum | High hardness (but breakable)/ High temperature resistance/ High corrosion resistance/ High strength/Super-high wear resistance | Electronic ceramics, Magnetic material, Pigment and coating material, Special cement, Enamel glaze, etc... |

Polyurethane | High wear resistance/ No impurities | Electronics industry, Battery materials, etc... |

Nylon | High strength/ Free of metal impurities/Good toughness | Precious metals, Electronic ceramics, Magnetic materials, Pigment and coating material, etc... |

Silicon nitride | Super-high temperature resistance/ Super-high wear resistance/ High hardness |

Abrasive samples, metal-free grinding, etc...

|

Tungsten carbide | Super-high wear resistance/ High hardness/ High corrosion resistance | Widely used in most advanced industries |

PTFE | High(Low) temperature resistance/ High corrosion resistance/ Aging resistance/ Non adherence /No toxic harm | Electronics industry, Battery materials, etc... |

How to chose the suitable ball diameter?

Type of sample material | Suitable grinding ball diameter |

Hard samples with a maximum feed size of 10mm | 30mm* or 40mm* |

Average feed size of ≤ 5mm | 20mm*,15mm or 10mm |

Fine material < 0.5mm | 10mm or smaller |

Homogenisation of dry or liquid samples | 20mm*,10mm or smaller |

Homogenisation of viscous samples | 20mm* |

Optional mill ball

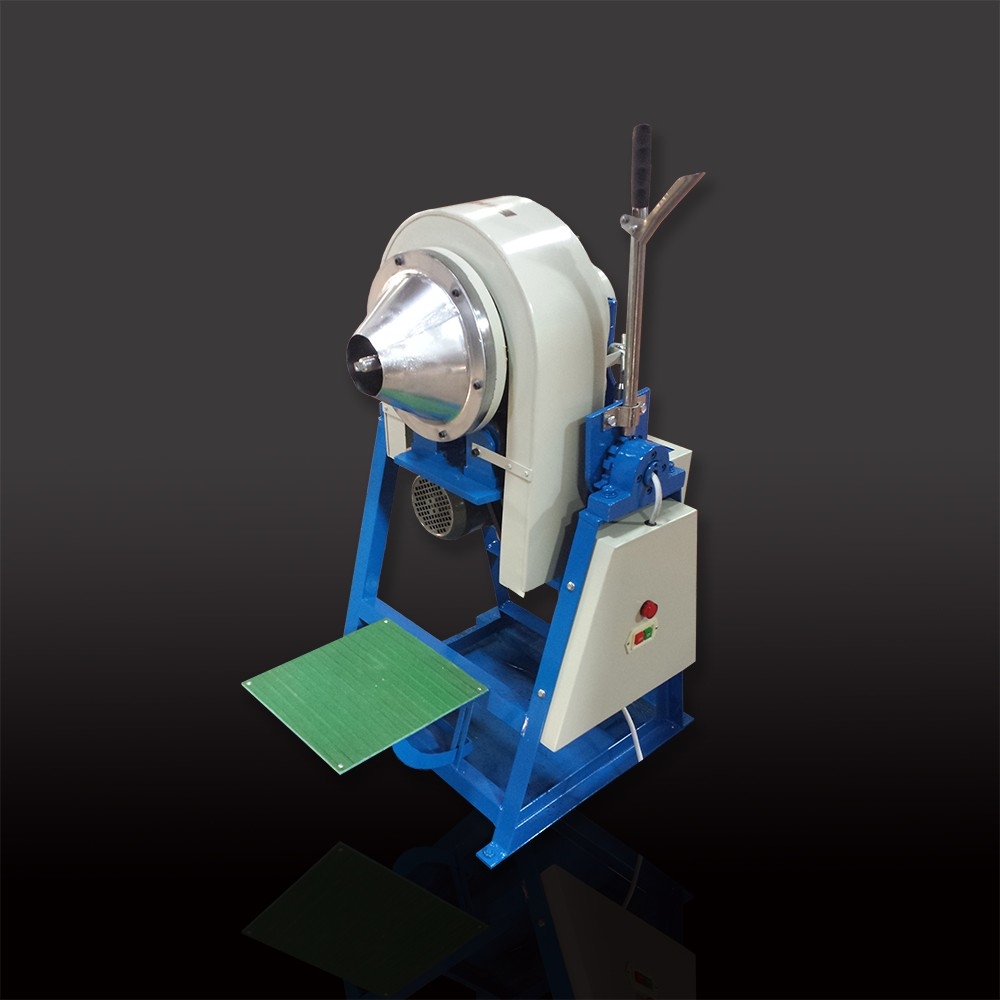

Optional vacuum grinding jar

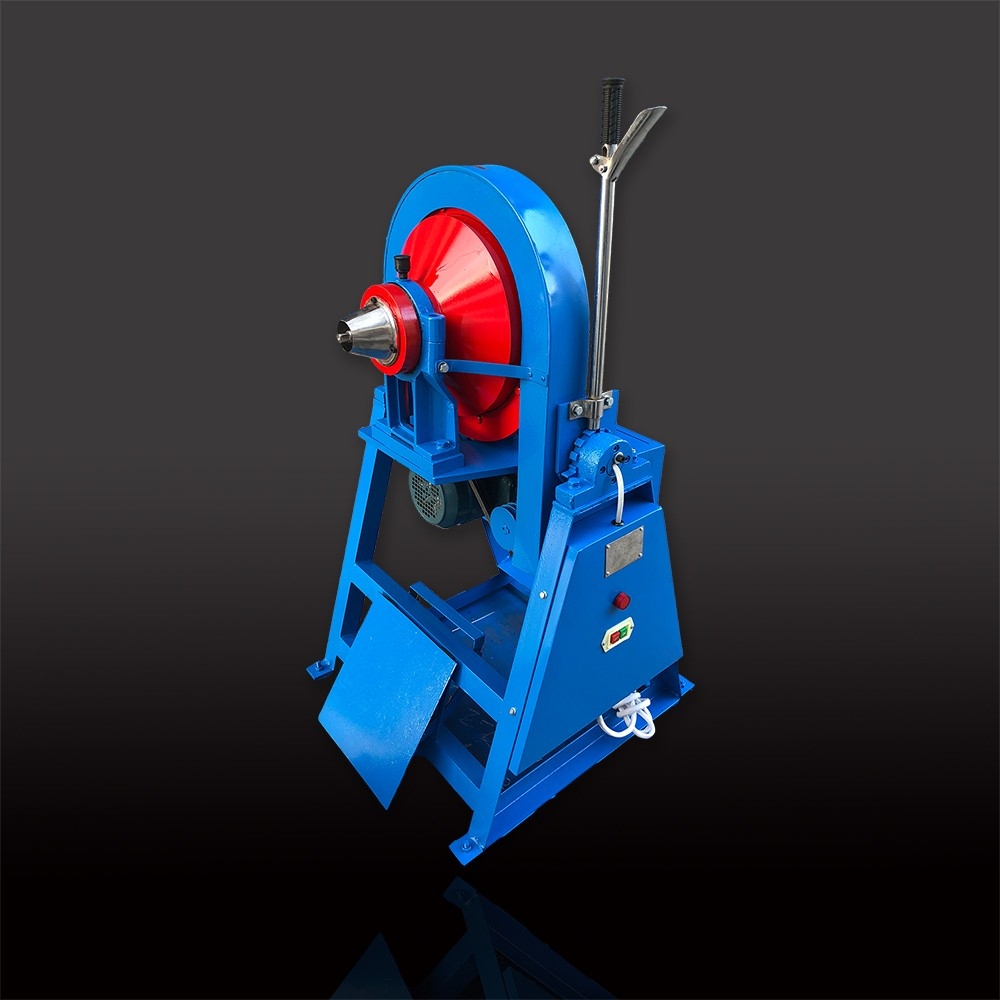

Working Principle

The Planetary Ball Mill has two or four ball grinding tanks installed on one turning plate. When the plate rotates, the tank axis makes planetary rotation in opposite direction and the grinding balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of discharge samples can be as small as 0.1 micron.

