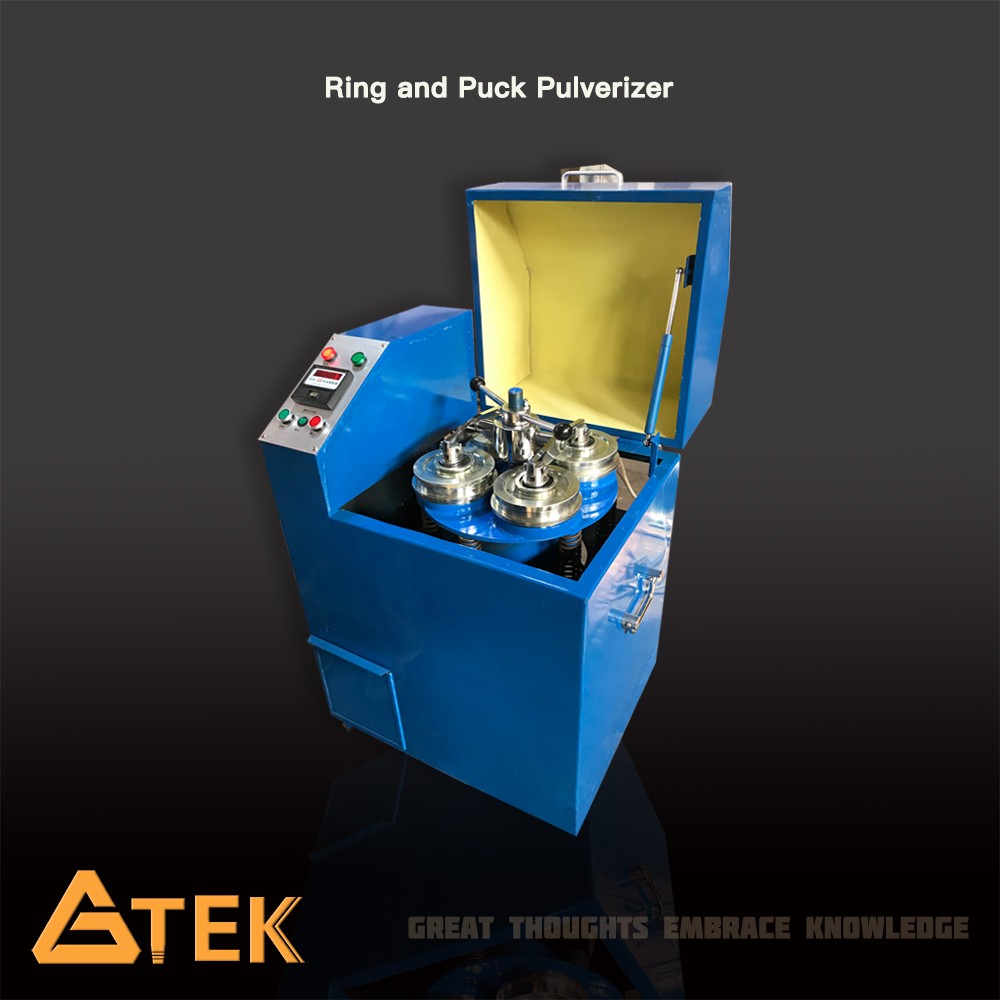

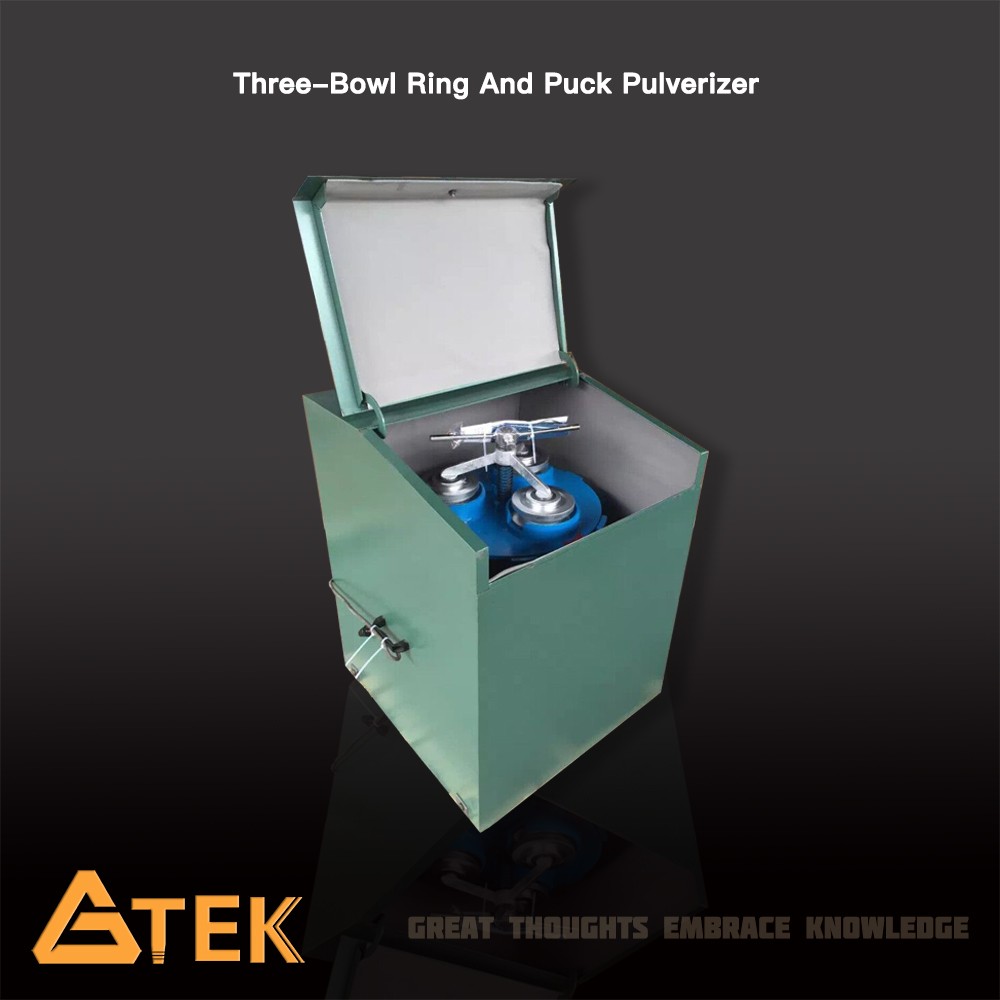

Ring and Puck Pulverizer

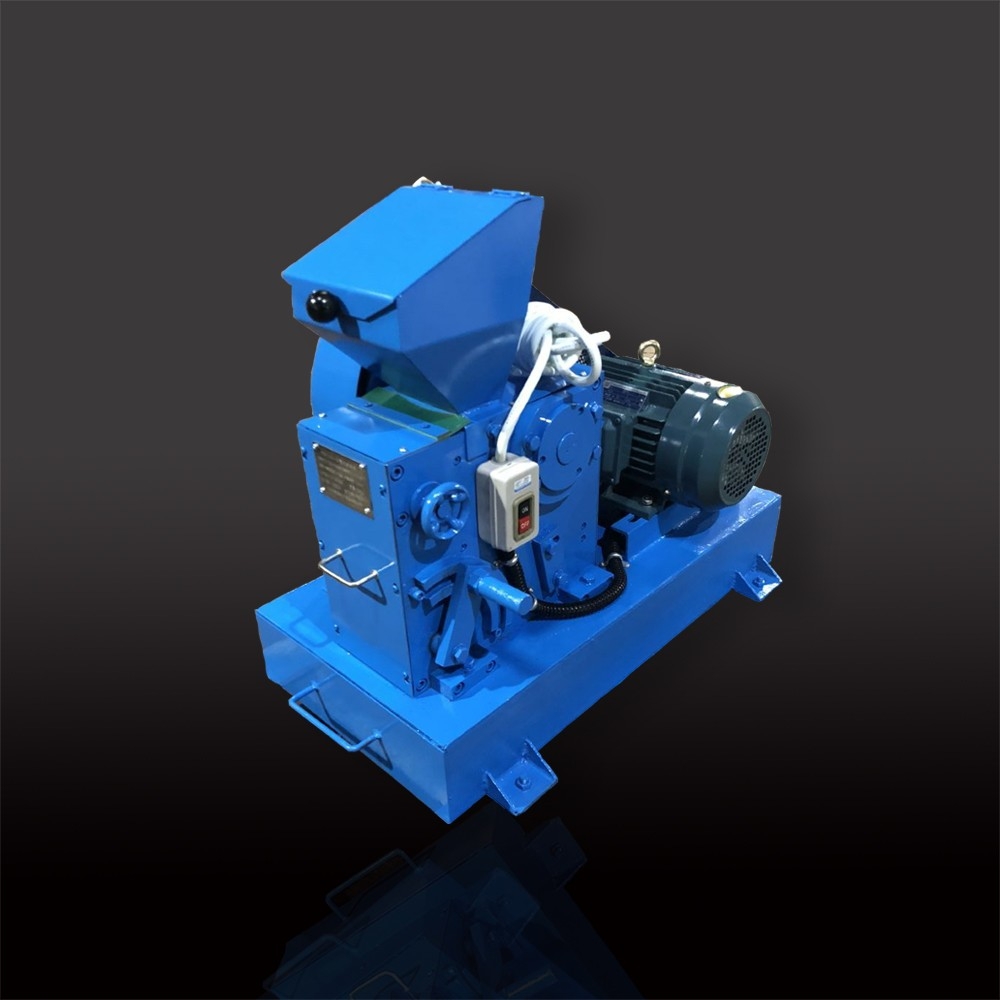

