Vibratory Screener

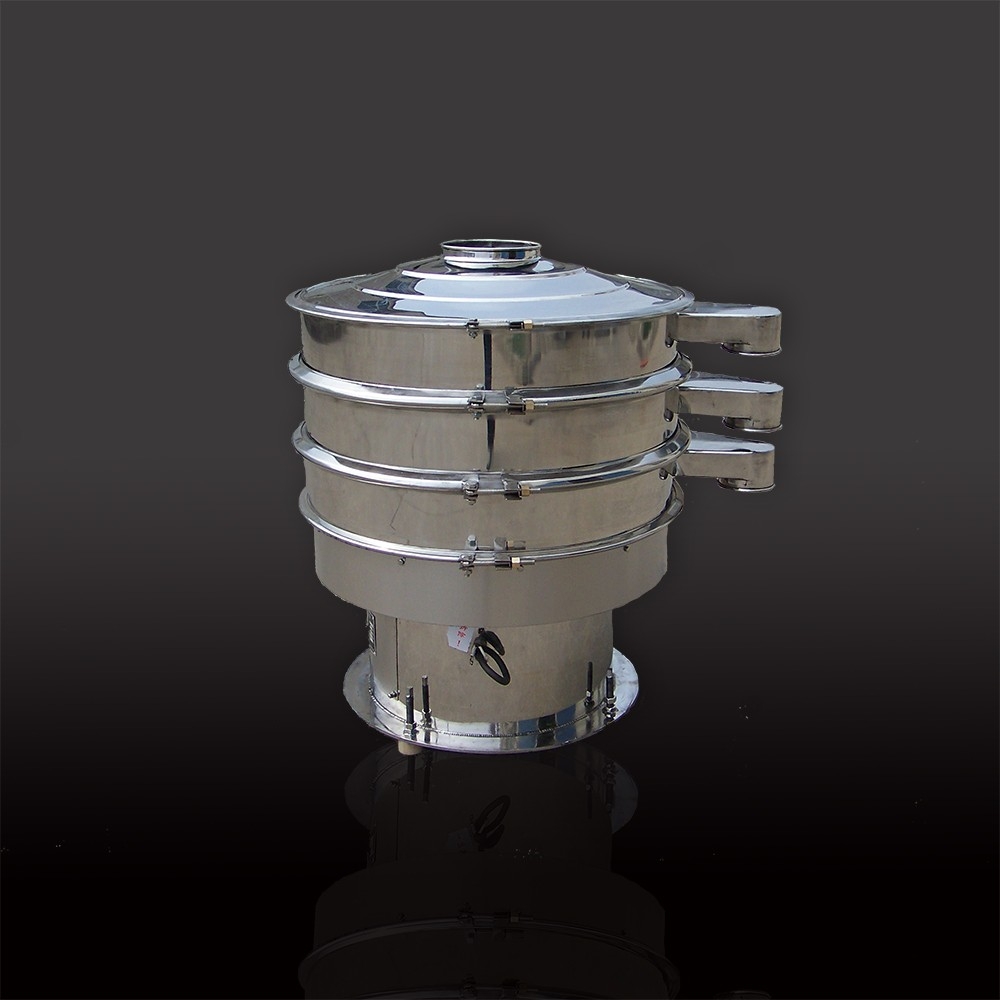

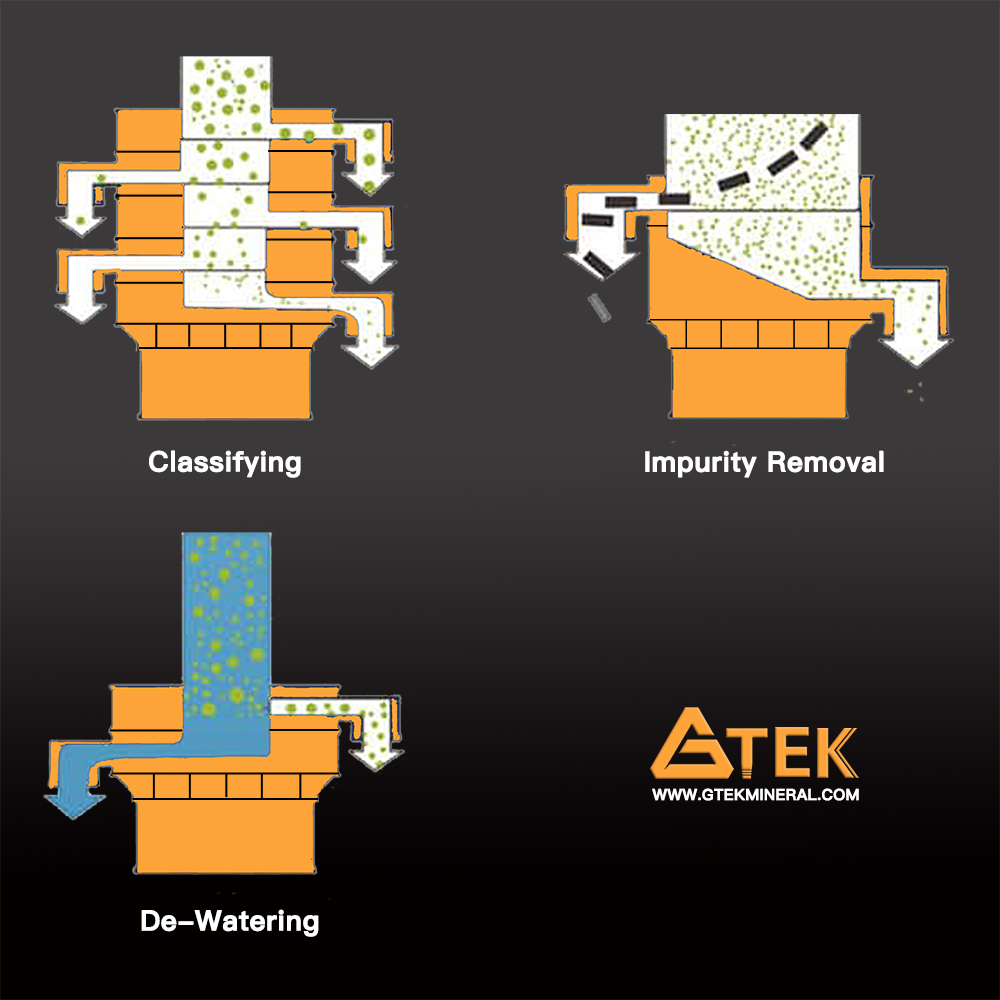

GTEK Circular Vibratory Screener/ Vibratory Sifter is designed to perform separation, scalping and grading processes for both dry and wet applications in pharmaceutical, chemical, food and cement industries.

Description

GTEK Circular Vibratory Screener/ Vibratory Sifter is designed to perform separation, scalping and grading processes for both dry and wet applications in pharmaceutical, chemical, food and cement industries. We offer an innovative range if such circular vibratory separate machines that feature enhanced screening capability, lower noise and rugged construction.

