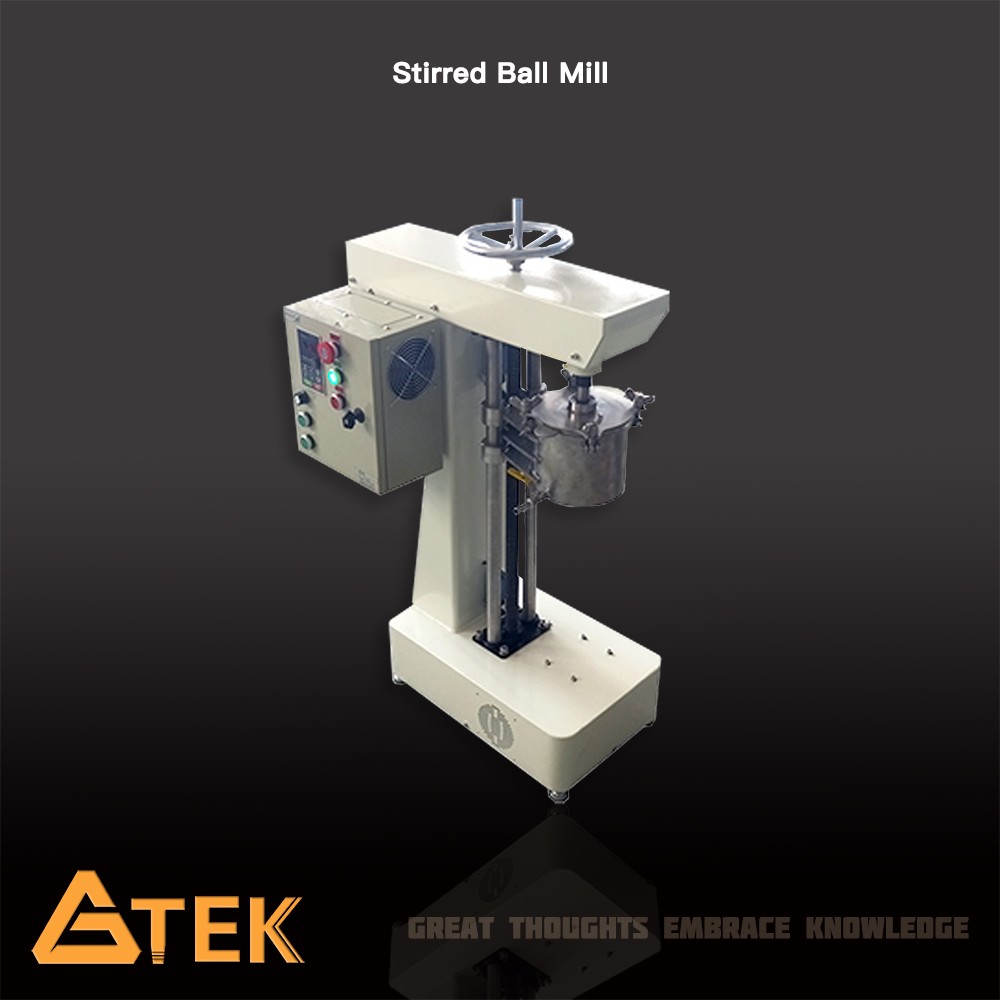

Attritor Ball Mill

GTEK Attritor Ball Mill or Stirred Mill is a grinding mill containing internally agitated media. It is a simple and effective method of grinding and dispersing fine and homogenous material quickly and repeatedly.

Description

GTEK Attritor Mill or Stirred Ball Mill is a grinding mill containing internally agitated media. It is a simple and effective method of grinding and dispersing fine and homogenous material quickly and repeatedly.

GTEK laboratory size Attritor Mill or Stirred Ball Mill is designed with variable speed drive for different RPM selections. The Attritor Ball Mill can operate with wet or dry grinding, operate at controlled temperatures and vary grinding speed, change media type and size. Results are repeatable from one batch to another so the Attritor Ball Mill is ideal for formulating, quality control, pilot plant and scale up studies.

A series of metal-contamination-free machines are specially designed for the ceramic industry. Several types of ceramic and polymer materials have been developed to line or sleeve the machine's internal parts, including alumina, zirconia, silicon nitride, tungsten carbide, rubber, polyurethane.

Common applications are chemicals, ferrites, metal oxides, minerals, metal and nonmetal, painting, ceramic, rare-earth, hard alloy.

Working Principle

The operation of a Attritor Ball Mill is simple and effective. The material to be ground and the grinding media are placed in a stationary, jacketed grinding tank. The material and the media will be agitated by the shaft with cross arms, rotating in high speed. This causes the media to exert both shearing and impact forces on the material, resulting in optimum size reduction and dispersion. The material can be directly fed into the jacketed grinding tank of the mill. No need to premixing or pre-dispering. Temperature control either cooling or heating can be maintained with the use of jacketed tanks.

Features

1. Variable speed drive for different RPM selections.

2. Adjustable agitator shaft height to accommodate different size grinding media.

3. Easily removable tank for media discharge.

4. Stainless steel shaft with arms.

5. Replaceable tank with different materials available.

6. Jacketed tank for heating and cooling.

Model | Jar Volume (L) | Grinding Medium Quantity (L) | Capacity (L) | Driving Power (kW) | Feed Size (mm) | Discharge Size (μm) |

ZJM-1 | 1 | 0.5 | 0.5 | 0.37 | ≤5 | ≤1 |

ZJM-2 | 2 | 1 | 1 | 0.37 | ||

ZJM-3 | 3 | 1.5 | 1.5 | 0.37 | ||

ZJM-5 | 5 | 2.5 | 2.5 | 1.5 | ||

ZJM-10 | 10 | 5 | 5 | 1.5 | ≤10 | |

ZJM-30 | 30 | 15 | 15 | 3 | ||

ZJM-70 | 70 | 35 | 35 | 5.5 | ||

ZJM-100 | 100 | 50 | 50 | 7.5 | ≤20 |