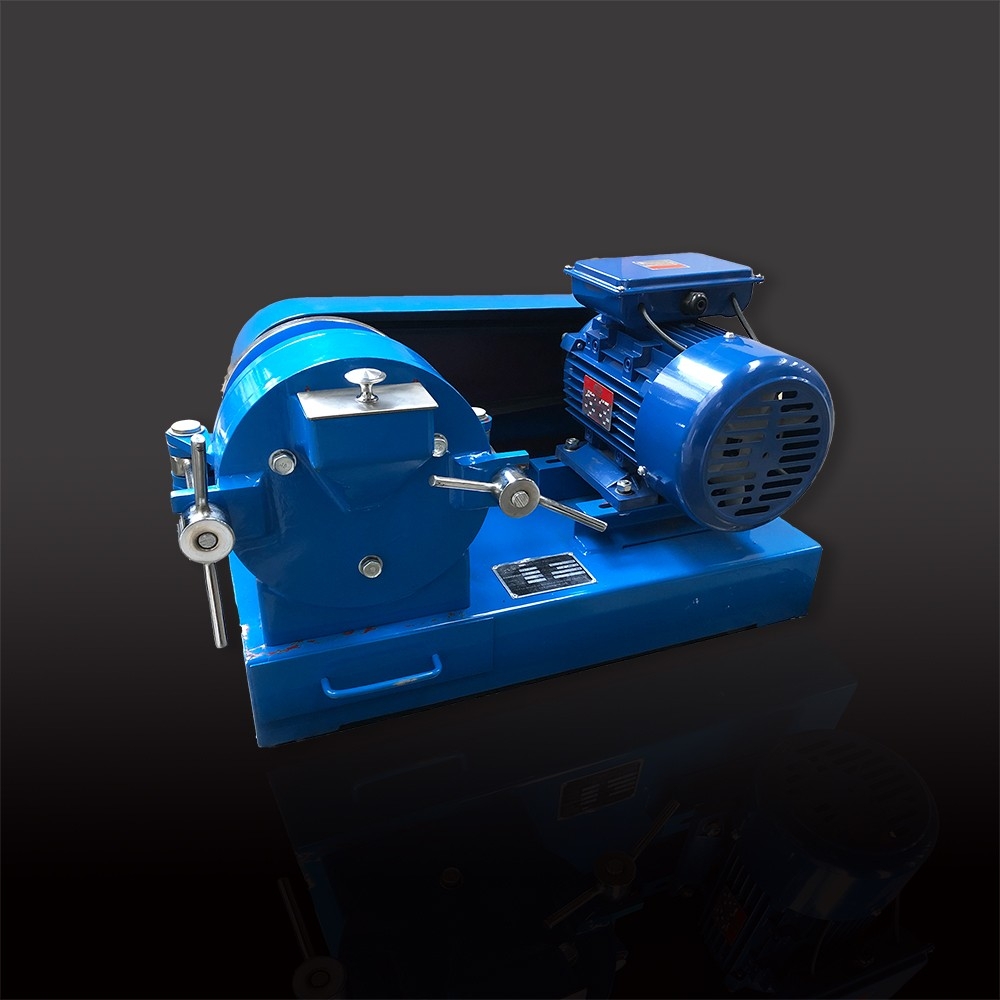

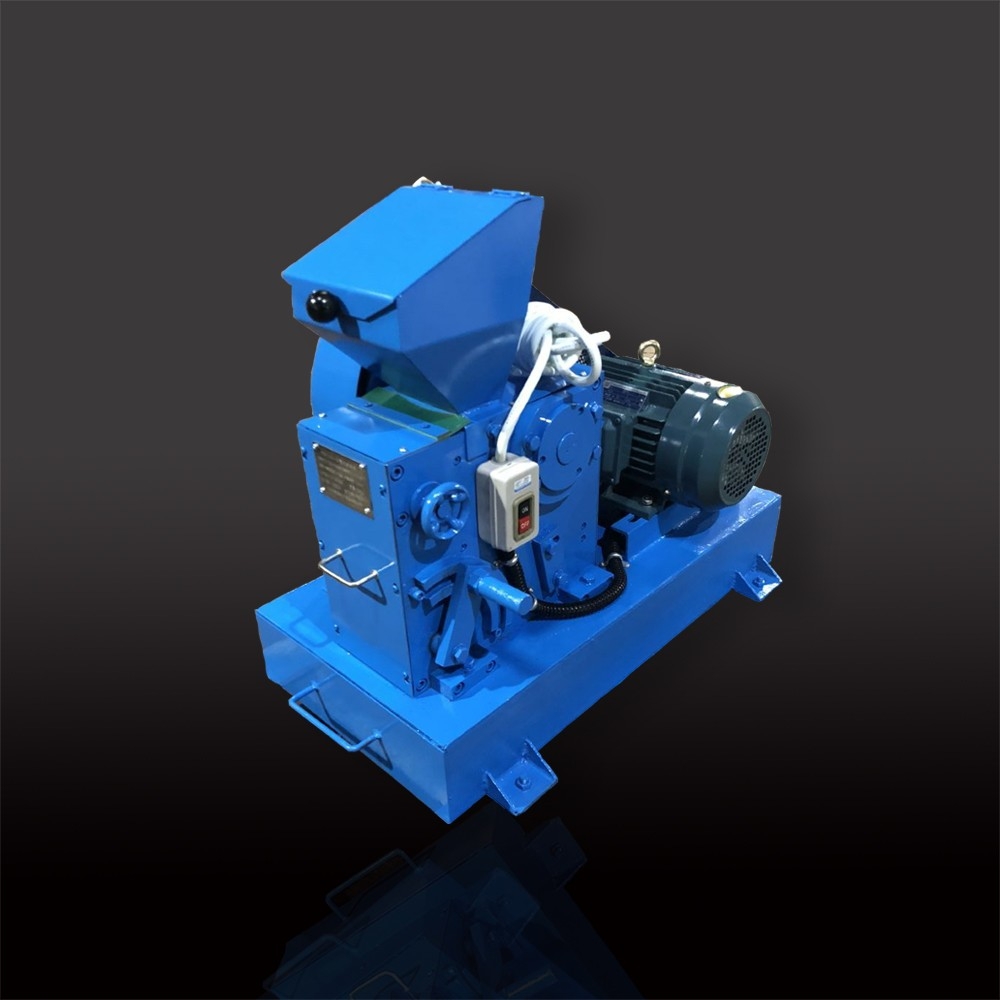

Lab Disc Pulverizer

GTEK Laboratory Disk Mill or Laboratory Disc Pulverizer can be used for intermittent and continuous fine grinding of hard-brittle and medium-hard materials in the field of mining and metallurgy, glass industry, ceramics industry.

Description

| Laboratory Disk Mill or Laboratory Disc Pulverizer can be used for intermittent and continuous fine grinding of hard-brittle and medium-hard materials in the field of mining and metallurgy, glass industry, ceramics industry.There are three different models available with disc plate size 150mm,175mm and 250mm.The maxi-mum feed particle size is 2 to 6 mm. The fineness attainable is down to 80 mesh.This disc pulverizer is easy to maintain and can pulverize efficiently a wide variety of materials.The grinding discs are made of a special alloy combining strength and toughness, thus assuring wearing quality; and their special design with large and small lugs secures the highest efficiency. |

Disc Pulverizer Grinding Effect

Magentic Buckle

Working Principle The material is fed to the disc pulverizer and pulverized between a stationary disk plate and a moving disc plate by compressive and shearing action.The desired final fineness can be adjusted for by means of the rotating the hand wheel. The machine can be opened in one side so that it can be cleaned easily with a brush. |

Features

1. Wide range of materials for contamination free grinding;

2. Reproducible results due to accurate gap setting;

3. HMS grinding discs with long working life;

4. No foundation bolt is required.

Model | Φ150 | Φ175 | Φ250 |

Feeding Size (mm) | ≤2 | ≤3 | ≤6 |

Discharging Size (mesh) | 80 | 50 | |

Main Shaft Speed (rpm) | 1050 | 1050 | 800 |

Throughput (kg/h) | 6-20 | 10-35 | 20-100 |

Dimensions (mm) | 550×490×365 | 550×490×365 | 770×510×500 |

Weight (kg) | 90 | 130 | 180 |

Power (kW) | 1.1 | 1.5 | 2.2 |