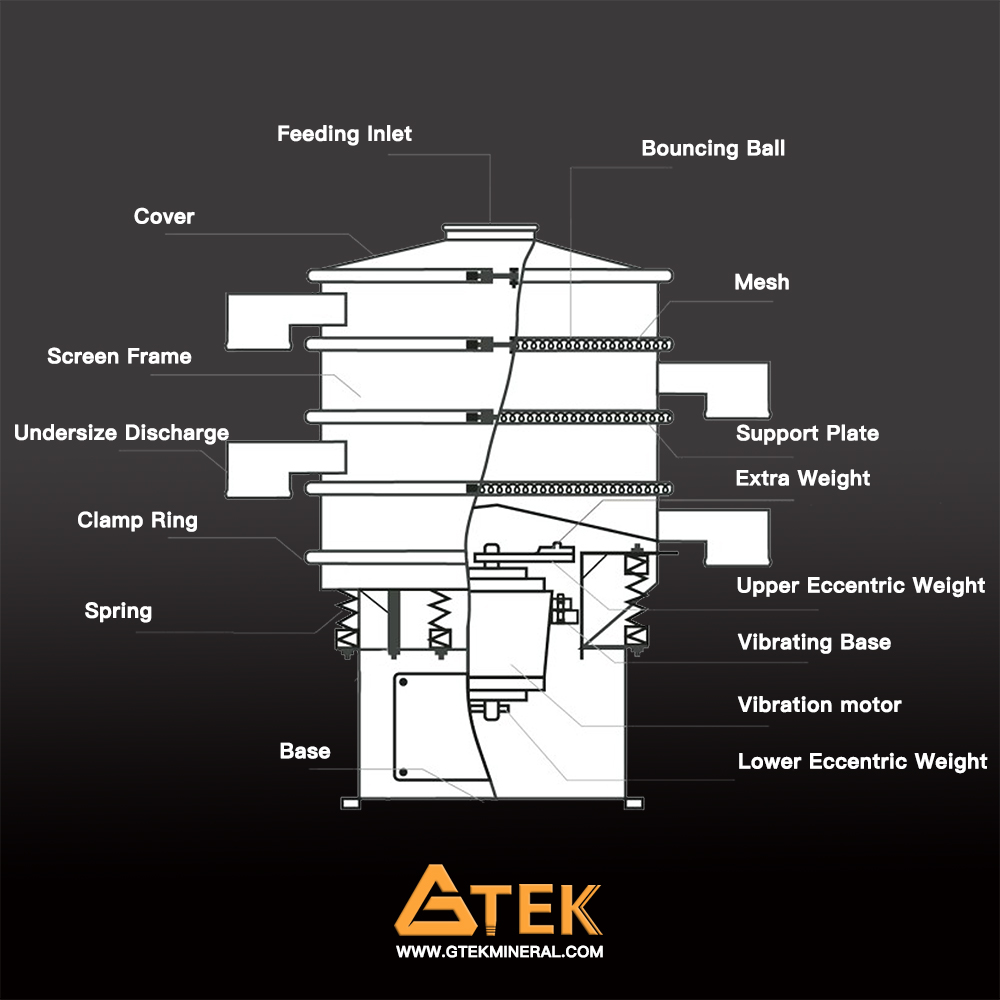

GTEK Circular Vibratory Screeners are suspended on rugged springs that allow it to vibrate freely while minimizing power consumption and preventing vibration transmission to the floor. The circular vibratory screener is fitted with vertical vibration motor, mesh frame and sieve room.

Vibratorty Sifter Structure

This high capacity circular vibrating screener industrial separator is widely used in industrial screener grading applications in numerous industries, such as food, metallurgy, ceramic, chemical, pharmaceutical, powder coatings and others.

Applications of Circular Vibratory Screener:

