DC Series Jaw Crusher

GTEK DC Series Jaw Crusher is an upgraded model of PE Series Jaw Crusher, it is mianly used as primary crushers in several applications, including mining, quarrying, aggregates, recycling and construction industry.

Description

Jaw Crushers are mainly used as primary crushers in several applications including mining, quarrying, aggregates, recycling and construction industry. Jaw Crushers are one of the most commonly used crushers due to their ability to crushes all kinds of materials of any hardness,as well as their low-cost operation and easy maintenance.

GTEK DC Series Jaw Crusher is an upgraded model of PE Series Jaw Crusher, and it can produce more and finer products.GTEK offers a range of jaw crushers for different feed and grain sizes and performance capacity. Our jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout. The components of jaw crusher are of high strength design to accept high power draw. Manganese steel is used for both fixed and movable jaw faces. Heavy flywheels allow crushing peaks on tough materials.

DC Series Jaw Crusher

Working Principle

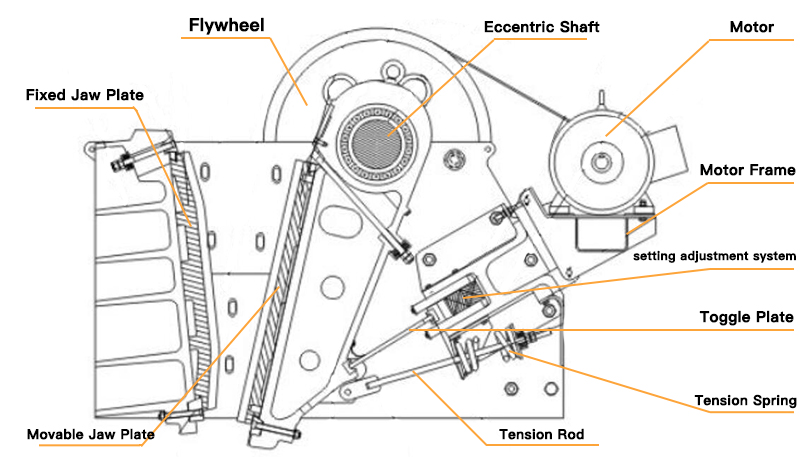

Jaw Crushers reduce rocks or ore by means of compression.This mechanical pressure is achieved by the crusher's two jaws dies/ jaw plates, one of which is stationary and the other is movable.These two vertical manganese jaw dies/ jaw plates create a V-shaped cavity called the crushing chamber.The material is fed into the top of and the movable jaw compresses material against the fixed jaw, crushing the material to the desired size. The material exits the jaw through the bottom of the crusher otherwise known as the discharge opening. Changing the discharge opening controls the product size made by the crusher.

A DC Series Jaw Crusher consists of flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material.

Features

1.Heavy Duty Jaw Crusher Design

2.Simple construction

3.Long Life

4.Reliable operation

5.Cost Effective

6.High Productivity

7.Easy maintenance

8.Lower running cost

9.Programmable grease filling time and quantity

Model | DC75 | DC90 | DC106 | DC125 | DC160 | |

Feed Opening Size (mm*mm) | 500*750 | 600*900 | 750*1060 | 950*1250 | 1200*1600 | |

Max. Feeding Size (mm) | 420 | 500 | 630 | 800 | 1000 | |

Motor Power (kW) | 55-75 | 90 | 132 | 160 | 250 | |

Weight (t) | 9.5 | 12.5 | 23.5 | 42.8 | 75 | |

Discharge Port Size (mm) | Particle Size of Product (mm) | Capacity (t/h) | ||||

40 | 0-60 | 55-80 |

|

|

|

|

50 | 0-75 | 70-90 |

|

|

|

|

60 | 0-90 | 80-115 | 120-155 |

|

|

|

70 | 0-105 | 105-130 | 140-180 | 155-200 |

|

|

80 | 0-120 | 120-150 | 160-210 | 175-230 |

|

|

90 | 0-135 | 130-170 | 180-235 | 200-260 |

|

|

100 | 0-150 | 150-190 | 200-260 | 220-290 | 290-380 |

|

125 | 0-185 | 190-260 |

| 280-365 | 350-455 |

|

150 | 0-225 | 250-340 |

| 335-435 | 410-535 | 520-675 |

175 | 0-260 |

|

| 390-510 | 470-610 | 595-775 |

200 | 0-300 |

|

| 445-580 | 530-690 | 675-880 |

225 | 0-340 |

|

|

| 590-770 | 750-975 |

250 | 0-375 |

|

|

| 650-845 | 825-1070 |

275 | 0-410 |

|

|

|

| 900-1170 |

300 | 0-450 |

|

|

|

| 980-1270 |