Features

1. Convenient operation: belt replacement is not needed;

2. Gear-driven mode offers an effective solutions to problems caused by belt driving, such as belt creep or abrasion;

3. Gear-driven ensures high uniformity, repeatability and low noise compare to belt-driven mills;

4. High rotation speed, high efficiency and fine granularity;

5. Four samples with different sizes and materials in one experiment;

6. Step-less speed regulation; optimal rotation speed selection according to experimental results;

7. Timed power-off, positive and negative revolving if required;

8. Compact structure, safe and reliable operation. Low noise, no pollution, and small wear;

9. Safety switch ensures automatic power-off when cover is open accidentally;

10. Height adjustable feet;

11. Loss-free wet grinding due to leak-proof grinding jars.

Model | Volume (L) | Adaptive Jar | Adaptive Vacuum Jar (ml) | Working Voltage | Work Mode | Grinding Range | |

Volume (ml) | Quantity | ||||||

YXQM-0.4L | 0.4 | 50-100 | 2-4 | 50 | 220V 50HZ | 2 or 4 jars working simultaneously | Dry/Wet Milling |

YXQM-1L | 1 | 50-250 | 50-100 | 220V 50HZ | |||

YXQM-2L | 2 | 50-500 | 50-250 | 220V 50HZ | |||

YXQM-4L | 4 | 50-1L | 100-500 | 220V 50HZ | |||

YXQM-8L | 8 | 500-2L | 250-1000 | 220V 50HZ | |||

YXQM-10L | 10 | 500-2.5L | 250-2.5L | 380V 50HZ | |||

YXQM-12L | 12 | 1L-3L | 500-3L | 380V 50HZ | |||

YXQM-16L | 16 | 1L-4L | 500-4L | 380V 50HZ | |||

YXQM-20L | 20 | 1L-5L | 1000-5L | 380V 50HZ | |||

YXQM-40L | 40 | 4L-10L | 3000-10L | 380V 50HZ | |||

YXQM-60L | 60 | 6L-15L | 5000-15L | 380V 50HZ | |||

YXQM-80L | 80 | 6L-20L | 5000-20L | 380V 50HZ | |||

YXQM-100L | 100 | 10L-25L | 9000-25L | 380V 50HZ | |||

YXQM-120L | 120 | 10L-30L | 9000-30L | 380V 50HZ | |||

YXQM-160L | 160 | 10L-40L | 9000-40L | 380V 50HZ | |||

Model | Speed Frequency | Transmission mode | Rotation speed (r/min adjustable) | Revolution speed (r/min adjustable) | Material Capacity | Input Granularity Size | Output Granularity Size |

YXQM-0.4L | Adjustable | Gear drive | 10-900 | 5-450 | Material +Mill balls < 2/3 volume | < 10 mm for soft material, < 3 mm for hard material | < 75um-0.1um(100nm) |

YXQM-1L | 10-900 | 5-450 | |||||

YXQM-2L | 10-800 | 5-400 | |||||

YXQM-4L | 10-800 | 5-400 | |||||

YXQM-8L | 10-640 | 5-320 | |||||

YXQM-10L | 10-640 | 5-320 | |||||

YXQM-12L | 10-640 | 5-320 | |||||

YXQM-16L | 10-560 | 5-280 | |||||

YXQM-20L | 10-460 | 5-230 | |||||

YXQM-40L | 10-440 | 5-220 | |||||

YXQM-60L | 10-360 | 5-180 | |||||

YXQM-80L | 10-360 | 5-180 | |||||

YXQM-100L | 10-360 | 5-180 | |||||

YXQM-120L | 10-360 | 5-180 | |||||

YXQM-160L | 10-320 | 5-160 | |||||