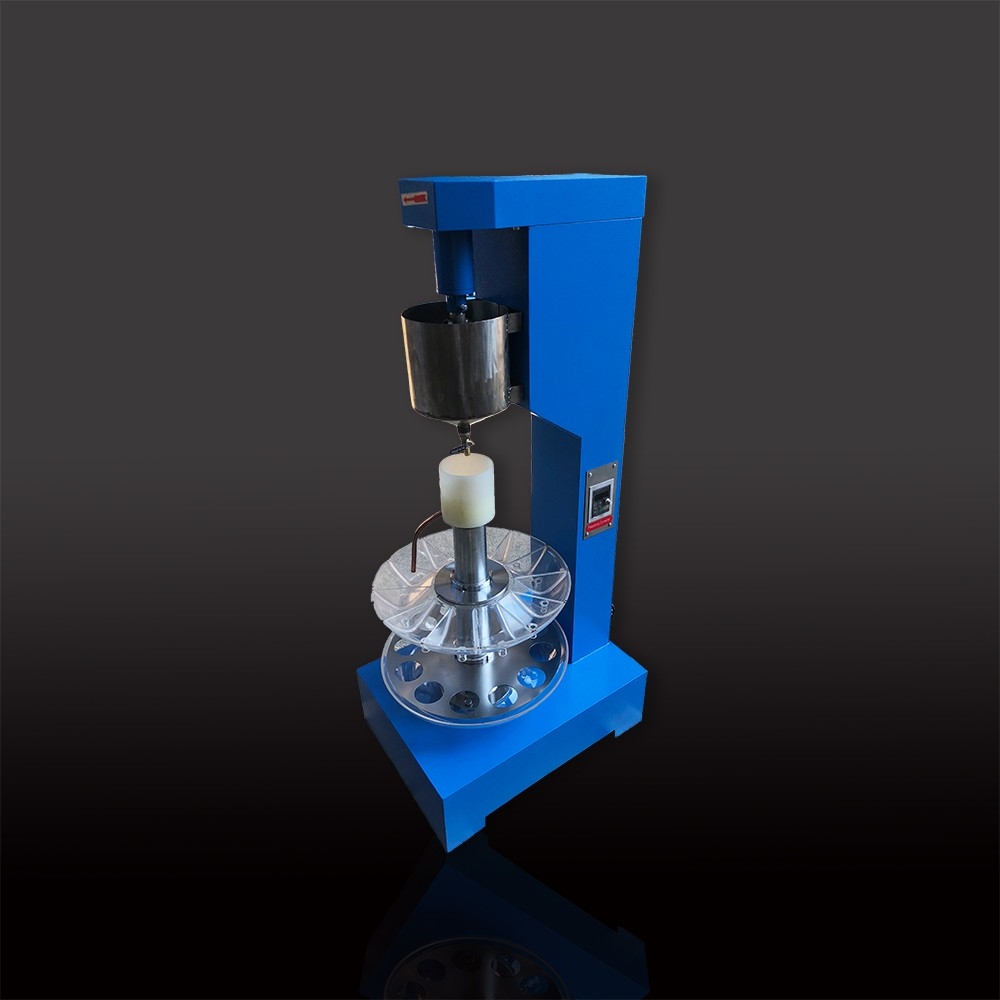

Working Principle

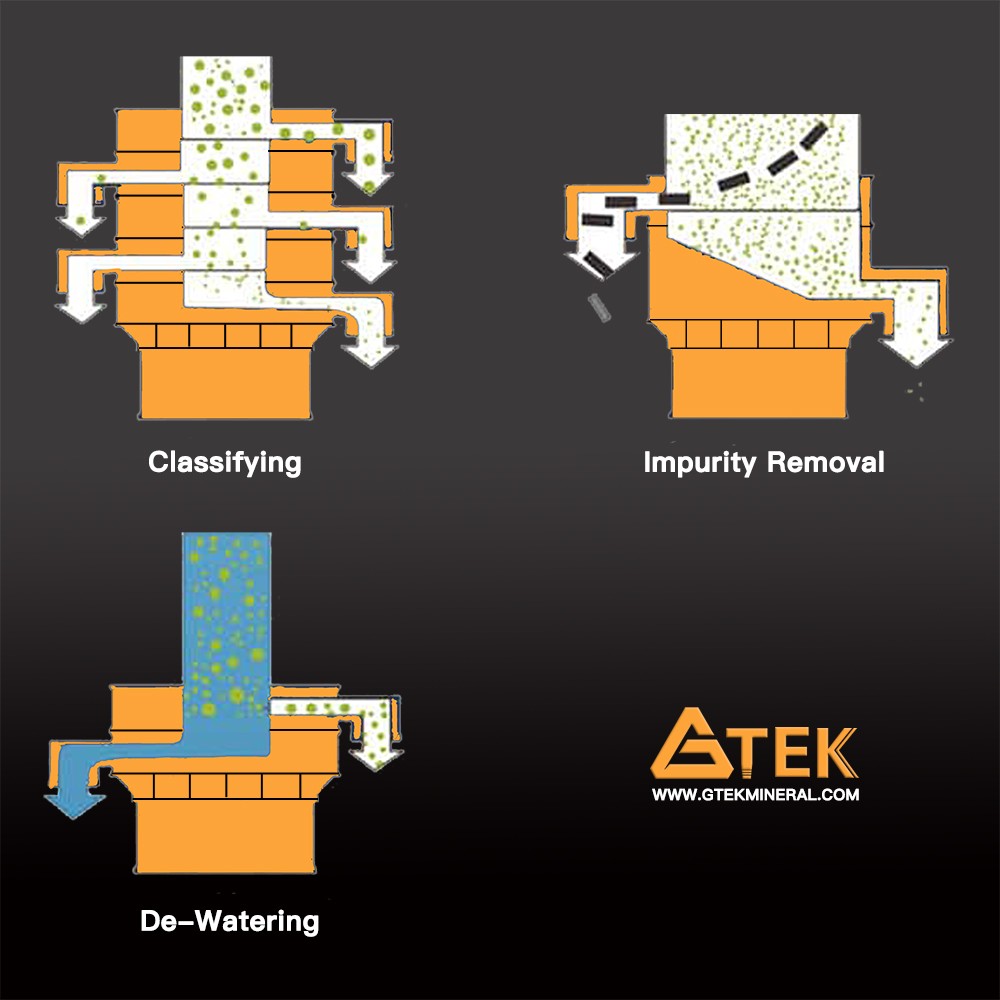

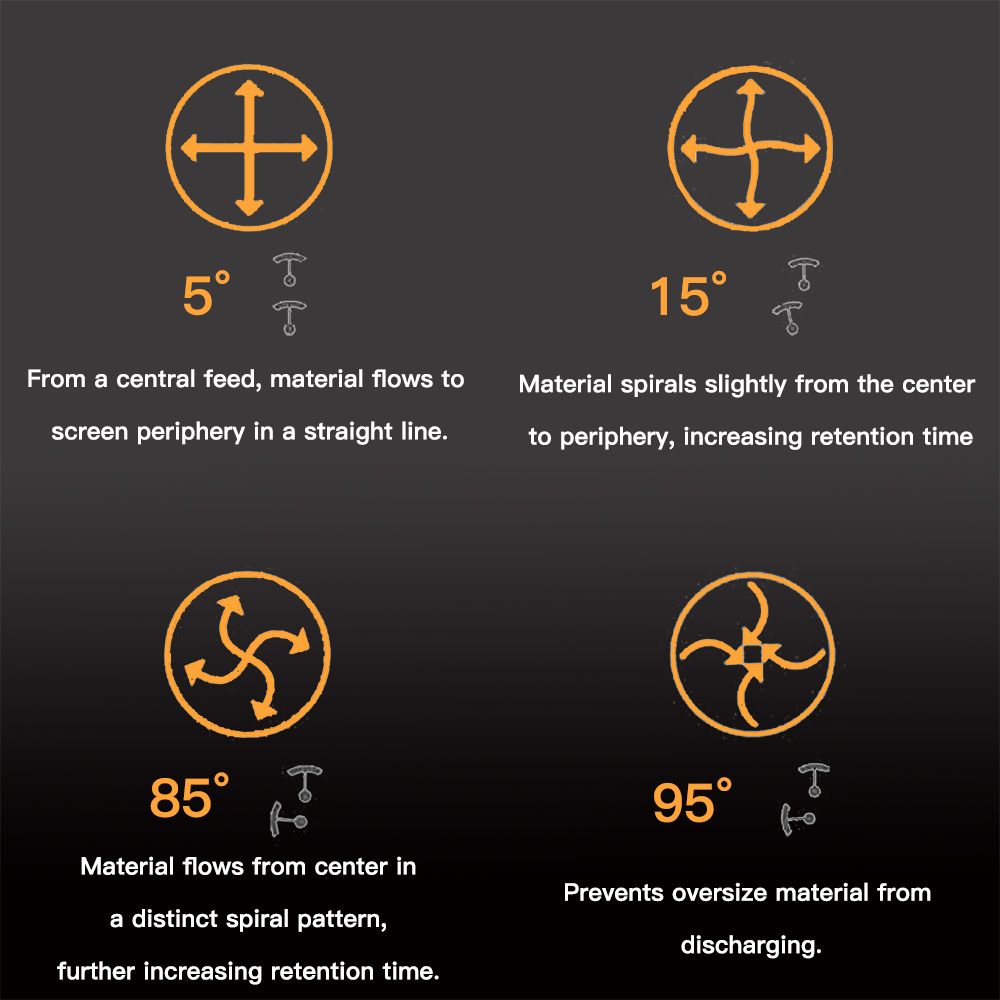

A Vibratory Screener is a Screen Separator/ Screening Machine that vibrates around its centre of gravity. Vibrating of screens is done by eccentric masses on the lower and upper ends of the motion, generating piece. Rotating the top mass in a circular motion, creates a horizontal plane vibration, causing material to travel across the stainless steel sieve and over to the periphery of the screen. The lower mass of these industrial