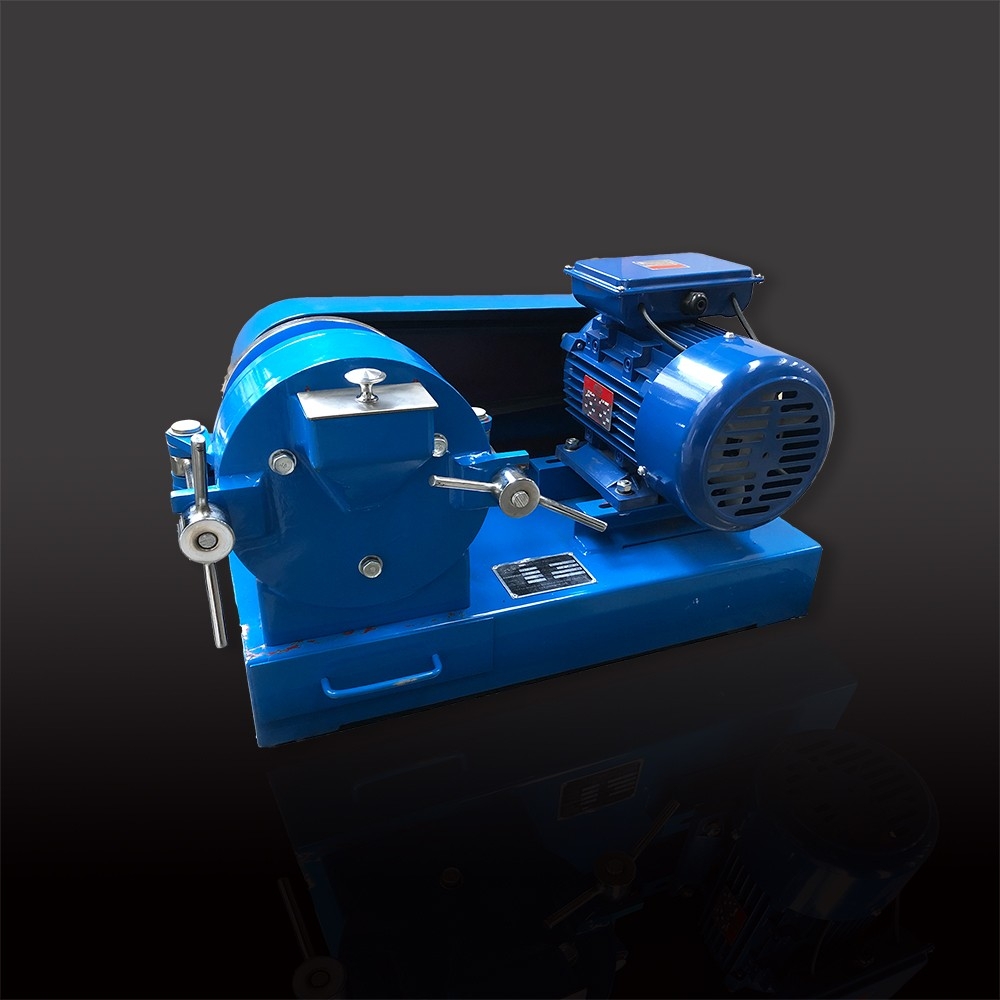

GTEK Ring And Puck Pulverizer can be used for efficient grinding of medium-hard and brittle material in mining, metallurgy, ceramic industry, cement, building material, chemical industry and power plant.