sifters acts to tilt the machine, causing vertical and tangential vibrations of those planes.

Material is fed onto the center of the screen, causing particles larger than screen apertures to travel across the screen surface in controlled pathways, and exit through a discharge spout located at the screen’s periphery, while particles smaller than screen apertures pass through the screen onto a lower screen or exit through a lower discharge spout.

Adjust the angle between the Upper and the Lower Eccentric Weight to change the motion way of materials.

Features

1. Ideal for dry and wet grading.

2. High capacity and accurate separation.

3. Low Noise Level.

4. Small footprint.

5. Screens are easy and fast to change.

Model | Diameter (mm) | Effective Aera (m2) | Deck Number | Power (KW) | Max.Feed Size (mm) |

S400-B | 400 | 0.13 | 1-3 | 0.25 | 20 |

S600-B | 600 | 0.16 | 1-3 | 0.5 | 20 |

S800-B | 800 | 0.44 | 1-3 | 0.75 | 30 |

S1000-B | 1000 | 0.63 | 1-3 | 0.8 | 30 |

S1200-B | 1200 | 1.03 | 1-3 | 1.5 | 30 |

S1500-B | 1500 | 1.65 | 1-3 | 2.2 | 50 |

S1800-B | 1800 | 2.4 | 1-3 | 2.5 | 50 |

S2000-B | 2000 | 2.98 | 1-3 | 2.5 | 60 |