Description

GTEK Ring And Puck Pulverizer/ Ring And Puck Mill can be used for efficient grinding of medium-hard and brittle material in the fields of mining, metallurgy, ceramic industry, cement, building material, chemical industry and power plant. It is an ideal pulverizer when it comes to preparation of samples for testing.

The material is fed to a fully closed bowl with a ring and a puck inside. A special designed motor drives the shaft of the power arm to rotate. The vibration plate with the grinding bowl is subjected to circular horizontal vibrations. The centrifugal force acting on the grinding rings in the bowl results in extreme pressure, impact and frictional forces acting on the sample, the material is reduced to analytical fineness rapidly.

Working Principle

GTEK Vibration Pulverizer has a single or servial working positions. Each one contains a ring and a puck. When the working process goes on, the cover of the "bowl" must be checked and make sure it's sealed by the fixing device. As the vibrator starts working, the ring and the puck will have a omni-directional movement to impact the sample into finer particles.

Features

1.Exquisite design, long service time;

2.Quick, loss-free and reproducible grinding;

3.Steadily and smoothly running, low noise;

4.Uniform particle size.

Model | Bowl Mat | Bowl Qty (pcs) | Capacity (g/pcs) | Fd Size (mm) | Dschg Size (mesh) | Plvrz Time (min) | Pow (kW) | Wght (kg) | Dimensions (L×W×H) (mm) | ||

GJ-I | HMS | 1 | 150 | <12 | 120-200 | 3-5 | 1.1 | 180 | 640 | 560 | 745 |

GJ-II | HMS | 1 | 400 | <15 | 120-200 | 3-5 | 1.1 | 310 | 740 | 740 | 910 |

GJ-AX | HMS | 7 | 100 | <12 | 120-200 | 3-5 | 1.1 | 350 | 740 | 740 | 910 |

GJ-A | corundum | 1 | 50 | <5 | 120-200 | 10-15 | 0.55 | 80 | 420 | 480 | 640 |

GJ-B | corundum | 3 | 50 | <5 | 120-200 | 10-15 | 1.1 | 160 | 560 | 560 | 800 |

1MZ-100 | HMS | 1 | 100 | <12 | 120-200 | 3-5 | 1.1 | 160 | 560 | 560 | 800 |

2MZ-100 | HMS | 2 | 100 | <12 | 120-200 | 3-5 | 1.1 | 180 | 560 | 560 | 800 |

3MZ-100 | HMS | 3 | 100 | <12 | 120-200 | 3-5 | 1.1 | 180 | 560 | 560 | 800 |

4MZ-100 | HMS | 4 | 100 | <12 | 120-200 | 10-15 | 1.1 | 320 | 740 | 740 | 910 |

5MZ-100 | HMS | 5 | 100 | <12 | 120-200 | 10-15 | 1.1 | 330 | 740 | 740 | 910 |

6MZ-100 | HMS | 6 | 100 | <12 | 120-200 | 3-5 | 1.1 | 340 | 740 | 740 | 910 |

1MZ-200 | HMS | 1 | 200 | <15 | 120-200 | 3-5 | 1.1 | 180 | 560 | 560 | 800 |

2MZ-200 | HMS | 2 | 200 | <15 | 120-200 | 3-5 | 1.5 | 310 | 740 | 740 | 850 |

3MZ-200 | HMS | 3 | 200 | <15 | 120-200 | 3-5 | 1.5 | 310 | 740 | 740 | 850 |

4MZ-200 | HMS | 4 | 200 | <15 | 120-200 | 3-5 | 1.5 | 310 | 740 | 740 | 850 |

2MZ-400 | HMS | 2 | 400 | <15 | 120-200 | 3-5 | 1.5 | 310 | 740 | 740 | 850 |

3MZ-400 | HMS | 3 | 400 | <15 | 120-200 | 3-5 | 1.5 | 310 | 740 | 740 | 850 |

1MZ-1000 | HMS | 1 | 1000 | <12 | 120-250 | 3-5 | 1.1 | 350 | 740 | 740 | 910 |

LMZ-120 | sieve | 1 | continuous | <15 | 120-250 | 120 g/s | 1.1 | 350 | 510 | 510 | 1000 |

LMZ-1000 | sieve | 1 | continuous | <15 | 120-250 | 120 g/s | 1.1 | 380 | 510 | 510 | 1000 |